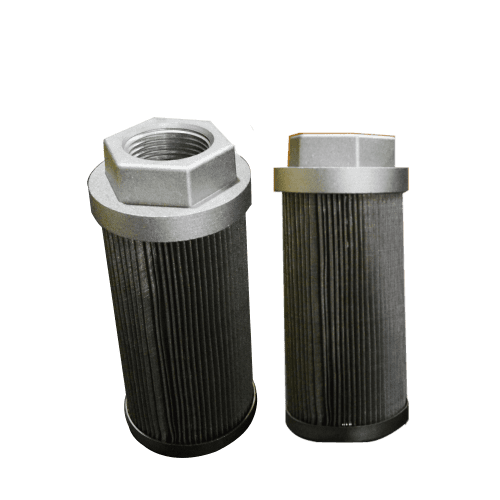

Hydraulic Filter

Are there dirt or unwanted particles clogging your hydraulic system? Get a hydraulic filter at the best price to remove these impurities!

Hydraulic Filter

- High Quality Materieals

- Compliance with Standards

- Clear product information

- Warranty & Supports

- Product testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

DESCRIPTION

About Hydraulic Filter

The hydraulic filter is a crucial component in a hydraulic system – its primary task is to remove impurities like dirt, metal particles, and water residue from hydraulic fluids. The filter is the popular choice for preventing wear and tear of hydraulic components, and maintain the hydraulic system’s proper operation while extending its years of service.

The market generally offers two kinds of hydraulic filters:

- Full-flow filters which exist at the inlet to the hydraulic pump and

- Suction filters typically found in the hydraulic reservoir.

While the hydraulic filter efficiently does its job of protecting most of a system’s components, it is essential to replace the filter from time to time in they stop functioning effectively. This means regular inspection and stricter maintenance!

Key Features of Hydraulic Filter

There are many unique features the hydraulic filter has, thereby staying a relevant product in the field of hydraulics for years and years. Some of its visually prominent characteristics are:

The filter element: This is the heart of the filter and is typically a porous material by nature (cellulose, fiberglass, or metal mesh,) with different pore sizes to capture contaminants from the hydraulic fluid. It is the gate through which no unholy particle can pass!

The filtration rating: This rating determines the size of the smallest contaminant it can extract from the hydraulic fluid. The micron value (μm) reflects this rating.

The dirt holding capacity: This reflects the quantity of contaminants the filter can actively hold before losing its efficiency. Potential hydraulic filters owners always look for a higher holding capacity so that the filter requires less periodic maintenance!

The pressure drop option: The pressure drop reflects the decrease of press when the hydraulic fluid navigates through the filter. If your filter manages to minimize the pressure drop, consider your system working fit and fine.

The flow rate: This refers to the maximum fluid flow it can handle per unit of time. This specification is necessary; it determines if the filter can keep up with the demands of the system!

The universal compatibility: The filter can also provide a lot of compatibility as it can work with both mineral-based oils and water-based fluids.

Besides these most important features, some other offerings from the hydraulic filter include its heavy resistance to harsh elements, easy-to-install and easy-to-repair processes, and world class safety features adorned with industrial certifications.

Working Procedure of Hydraulic Filter

The porous material in the hydraulic filter is where the main action occurs, giving meaning to the overall working procedure. The pore size determines the capacity to handle the contaminant size, and the filter manages to do this via a streamlined process:

- First the contaminated hydraulic fluid enters the filter through an inlet port.

- The fluid does not stop here; it passes through the filter in a steady flow.

- During this process, the contaminants cannot exit the filter along with the fluid; they stay behind, trapped in the pores.

- Meanwhile, the fluid that comes out of the other side of the hydraulic filter is pure and clean, fit for the hydraulic system.

- When the filter becomes full of contaminants, its filtration efficiency decreases. Therefore, period replacement or regular maintenance is necessary to retain the optimal filtration performance.

Several factors play a crucial role in determining a hydraulic filter’s capabilities, such as the filtration rating, the hydraulic flow rate, and the type of contaminants present in the hydraulic fluid.

Applications of Hydraulic Filter

The hydraulic filter is no longer an alien product; it has improved leaps and bounds to become a crucial component of most hydraulic systems operating across various industries today. Its range of usage-case scenarios include:

Construction Equipment: Excavators, bulldozers, cranes – all sorts of construction equipment have the filter installed into them to maintain proper hydraulic fluid flow.

Industrial Machinery: The filter also exists in industrial machinery from presses to manufacturing equipment, and from lifts to conveyors. It prevents machines from malfunctioning and extends equipment lifespan.

Automotive Industry: In this industry, it enhances automotive systems such as power steering, brake systems, and suspension systems.

Research and Development: Laboratory and research experiments use the filter to measure and monitor the pressure levels of various types of hydraulic fluids.

Aerospace and Aviation Systems: In aerospace, the filter ensures safe and reliable operation of aircraft control systems, landing gear, and other hydraulic actuated mechanisms.

Renewable Energy Systems: In the field of renewable energy, the filter is a mainstay in wind turbines, solar tracking systems, and geothermal power plants.

Some more prominent areas of interest that cannot live without the hydraulic filter are the marine industry, agriculture industry, and fluid power systems, etc.

Advantages of Hydraulic Filter

There are crazy advantages to gain if your hydraulic system has an integrated hydraulic filter. First, not only will it reduce the wear and tear of other hydraulic components, it will also improve system efficiency and prevent unnecessary energy consumption.

It will minimize the risk of system failure and will additionally extend the lifespan of the hydraulic fluid. This means the fluid does not have to go through frequent replacement, cutting down more costs. By design, the hydraulic filter is also hellbent on providing productivity, quality control, and safety for various applications.

The most unique benefits to finally avail from this technical marvel are its environmentally friendly operation, cost-effective maintenance solutions, and its wonderful capacity to improve diagnostics while reducing troubleshooting periods.

Why Choose Lotus Traders

If you are reading this article, you are probably wondering about buying a hydraulic filter soon. But if you do not have a clearer idea of the prices beforehand, you may find yourself shorthanded when it comes to dealing with the market’s shopkeepers.

Lotus Traders has a dedicated research team that keeps track of the market fluctuations from time to time. If you are looking for a simple hydraulic filter, the prices will start from Rs. 400. But if you want to spend more, prices can go up to Rs. 4000 for a Duramax hydraulic filter. There are much more expensive offerings, such as Eaton hydraulic filters going for a current sale value of Rs. 35, 000! These prices have a wide margin between them because they complement different hydraulic systems.

If you are not entirely sure which hydraulic filter suits your hydraulic system, Lotus Traders is here to help. Contact us today for further assistance!

Frequently Asked Questions

The hydraulic filter has one major role to play – it removes impurities like dirt, metal particles, and water residue from most hydraulic fluids. This filter is the industrial standard for preventing wear and tear of all hydraulic components, and maintaining the hydraulic system’s proper operation while extending its years of service.

The primary hydraulic filter HSN code is 8421.

The current market generally offers two kinds of hydraulic filter types:

- Full-flow filters – these filters exist at the inlet to the hydraulic pump.

- Suction filters – these filters typically exist in the hydraulic reservoir.

Thy hydraulic filter symbol that represents effective filtration rating is the micron value (μm). This rating determines the size of the smallest contaminant it can extract from the hydraulic fluid.

The primary hydraulic filter elements that makes it resistant to the most extreme working conditions are micro-fiberglass, polyester, or phenolic-impregnated cellulose.

While it is a far fetch to term any manufacturer as the best, Lotus Traders has consistently delivered supreme quality products all-over North-East India since the past fourteen years. Therefore, if you need any kind of construction-related equipment that will last for many years, contact us to get in touch today!

A hydraulic filter press is available for sale at Lotus Traders, a construction equipment supplier based in Zoo Road, Guwahati, Assam. We deal in every kind of hydraulic equipment and will gladly provide you a tour of our best products!

Once you buy a hydraulic filter machine from Lotus Traders, its aftersales service kicks into gear, meaning you can ask for conventional repairs down the road if you are facing problems with the newly purchased product. Therefore, rest assured once you finalize the decision to purchase from us!

The hydraulic filter clogging indicator exists in the filter housing. This device trips once the filter’s dirt holding capacity reaches its maximum potential, which will result in an alarm before it becomes fully clogged. This is a crucial device that warns operators when it is time to replace the filter before any harm to the hydraulic system occurs.

Lotus Traders has the best hydraulic filters available in the market. Our products are innovative and built with the initial backdrop of making them accessible for varying degrees of customers. Get a price quote on our website today!