Brick Making Machines

MANUAL BRICK MAKING MACHINE

A manual brick making machine is a simple cost-effective device designed for small-scale brick making and operated by manual labor without power and complicated automation. This can be an ideal solution for local or community-based projects among which the scale of production is low. The manual brick making process entails hand loading the raw materials, which mostly are clay or a mixture of concrete, to the machine’s molds.

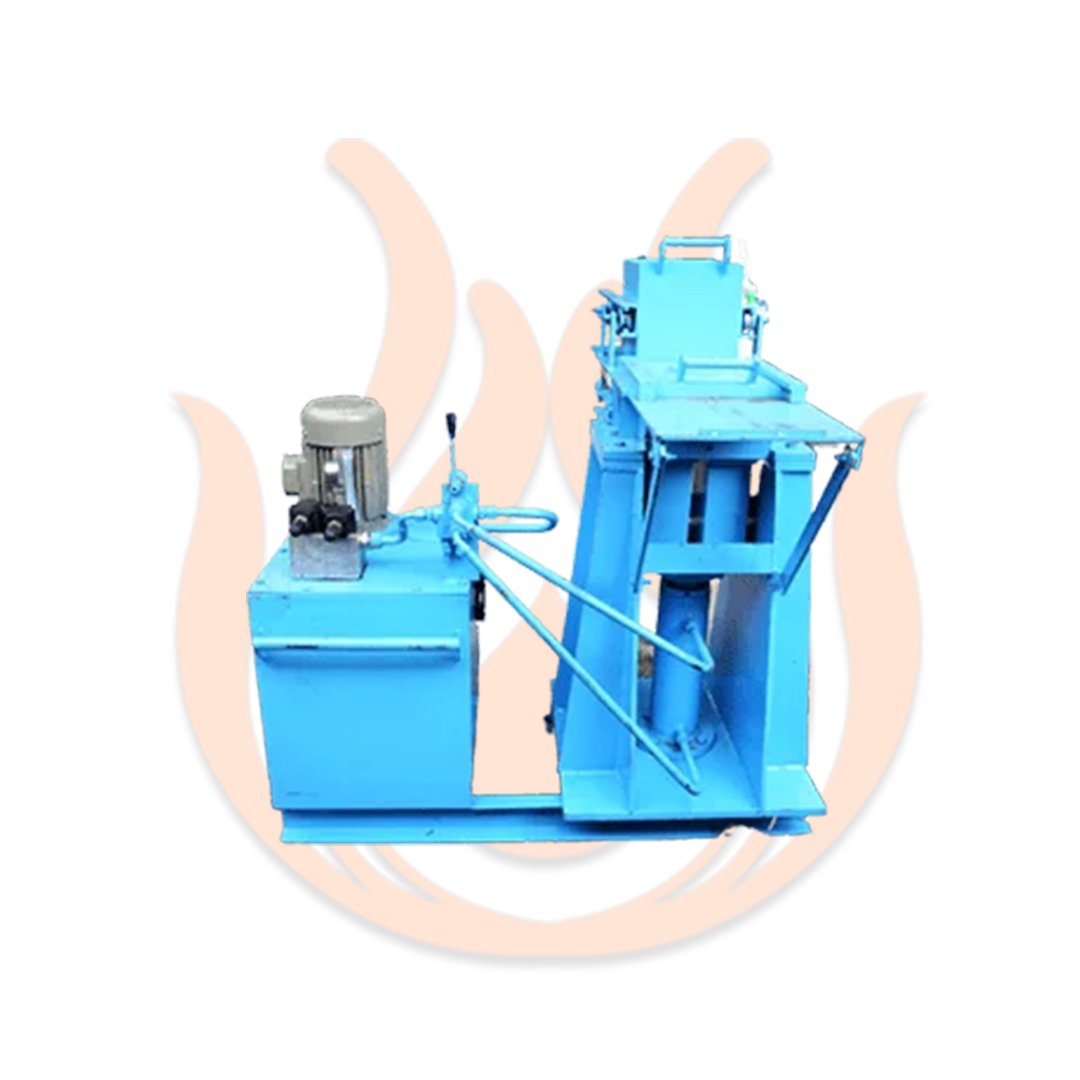

SEMI AUTOMATIC BRICK MAKING MACHINE

A semi- automatic brick-making machine is a medium-level construction equipment that combines the manual and automatic procedures in order to boost the efficiency and productivity. Unlike fully manual machines, semi-automatic models have automated steps in some stages of the brick-making process. Generally, raw materials like clay or concrete are manually loaded into the machine; and the molding and compression processes are partially automated.

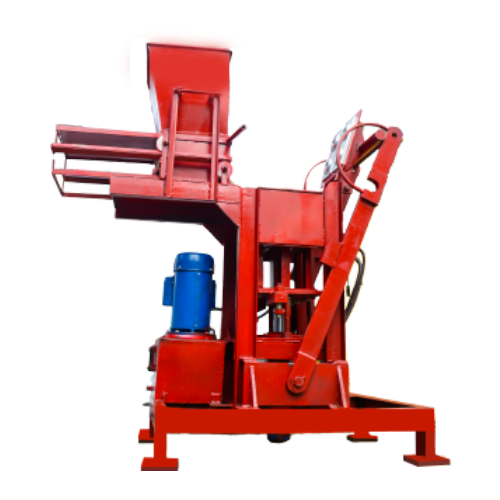

AUTOMATIC BRICK MAKING MACHINE

It’s a machine which make minimum order quantity in one unit production…

A brick manufacturing machine is an industrial automated equipment for efficient and large-scale brick production with limited manual involvement. This type of machine is fitted with up to date automation capabilities such as the feeding of raw materials, mixing, molding, and brick ejection. The entire process of bricks making is geared towards speed and accuracy. Automatic brick-making machines are usually featured with computerized controls, sensors, and hydraulics to ensure the consistent quality output. These machines perform very good for industrial-sized projects which need high throughput and standardized brick quality.

Frequently Asked Questions

Most manual brick making machine can produce 1 or 2 bricks every cycle however Lotus traders manual brick making machine can operate 4 bricks in every press and in one shift, a manually operated brick-making machine is capable of turning out 1000 to 2000 bricks

The typical wholesale rate for Manual Brick Making Machines price in India is between Rs ₹40,500 and Rs ₹77,000.

A manual brick making machine is a simple and cost-effective device designed for small-scale brick production. It is operated by human labor without the need for electricity or advanced automation. The process involves manually loading raw materials, compressing them into molds, and air or sun-drying the formed bricks.

A semi-automatic brick making machine is an intermediate-level device that combines manual and automated processes. While raw materials are still manually loaded, the molding and compression stages are partially automated. Semi-automatic machines strike a balance between cost-effectiveness and increased production capacity, making them suitable for small to medium-scale projects.

An automatic brick making machine is a sophisticated construction device designed for large-scale production. It incorporates advanced automation features, including automatic raw material feeding, mixing, molding, and brick ejection. Equipped with computerized controls, sensors, and hydraulic systems, these machines ensure consistent quality and output, making them ideal for industrial-scale projects.

Automatic brick making machines are preferred for large-scale industrial projects where high production rates, standardized brick quality, and minimal manual labor are crucial. These machines are optimized for speed, precision, and efficiency, making them ideal for extensive construction ventures.

Machine made bricks are usually used for large scale construction building since they can be manufactured massively and affordably in a large scale. For projects with a traditional or historic architectural style, regular bricks, which are handmade and distinctive, give a robust look and it take more labour work. The decision is based on the project’s requirement and financial constraints.

In India, the standard size of a brick is typically 9 x 4.5 x 3 inches (Length x Width x Height).

The most suitable brick making machine to choose will rely on several of things, including your particular requirements, your budget, and your desired output. Manual, semi-automatic, and fully automatic brick-making machines are some common varieties; each has benefits. A manual or semi-automatic machine may be sufficient for beginning or small scale projects. However, a fully automatic machine is more efficiency for larger scale manufacturing of the bricks. When choosing the ideal brick making machine for your purposes, it is crucial to do research and take into consideration your specific needs and goals.