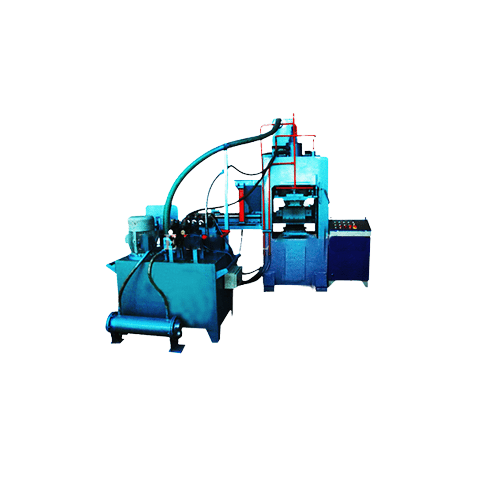

high pressure automatic block machine double cavity

Automatic Block Machine

High Pressure Double Cavity Automatic Block Machine

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Production Capacity | 375 Blocks per hour / 500 Bricks per hour |

Cavity | Block 2 / Bricks 3 |

Block Type | Solid |

Method | Hydraulic Pressure |

Power Requirement (machine+mixer+conveyor) | 14 KW 440v |

Pressure | 3000 PSI |

Belt Conveyor | 16ft |

Pan Mixer 1 Number | 380Kg Capacity |

What is Double Cavity Automatic block machine?

An automatic double cavity block making machine is a device that produces paving stones, solid blocks and hollow blocks made of concrete. This fully automated machine compresses a mixture of water, sand and concrete into moulds using hydraulic pressure. Due to its two chambers the machine can simultaneously make two blocks.

There are several benefits that the automatic double cavity block forming machine offers over the manual and semi-automatic models. It generates more uniform blocks and is faster and more efficient. Additionally, there is less maintenance required and the machine is simpler to use.

Key features of Double Cavity Automatic Block Machine

An automatic double cavity block forming machines key features are:

Complete automation: No human involvement is needed for the machine to function. From mixing the concrete to ejecting the completed blocks, every stage of the block making process is automated.

Hydraulic Pressure: Concrete is compressed into the moulds by use of hydraulic pressure which is applied by the machine. This guarantees a high density and appropriate compacting of the blocks.

Dual cavity: The machine can make two blocks at once since it has two cavities. This raises the machines manufacturing capacity.

PLC monitoring: A programmable logic controller (PLC) is in charge of the apparatus. This makes it possible to precisely control every function of the machine.

Simple operation: Maintaining and operating the equipment is a breeze. All of the parts are easily accessible and the control panel is easy to use.

Some additional features of automatic double cavity brick making machine include mould shapes in variety, adjustable vibrating frequency, automated curing system (ACS), security measures, etc.

Benefits of Double Cavity Automatic block machine ?

Automatic double cavity block making machines have a number of benefits over manual and semi-automatic block making machines, including:

Enhanced production capacity: Compared to manual or semi-automated block making machines, automatic block making machines may generate hundreds or thousands of blocks per hour a significant increase in output.

Increased product quality: Automatic double cavity block producing machines generate blocks that are more reliable and of a higher caliber.

Reduced labour expenses: Automatic double cavity block making machines require less manpower to operate which can result in significant labour expense savings for businesses.

Increased protection: Automatic double cavity block making machines are safer to use due to its machines ability to automate a large number of block making activities which lowers the possibility of mishaps.

Double cavity design: The double cavity design boosts the machines production capability by enabling it to generate two blocks simultaneously.

Control: PLC control systems enable accurate control over every aspect of the machines operation leading to better quality blocks with fewer flaws.

Simple maintenance and operation: Even for staff with little expertise, automatic double cavity block making machines are simple to use and maintain.

Variety of mould shapes: To create various kinds of blocks including hollow blocks, solid blocks and paving stones the machine can be fitted with a range of mould shapes.

Dynamic vibration frequency: By varying the machines vibration frequency blocks with varying densities and strengths can be produced.

Automatic curing system: After the blocks are evacuated from the machine can be fitted with an automatic curing system to cure them. The blocks become stronger and more resilient as a result.

Safety features: The machine has several safety measures including overload prevention and emergency stop buttons. This lessens the likelihood of mishaps and injury.

Uses of Double Cavity Automatic block machine ?

Automatic double cavity block making machines are used in a variety of industries such as:

Constructions: Concrete blocks for a range of construction projects including residential and commercial structures, highways and bridges and retaining walls are produced using automatic double cavity block making machines.

Landscaping: Concrete blocks for landscape projects like patios, walks and driveways are made by automatic double cavity block making machines.

Paving: Concrete blocks are produced by automatic double cavity block making machines for use in roadways, parking lots and walkways.

Hollow blocks, Solid blocks, Paving stones: Hollow blocks are perfect for use in construction projects since they are energy efficient and lightweight. Depending on the particular requirements of the project, automatic double cavity block making machines that can generate hollow blocks in a range of sizes and shapes.

Solid blocks are perfect for use in heavy duty applications like retaining walls and bridge construction because they are robust and long lasting. Various sizes and shapes of solid blocks can be produced by automatic double cavity block making machines based on the particular requirements of the project.

Patios, pathways and driveways can be made into visually appealing and long lasting surfaces with the use of paving stones. Paving stones in a range of sizes, shapes and colors can be produced by automatic double cavity block making machines to accommodate any taste or budget.

Affordable housing: In underdeveloped nations, affordable housing materials can be produced utilizing automatic double cavity block making machines. An economical and long lasting substitute for conventional building materials like brick and wood are concrete blocks.

Uses of automatic double cavity block making machine

Automatic double cavity block making machines are used in a variety of industries such as:

Constructions: Concrete blocks for a range of construction projects including residential and commercial structures, highways and bridges and retaining walls are produced using automatic double cavity block making machines.

Landscaping: Concrete blocks for landscape projects like patios, walks and driveways are made by automatic double cavity block making machines.

Paving: Concrete blocks are produced by automatic double cavity block making machines for use in roadways, parking lots and walkways.

Hollow blocks, Solid blocks, Paving stones: Hollow blocks are perfect for use in construction projects since they are energy efficient and lightweight. Depending on the particular requirements of the project, automatic double cavity block making machines that can generate hollow blocks in a range of sizes and shapes.

Solid blocks are perfect for use in heavy duty applications like retaining walls and bridge construction because they are robust and long lasting. Various sizes and shapes of solid blocks can be produced by automatic double cavity block making machines based on the particular requirements of the project.

Patios, pathways and driveways can be made into visually appealing and long lasting surfaces with the use of paving stones. Paving stones in a range of sizes, shapes and colors can be produced by automatic double cavity block making machines to accommodate any taste or budget.

Affordable housing: In underdeveloped nations, affordable housing materials can be produced utilizing automatic double cavity block making machines. An economical and long lasting substitute for conventional building materials like brick and wood are concrete blocks.

How the automatic double cavity block making machine works?

Using hydraulic pressure an automatic double cavity block forming machine compresses a combination of concrete, sand and water into moulds. Because the machine has two chambers that can simultaneously make two blocks.

The operation of an automatic double cavity block forming machine can be outlined in the following steps:

- In a pan mixer, the raw materials—concrete, sand and water are combined.

- A conveyor belt is then used to feed the mixed concrete into the block manufacturing equipment.

- Using hydraulic pressure, the machine compresses the concrete into the moulds.

- The blocks are discharged from the machine onto a pallet once they have been formed.

- After that the block pallets are cured in a curing yard or steam chamber.

Concrete is compressed with a very high hydraulic pressure usually between 200 to 300 PSI. This guarantees a high density and appropriate compacting of the blocks. Additionally, the machines vibration frequency can be changed to generate blocks with varying densities and strengths.

The blocks can be cured in a curing yard or steam chamber after being removed from the machine. The blocks become stronger and more durable after curing.

Automatic double cavity block making machines are incredibly productive; they can turn out thousands or even hundreds of blocks in a single hour. Additionally, they are not too difficult to maintain and operate.

For medium scale block production, an automated double cavity block forming machine is a modern technology that effectively produces two blocks at once. It minimizes manual intervention by streamlining the entire production process from material feeding to block discharge through high automation. It greatly increases efficiency with its faster output and larger production capacity which makes it perfect for organizations with expanding needs. It guarantees adaptation to different construction needs by providing variety in block kinds and sizes. Its increased efficiency and automation make it a significant asset for medium- to huge scale construction projects even though its initial investment may be higher than that of semi automatic models.

Concrete Mixer Machine With Lift

Manual 4 Cavity Brick Machine

Egg Laying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator