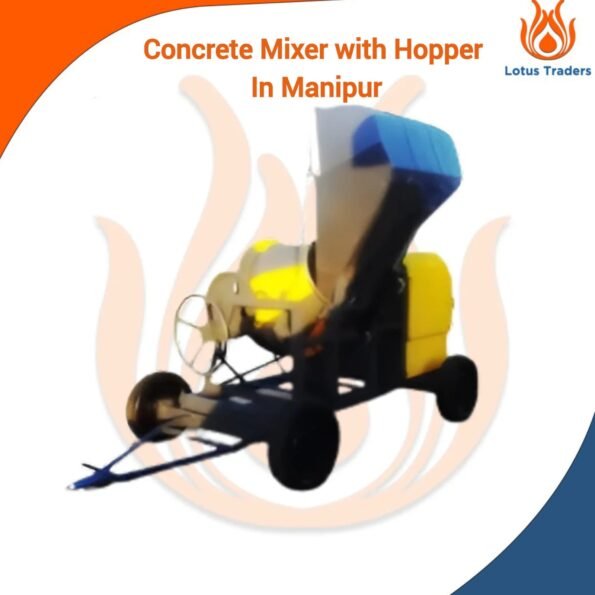

Concrete mixer with Hopper in Manipur

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

What is Concrete Mixer with Hopper in Manipur?

A Concrete Mixer with Hopper in Manipur is an essential piece of construction machinery designed for efficiently mixing concrete by combining cement, sand, aggregates, and water in a rotating drum. It is equipped with an integrated hopper, which is a specially designed funnel-like structure that facilitates the automatic or semi-automatic loading of raw materials into the mixing drum. This feature significantly reduces manual labor, improves operational efficiency, and ensures a more consistent and homogenous concrete mix.

Key Features and Functionality of Concrete Mixer with Hopper in Manipur

Hopper Mechanism – The hopper is one of the most crucial components of this mixer, as it allows for easy and precise loading of materials. It operates either through a mechanical lever system or a hydraulic lifting mechanism, depending on the model. The materials are first loaded into the hopper, and once filled, it is lifted and emptied into the mixing drum with minimal human effort.

Mixing Drum – The heart of the machine is the rotating drum, where all the ingredients are mixed thoroughly. The drum is usually made of heavy-duty steel, ensuring durability and long-lasting performance. It operates on a tilting or non-tilting mechanism, allowing for easy discharge of mixed concrete when ready.

Power Source – Concrete mixers with hoppers are powered either by an electric motor or a diesel engine, depending on the site requirements and availability of electricity. Diesel-powered mixers are preferred for remote construction sites where electricity supply may not be reliable.

Capacity – These mixers come in various sizes, with the most common being 10/7 CFT and 14/10 CFT models. The 10/7 CFT model means it can hold 10 cubic feet of dry materials and produce 7 cubic feet of wet concrete per batch. Larger capacity mixers are also available for high-volume projects.

Hydraulic Lifting System (Optional Feature) – Some advanced models include a hydraulic lifting mechanism that enhances the efficiency of the hopper, making the loading process even smoother and more controlled. This system reduces wear and tear on mechanical parts and extends the machine’s operational life.

Portability & Mobility – Many concrete mixers with hoppers are mounted on wheels, allowing easy transportation from one location to another within a construction site. Some variants come with tow bars, enabling them to be attached to vehicles for easy movement.

Advantages of a Concrete Mixer with Hopper in Manipur

Increased Efficiency – The automated loading system ensures a continuous mixing process, reducing downtime and manual intervention.

Reduced Labor Costs – By eliminating the need for manual loading, it significantly cuts down on labor costs.

Consistent Mixing Quality – Ensures uniform and homogeneous mixing of concrete, leading to stronger and more durable structures.

Time-Saving – Faster operation compared to traditional manual mixing methods, allowing for quicker project completion.

Cost-Effective – Reduces material wastage and optimizes resource usage, making it an economical choice for construction projects.

Applications

A Concrete Mixer with Hopper is widely used in various construction projects, including:

Building Construction – Ideal for mixing concrete for columns, slabs, and foundations.

Road Construction – Used in laying concrete for pavements, bridges, and highways.

Infrastructure Projects – Suitable for large-scale infrastructure development such as flyovers, tunnels, and dams.

Precast Concrete Manufacturing – Helps in producing precast concrete blocks, pipes, and other structural elements.

Why buy Concrete Mixer with Hopper in Manipur ?

Investing in a Concrete Mixer with Hopper in Manipur can bring significant advantages to your construction business, improving efficiency, reducing costs, and enhancing the quality of your concrete production. Here are the key reasons why you should consider purchasing one:

1. Increased Efficiency & Faster Operation

The integrated hopper enables quick and effortless loading of raw materials, significantly reducing manual labor.

The automated or semi-automated process speeds up concrete mixing, allowing for faster completion of projects.

A consistent mixing process ensures uniform concrete quality without frequent interruptions.

2. Reduces Labor Costs & Dependence on Skilled Workers

With an automatic hopper, there is less need for manual loading, reducing the number of workers required.

Minimizes physical strain on workers, leading to a safer and more productive work environment.

Easy operation means it doesn’t require highly skilled labor to run the machine efficiently.

3. Ensures High-Quality & Consistent Concrete Mix

The rotating drum provides a uniform mix of cement, sand, aggregates, and water.

Eliminates inconsistencies and variations that often occur with manual mixing methods.

Produces stronger and more durable concrete, reducing the risk of structural defects.

4. Cost-Effective & Reduces Material Wastage

The precise loading mechanism minimizes spillage and material wastage.

Faster mixing cycles mean less fuel and electricity consumption per batch.

An efficient batching process ensures the correct ratio of materials, reducing unnecessary expenses.

5. Suitable for Various Construction Projects

Ideal for small, medium, and large-scale projects, including:

Residential & Commercial Buildings

Road & Bridge Construction

Dams & Infrastructure Projects

Precast Concrete Manufacturing

Portable models allow easy transportation to different project sites.

6. Versatile Power Options (Diesel or Electric)

Diesel Engine Models: Ideal for remote sites where electricity supply is unreliable.

Electric Motor Models: Perfect for urban and industrial settings with stable power connections.

7. Durable & Long-Lasting Investment

Made from heavy-duty steel and designed for rough construction environments.

Low maintenance costs compared to traditional manual mixing methods.

Many models come with hydraulic systems that extend the lifespan of mechanical components.

8. Saves Time & Increases Productivity

A single batch can produce 7-10 cubic feet of concrete, depending on capacity.

Reduces mixing time per batch compared to traditional drum mixers.

Helps meet project deadlines efficiently, preventing costly delays.

Why choose Lotus Traders for Concrete Mixer with Hopper in Manipur ?

Choosing Lotus Traders for your Concrete Mixer with Hopper in Manipur offers several compelling advantages:

Comprehensive Product Range

Lotus Traders offers a wide array of construction machinery, including various models of Concrete Mixers with Hoppers. This extensive selection allows you to choose equipment that best fits your project’s specific needs.

Commitment to Quality and Innovation

Prioritizing customer satisfaction, Lotus Traders focuses on delivering durable, efficient, and innovative construction solutions. Their products are designed to withstand rigorous use, ensuring long-term reliability and performance.

Customer-Centric Approach

Lotus Traders emphasizes transparency, integrity, and building lasting relationships with clients. Their dedicated team provides clear communication, comprehensive product information, and responsive support, ensuring a seamless purchasing experience

In summary, Lotus Traders combines extensive experience, a broad product range, unwavering commitment to quality, strategic regional presence, and a customer-focused approach, making them a reliable choice for procuring Concrete Mixers with Hoppers in Manipur.