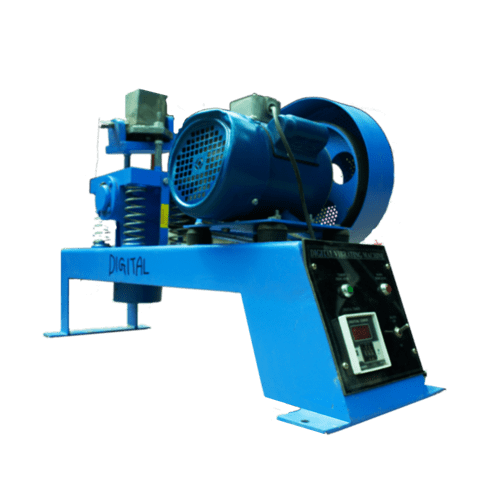

Digital Cube Vibration Table

Digital Cube Vibration Table

- High Quality Materials

- Compliance With Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Usage/Application | Laboratory |

Driven Type | Motor |

Material | Iron |

Max Weight | 200kg |

Max Vibration | 12000+/-400 vibration per min |

Cube size | 70.6 mm |

Digital cube vibration table:

Achieving high quality cement with digital precision.

Building a strong and dependable project is imperative in the construction world for creating secure and long-lasting structures. An improved system for the assessment of cement and the digital cube vibration table is considered as the most sophisticated tool for the testing of concrete cube Testing. This piece of equipment allows us to use digital devices to measure precisely the strength of the concrete and make sure that it corresponds to the required values. The introduction prepares the reader for the significance and advantages of using the digital vibration cube on construction sites.

Understanding a Digital Cube Vibration Table

A digital cube vibrations table is a special equipment used for putting pressure on and vibrating the concrete cubes during simulation of actual circumstances to assess the resistance level. This modern equipment features digital controls and observes as it applies vibration accurately and consistently enough to enable adequate evaluation of the concrete’s resistant capacity. The incorporation of digital technology improves the reliability of testing as well as the possibility of instantaneous data capture and analysis which can inform construction industry personnel on conformity of the concrete properties for different construction settings. Digital Compression testing machine.

Key features Digital Cube Vibration Table

Digital cube vibration table is suitable for all forms of laboratories and sites; its powerful motor enables this machine to create massive and consistent vibrations of 12000+/-400 per minutes. This machine is capable to handle the max weight of 200+ kg with the maximum cube size of 70.6mm. its complete iron built provides a robust built quality to withstand every condition of constructional environment.

Working of a Digital Cube Vibration Table

The equipment’s working is started by Placing a concrete cube sample on a vibrating platform which is then activated by controlling digital vibration, the table forms the essence of vibration into the cube for further stimulation and assessment. The equipment uses controlled vibrations on concrete cube at various frequency and strengths thus stimulating those experienced vibrations in real life conditions.

Digital monitoring devices, such as piezometers and crack meters, record and analyse the information obtained through the testing process. Such information refers to the concrete’s compressive strength and its resistance to external pressure or load. The comprehensive testing process in this case certifies the fact that the product meets the required market standards as well as legal specifications appropriate for structures with enhanced reliability and stability needed on construction sites.

Significance in cement testing:

A digital cube vibration table is crucial in concrete testing because it offers true results concerning the strength and characteristic features experienced by different concrete cubes. This state-of -the-art equipment replicates actual field condition in order help the construction professions ascertain the concrete resistance to deterioration and durability and ensure its conformity with the set quality standard. Digital cube vibration test results aid in optimizing the concrete composition which makes superior quality concrete for structures such as residential building and infrastructural development like bridges.

Advantages of digital cube vibration testing:

Digital cubic vibration test is more precise, more efficient, and less complicated when it comes to generating the results. Inclusion of digital technology makes testing very accurate and uniform across diverse instances thereby reducing deviation. Additionally, real time data monitoring and evaluation enables construction engineers to take instant appropriate decisions on the quality and adaptability of the concrete for project uses. Standardized testing processes associated with a digital cube vibration table assist ensure in a strong and durable concrete.

Usage of digital cube vibration table in modern construction projects:

In modern constructions that require high quality and long-lasting concrete, various engineering applications are used including the use of the digital cube vibration table. This makes it possible to determine the most suitable concrete type for foundations, columns, beams, and slabs depending on their intended purposes, including their performance characteristics and compressive strength when used for testing concrete cubes in construction. The results from digital cube vibration testing are used for optimal concrete mix designing such that the produced concrete addresses particular needs of individual projects thus supporting durable infrastructure development.

This selection of Lotus Traders as a distributor of the digital cube vibration table gives customers the advantage of modern technologies in the production area of concrete testing. Lotus Traders promises quality and customer care by offering reliable equipment for the concrete testing procedure. On the contrary, using the digital cubic movement platform provided by Lotus Traders can provide the construction professionals with high level of accuracy in their assessment of the strength of concrete they are dealing with. The commitment by lotus traders, towards innovation and excellence leads to enhanced productivity and provision of high-quality concrete, hence they stand out as the top solution providers within the construction equipment industry.

Frequently Asked Questions

A vibration table is used to fix the compaction of material during packaging, a vibration table is also used to stimulate the vibration that may arise in real life situation to examine the strength and sturdiness of cement blocks or cube.

Vibrating concrete is crucial for removing air content and air pockets within the concrete to increase the density and strength of the concrete. Tightly packed particles will result in a stronger and more durable concrete structure.

The universal size of a cement cube mould as per ISI is: 70.6 x 70.6 x 70.6

A digital cube vibration table operates by vibrating cube at a controlled vibration, stimulating real-world situations to assess their strength and resilience accurately.

Yes, different sized cubes can be used for vibration testing.

What are the advantages of using the digital cube vibration table?

Digital cube vibration test can be performed depending upon the scale and requirement of the construction projects, typically, it is performed during various stage of construction to ensure that the cement meets the necessary strength and durability standards.

The digital cube vibration table enhances projects efficiency by providing accurate and quick data about concrete strength and durability, enabling construction professionals to make precise decision about the suitability of concrete for various projects, thus saving a lot of time and enhancing projects quality output.

The digital cube vibration table accurately assesses the comprehensive strength of concrete cubes, helps to ensure that the concrete used in construction projects can withstand any external pressure as well as enhancing the overall safety of the projects.