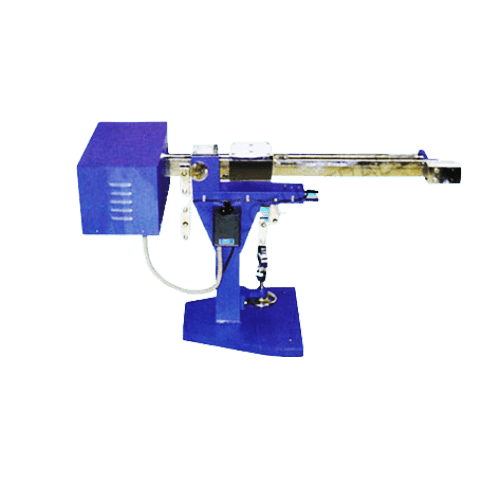

Tensile Strength Tester Electrically Operated

Precision in strength testing with electrical capabilities.

Tensile Strength Tester Electrically Operated

- High Quality Materials

- Compliance With Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Capacity | 900 kgs |

Power Mode | Ac |

Voltage | 230 V |

Accuracy | 0.5kg |

Information About Tensile Strength Tester Electrically Operated

Tensile strength is a crucial determinant of endurance or robustness of substances, such as cement to concrete. The tensile strength tester is used in the field of material testing where it examines tensile characteristics of different substances. By applying controlled forces, this sophisticated equipment accurately measures the breaking point and tensile capabilities of various materials.

Understanding the electrically operated tensile strength tester:

A high-tech tensile strength tester, also called electrically operated tensile strength tester, is a testing machine meant to provide the maximum tensile load that the materials can carry without destroying or deforming until rupture. The modern equipment uses electrically driven mechanisms to provide a measured force on the test material for accurate measurements of its tensile strength and elongation abilities. Integrating state of the art technologist this tensile strength tester will allow for uniformity in determining various properties and performance of materials under test using a reliable assessment procedure.

Key specifications

This brilliantly designed machine comes with an AC electrical motor with max voltage of 230v. this machine can produce a tensile force of 900kgs which enables extreme testing of the material. Its high strength forcing capabilities empowers the machine to achieve high accuracy with accuracy rate of 0.5kg.

Testing procedure:

Testing a test sample is conducted by placing it in the grip of an electro-mechanical tensile strength tester and pressing start button on the digital control panel. The equipment places a consistent pulling/compressing power on the sample until it is completely broken apart while also recording the corresponding stretch or distortion. Testing process offers data that aid in determining of tensile strength, ultimate tensile strength as well as the yield of the material revealing their mechanical characteristics for diverse pressure circumstances.

Importance of material testing:

It is worth stating that tensile strength testers are essential in the field of material testing since they enable us to obtain accurate information about the tension bearing capabilities of diverse materials such as cement and concrete. This modern equipment will help manufacturers, researchers and quality control teams conduct standardized tensile strength tests to ensure that the materials have required industrial standards and regulation parameters. The information generated by a tensile stress tester run with electricity helps in the adjustment of raw materials as well as manufacturing procedures with an intention to produce durable products for several industrial fields.

Advantages of electrically operated tensile strength testing:

An improvement in the accuracy in tensile strength testing with electrical operation enhances efficiency and reduces time spent on paperwork. Automating the testing process eliminates human error and standardizes testing parameters for consistent outcomes that can be reproduced. In addition, the ability to monitor real-time data provides the opportunity for users to make proper choices regarding material selection, product design, and manufacturing processes which contributes towards better products’ qualities and improved performances.

Usage in construction industry:

Electrical tensile strength tester is widely used in fabrication, construction, automobiles, aeronautics, and R&D among others. Professionals can decide on suitability of material, good product layout and maximize the toughness level to develop reliable durables for use in various sectors of industry and commerce using the technique in the evaluation of the tensile behaviour of different materials.

choosing to invest in a tensile strength tester supplied by Lotus Traders guarantees good quality and dependability. Lotus Traders remains firm in their promise to offer modern tools and top-notch client support, making them an authority figure in the market. Using advanced technology, firms choose electrically operated tensile strength testers because they guarantee precise results when testing of materials’ endurance is involved. With this, rest is assured that the lotus traders are committed into innovation and excellence such that this testing process can be flawless including these durable and long-lasting materials. Lotus Traders is an established supplier known for sophisticated systems and full support packages that will enable industrial players to adhere to high specifications in materials quality and performance.

Frequently Asked Questions

The tensile strength of cement can be determined from three types of tests:

- Direct pull test.

- Rupture test.

- Splitting tensile strength.

The cement tensile testing machine is primarily used to determine the tensile strength of cement samples. It is also used to measure the flexure strength of the sample.

There are majorly 2 tests performed for testing tensile strength of concrete such as:

- Flexure test: it tests how much motion the concrete can bear before it breaks.

- Direct tension test: it measures how much tension the concrete can bear before deforming.

- Splitting test: this test measures the splitting point of the concrete.

A tensile strength tester works by placing the sample into the pair of grips, further the machine applies increasing tensile force upon the sample until the sample breaks or rupture. This test measures the breaking point of the material and determines the best usage of the material.

Due to the rigid nature of concrete structures, they are highly cautious to cracking and splitting under different conditions and loads. This is the reason tensile strength testing of cement or concrete is important.

As per ISI:456-2000, section – 6.2.2, the tensile strength of the concrete is 0.7 times the square root of the characteristic compressive strength of the concrete cube. For example, M20 grade concrete has a compressive strength has a compressive strength of 20 N/mm2 and its tensile strength must be 2-3 N/mm2. By this way we can calculate the compressive and tensile strength of any concrete.

Tensile strength can be defined as the maximum stress that a material can bear before breaking when it is stretched or pulled.

The unit of tensile strength in international system are called:

- Pascals, (Pa)

- Megapascal, (MPa)

- Gigapascal, (GPa)

Tensile strength can be upgraded by following ways:

- Use hotter mould temperature.

- Use high injection speed.

- Avoid high melt temperature.

- Optimum injection pressure.