Cube Testing Machine Manual

- High Quality Materials

- Compliance With Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

Introduction About Cube Testing Machine Manual:

What is Manual Cube Testing machine?

Concrete cube compressive strength is determined using a manual cube testing machine. To test the quality of concrete, building laboratories frequently employ this straightforward yet efficient device.

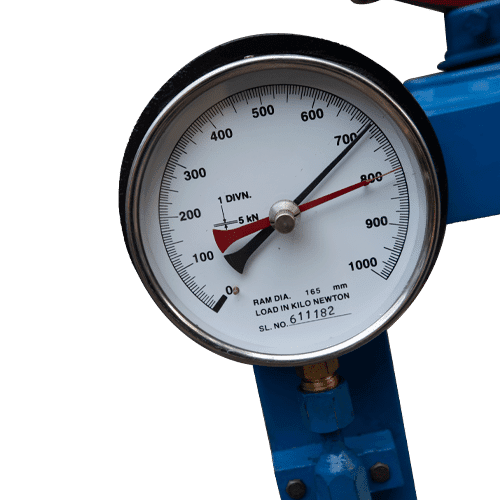

The parts of a manual cube testing machine usually include a dial gauge, a pressure gauge, a hydraulic jack and a loading frame. The machines loading platens are positioned between the concrete cube and the cube is compressed using a hydraulic jack. The applied load is measured with a pressure gauge and the cubes deformation is measured with a dial gauge.

The applied force is divided by the cubes cross sectional area to determine the concrete cubes compressive strength. Concretes compressive strength plays a crucial role in determining how well it can support loads.

Handheld cube testing devices are reasonably priced and simple to use. They are not, however, as precise as automated cube testing devices. More accurate findings are obtained from automated cube testing equipment that monitor the applied load and deformation of the cube using displacement sensors and electronic load cells.

Construction laboratories still employ a lot of manual cube testing machines these days, especially in developing nations where automated cube testing machines could be too costly or difficult to operate.

Key features of manual cube testing

Several salient features associated with manual cube testing are as follows:

· Simple and economical: Manual cube testing devices are reasonably priced and simple to use. For labs on a tight budget, this makes them a viable choice.

· Manual cube testing apparatuses are easily transported to various sites due to their portability. Onsite concrete testing may benefit from this.

· Requires little maintenance: Manual cube testing devices are a dependable choice for labs with constrained resources because they require very less upkeep.

· Adaptable: A wide range of concrete mixes and cube sizes can be tested using manual cube testing equipment. For laboratories that analyze a variety of concrete samples which makes them a good choice.

Benefits of manual cube testing

The following are the benefits of using manual cube testing machine.

· Economicality: Manual Cube Testing apparatuses are a suitable choice for labs with tight budgets because they are reasonably priced to buy and operate.

· The ease of use: Manual Cube Testing equipment is easy to use and doesnot require any specific training.

· Flexible use: A range of different concrete mixes and cube sizes can be tested using Manual Cube Testing equipment.

· Being portable: Manual Cube Testing apparatuses are usually easily transported to various sites due to their Portability.

· Integrity: The compressive strength of concrete cubes has long been tested using Manual Cube Testing devices which have been in use for many years.

Apart from these advantages, there are several special benefits that manual cube testing has over automated cube testing techniques. Operators can have greater control over the testing process, for instance, while using manual cube testing. When testing uncommon concrete mixes or cube sizes, this can be useful. Furthermore, imperfections in concrete cubes that might go undetected by automated techniques might be found via hand cube testing.

In summary, evaluating the compressive strength of concrete cubes by hand is a dependable and economical technique. It is an especially smart choice for labs with tight finances or resources.

In particular, the following instances demonstrate the advantages of manual cube testing:

· Concrete can be tested onsite by hand using cube testing. For quality assurance or to look into concrete failures, this can be helpful.

· For small batches of concrete, manual cube testing might be employed. Testing speciality concrete mixtures or doing research and development can both benefit from this.

· Concrete cubes of unique sizes or shapes can be tested manually. Concrete testing for unconventional applications may benefit from this.

Uses of manual cube testing

· Concrete cubes compressive strength is determined by hand cube testing. The most significant characteristic of concrete is its compressive strength which dictates how much weight it can support. There are several uses for manual cube testing such as:

· Control of quality: Concrete is tested manually using cubes to make sure it satisfies the required minimum compressive strength. Ensuring the safety and longevity of concrete constructions is contingent upon this.

· Research and development: To create novel concrete mixes and assess how well various concrete additives work, manual cube testing is utilized.

· Concrete failure investigations: The causes of concrete failures are looked into via manual cube testing. This can be useful in creating remedial strategies and averting more mistakes.

· Onsite testing: Concrete can be tested onsite using manual cube testing. Investigating concrete failures or quality control purposes may benefit from this.

· Here are some particular instances/examples of the uses of manual cube testing:

· Testing concrete for bridges: It is critical to make sure the concrete satisfies the required standards for compressive strength since concrete bridges need to be able to support large loads. The compressive strength of concrete used in bridge building is confirmed by hand cube testing.

· Testing concrete for tall buildings: To withstand the weight of the structure as well as the effects of wind and earthquakes, tall buildings also need high strength concrete. The compressive strength of concrete used in building tall buildings is confirmed by manual cube testing.

· Testing concrete for dams: It is crucial to make sure that the concrete used in the construction of dams satisfies the prescribed compressive strength standards since dams need to be able to support the massive weight of water. The compressive strength of concrete used in dam construction is confirmed by manual cube testing.

· Testing concrete for airport runways: It is critical to make sure that the concrete used in runway construction satisfies the required standards for compressive strength since airport runways need to be able to support the enormous weights of aircraft. The compressive strength of the concrete used to build runways is checked manually using cube testing.

· Testing concrete for pavements: It is critical to make sure that the concrete used in pavement construction satisfies the required standards for compressive strength since concrete pavements need to be resilient enough to endure traffic wear and strain. The compressive strength of concrete used in pavement construction is confirmed by manual cube testing.

How manual cube testing works?

While manual cube testing is a very simple procedure, correct execution of the stages is necessary to obtain reliable results. Below is a summary of the manual cube testing process:

Prepare the concrete cubes. Concrete cubes need to have a smooth, square exterior. The accuracy of the test results could be jeopardized by any cracks or gaps on the cubes surface.

Place the concrete cube inside the testing device. The cube needs to be centered inside the machine and in contact with the loading platens on all four corners.

Apply force to the cube. The weight should be applied steadily until the cube fails.

Take note of the largest load. The maximum load is equal to the compressive strength of the concrete cube.

Further information on each step of the manual cube testing process is provided below:

1. Setting up the concrete blocks:

· The concrete cubes must cure for at least 28 days in a wet setting before testing.

· The cube tops should have a small layer of gypsum or sulfur added to them to provide a smooth surface for loading.

· The cubes must be stored in a dry and cold place until testing.

· Placing the concrete cube into the testing device:

· When inserting the cube into the testing instrument, its capped surface need to be facing upwards.

· The cube should be in the center of the machine and should make contact with the loading platens on all four corners.

2. Subjecting the cube to a load:

· It is important that the load be applied to the cube steadily. A recommended loading rate is between 0.2 and 0.4 MPa/s.

· Until the cube breaks, the load should be applied continuously.

· Failure occurs when there is a sudden drop in load or when the cube breaks into two or more pieces.

3. Noting the maximum load that could exist:

· The maximum load is equal to the compressive strength of the concrete cube.

· The maximum load must be recorded to the nearest 0.1 MPa.

· The concrete cubes compressive strength can be calculated by dividing the greatest load by the cubes cross sectional area once the manual cube testing process is complete.

Conclusion

Concrete strength is measured manually using cubes that are standardized and placed in layers with compacting in between. The cubes are usually 150 mm or 100 mm on each side. The cured cubes are demolded and put through a compressive strength test after curing for a predetermined amount of time (such as seven or twenty eight days).

This entails putting each one in a compression testing device one at a time, recording the maximum load and progressively applying load until failure. Next, compute the compressive strength by dividing the greatest load by the cubes cross sectional area.

This technique checks to see if the concrete satisfies required strength standards ensuring quality control in the building industry. For dependable results, precise preparation, curing, testing and computation are essential. These steps let engineers and construction experts decide whether the concrete mix is appropriate for the intended structural uses.

- DESCRIPTION

FEATURE | SPECIFICATION |

Display Type | Analog |

Material | Mild Steel |

Frequency | 50 Hz |

Color | Blue |

Automation Grade | Manual |

Capacity | 1000 kn |

Concrete Mixer Machine With Lift

Manual 4 Cavity Brick Machine

Egg Laying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator