Home > Rock Testing Equipment

ROCK TESTING EQUIPMENT

Rock testing equipment:

Essential tool for testing the quality of rock.

Rock testing equipment is an important tool used in geology, civil engineering, and material science to determine the physical and mechanical properties and strength of rocks. These machines enable rock samples to control stress and deformation conditions, which allows researchers and engineers to collect important data for a variety of applications. This equipment applies axial force on rock samples, where compressive strength, tensile strength, elasticity, and deformation of rock is calculated. The data collected during this process helps in geological studies, designing of structural projects like tunnels and dams and assessment of rock stability in mining and quarrying activities. Thus, rock testing equipment plays an important role, ensuring the safety and durability of infrastructure built with rocks.

Significance of rock testing equipment:

Rock testing equipment are significant for various reasons –

These machines allow scientists and engineers to characterise the strength, durability and deformation of rock, which helps in the selection of best materials for construction projects.

Such equipment analyses rock specimens to help understand geological processes such as weathering, erosion, and sedimentation.

Rock testing tools also provide an overview to scientific research by giving information about the earth’s crust and geologic structures.

Principle of rock testing equipment:

Rock testing machine is essential for determining the properties and other factors of rocks in various engineering and geological fields. They deal with the following principles: –

Stress and Strain Analysis: Rock testing machines gives the response of rock to applied stress and strain. These tools apply steer force on rock samples and record their deformation to determine their different mechanical properties.

Sample Preparation: In order to get proper results, preparation of rock samples with utmost carefulness is important. This equipment must provide tools to precisely cut, shape, and size samples to meet test standards.

Load Application: Such machines apply forces to rock specimens with the help of hydraulic systems or through other mechanics to examine strength and other physical factors of rock.

Data Acquisition: Rock testing equipment are well equipped with data acquisition systems which records various data of the different tests carried out during the processing. This, ensuring precision and authenticity.

Compression and Tension Testing:

These tests are performed on the rock sample to evaluate rock’s compressive or tensile strength which gives the structural properties of the rock.

Hydraulic Fracturing: There are rock tools designed for hydraulic fracturing tests. This includes creating fractures in a rock sample to understand its behaviour in engineering and geothermal applications.

Environmental Control: Maintaining environmental conditions, including temperature and humidity, is important to get precise results during testing.

Data Analysis: Data analysis tools present in rock testing mechanisms

gives different results such as stress-strain curves, failure modes, and other factors related to engineering or geological aspects.

Safety: Proper precautions should be taken while using such equipment. One should undergo appropriate training in order to operate rock testing equipment as they employ great forces.

Importance of rock testing equipment:

Safety control: The tools available in rock testing equipment helps to determine the rock’s stability used in construction, mining, and geotechnical engineering, which ensure safety for workers.

Material Characterization: Rock testing equipment given an overview of the physical properties of rocks, such as density, compressive strength, and elasticity, which helps in material selection and designing.

Quality Control: Rock testing equipment ensures the quality of rock materials, which can hinder day-to-day project activities.

Research and Development: These tools help researchers to study rock behaviour under different conditions, leading to advances in geotechnology and civil engineering.

Environmental Impact Assessment: Determining how rocks respond to stress and weather helps to understand and mitigate environmental disasters such as landslides.

Products and services provided by lotus traders in rock testing field:

Lotus Traders is famous for its quality standard and excels in providing high quality products to the customers. Lotus Traders is the one-stop destination for all your construction needs and equipment.

Following are some commonly used rocks testing equipment supplied by Lotus traders:

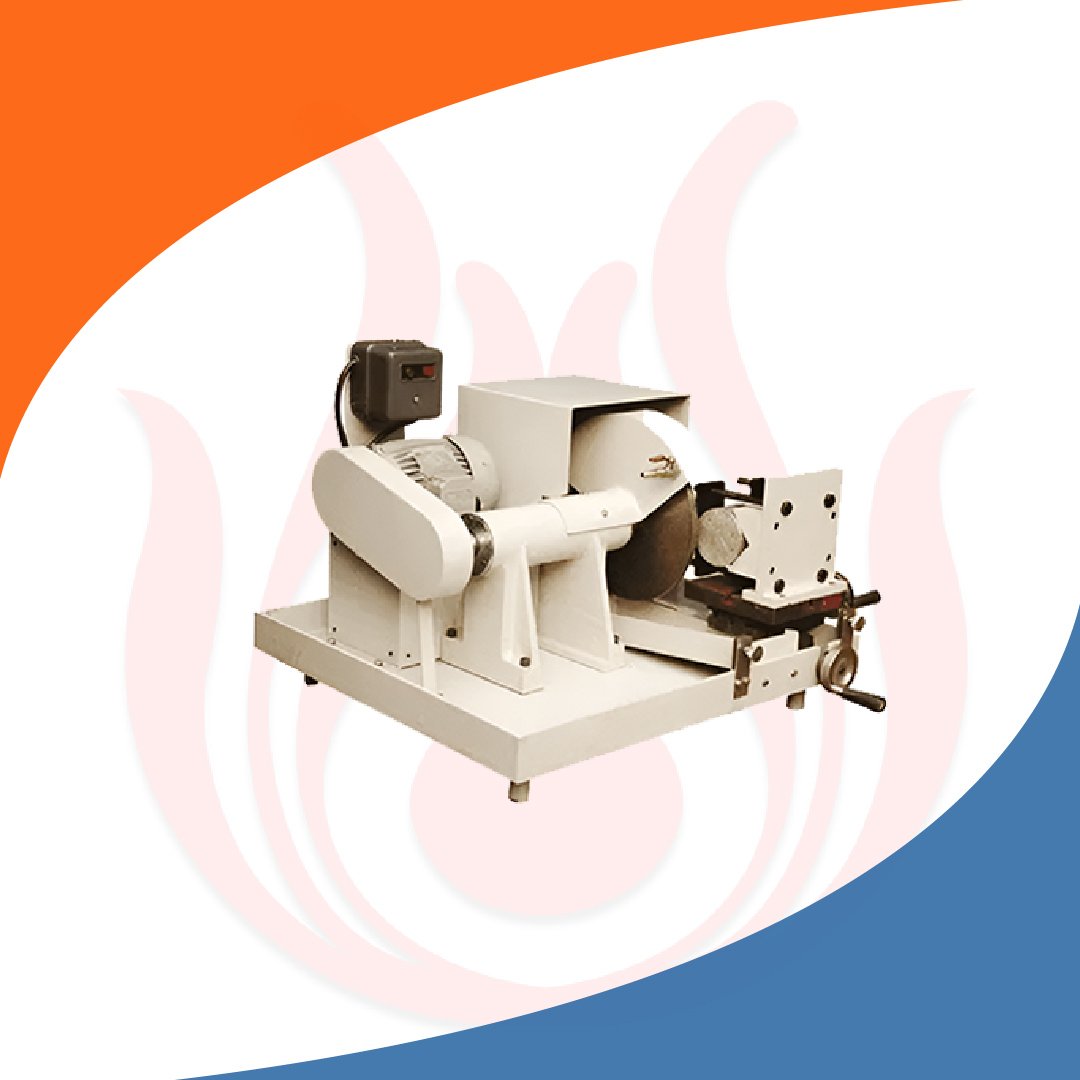

Automatic Grinding Machine: Automatic grinding machines are an essential tool required in rock testing laboratories, which helps in preparing geological samples for different analysis purposes. It has a dimension of 730*1080*1510 mm, weight approx. 280kg and operates on a power of 1850w.

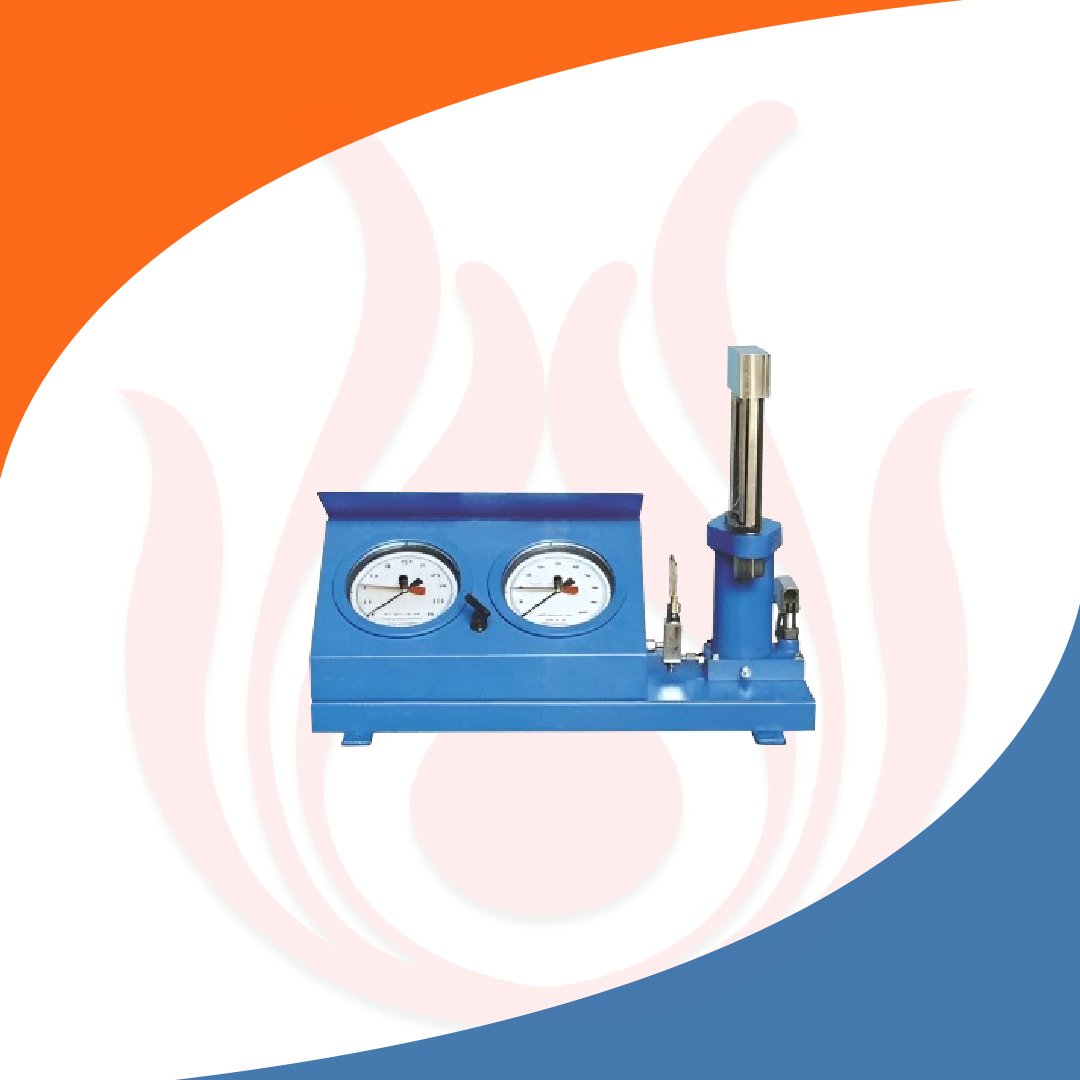

Brazilian Test Apparatus: Brazilian Test Apparatus are an important tool in rock testing which helps in determining the tensile strength of the rock material. It has a plate diameter of 50mm and pressure gauge capacity of 0-100 kn × 1 kn.

Core Cutting Grinding Machine: Core cutting and grinding machines are used in rock testing to prepare geological specimens. It helps in cutting rock cores and then grinding them to specific dimensions for different analysis. Stainless Steel is used as a material of construction.

Digital Point Load Test: Digital Point Load Test is a method for determining rock’s strength properties. This involves applying load to a rock sample and then evaluating the applied load and resulting deformation. It has a load range of 0-60 kn, digital display of 2×16 characters, resolution of 32.000 div and an accuracy of ± 1%.

Hoek Triaxial: The Hoek triaxial equipment is an essential tool in rock testing which is used to measure the different properties of rock material such as strength and deformation. Stainless steel is used as a construction material.

Load Frame for Universal Compression Test: This test is an important test in rock testing, which is achieved by applying controlled axial loads on rock samples, thus assessing their compressive strength and deformation properties. It has a horizontal clearance and vertical clearance of 300 mm and 750 mm respectively, maximum platen diameter of 198mm, maximum platen travel of 100 mm and specimen diameter should be 38mm to 100mm.

Point Load Index: Point Load Index test is a method used in geotechnology and rock engineering to measure the strength of rock samples.

Polishing and Lapping: Polishing and lapping equipment is an important tool in rock testing used to assess various properties and characteristics of rock samples. It has a top diameter of 20cm, 1 HP Single Phase A.C. motor, motor capacity of 230 V and 450/500 rpm motor driven unit.

Motorized Core Cutting / Core Drilling Machine: These machines consist of a motor-driven drill bit which rotates and cuts the rock. The sample can is then studied to determine different mechanical properties of the rock sample. It requires a voltage of 220v/50hz, power input of 2800w, no load speed 840 rpm and 25mm dia – 150mm dia bit capacity.

Rock Bolt Pull Out: Rock bolt pull-out is a testing process which is used to determine the performance capacity of rock bolts that are used in mining, tunnelling, and civil engineering projects.

Slake Durability: Slack durability refers to the rock’s ability to resist decomposition when exposed to cycles of wetting and drying. It has a mesh diameter of 140mm, 100 mm length and 20 R.P.M motor capacity.

Asphalt & Concrete Floor Saw: Asphalt and concrete floor saws are used in rock testing to make cuts and prepare samples for various geological studies. It consists of a diamond blade 350 to 500 mm in size that is used to cut the rock material.

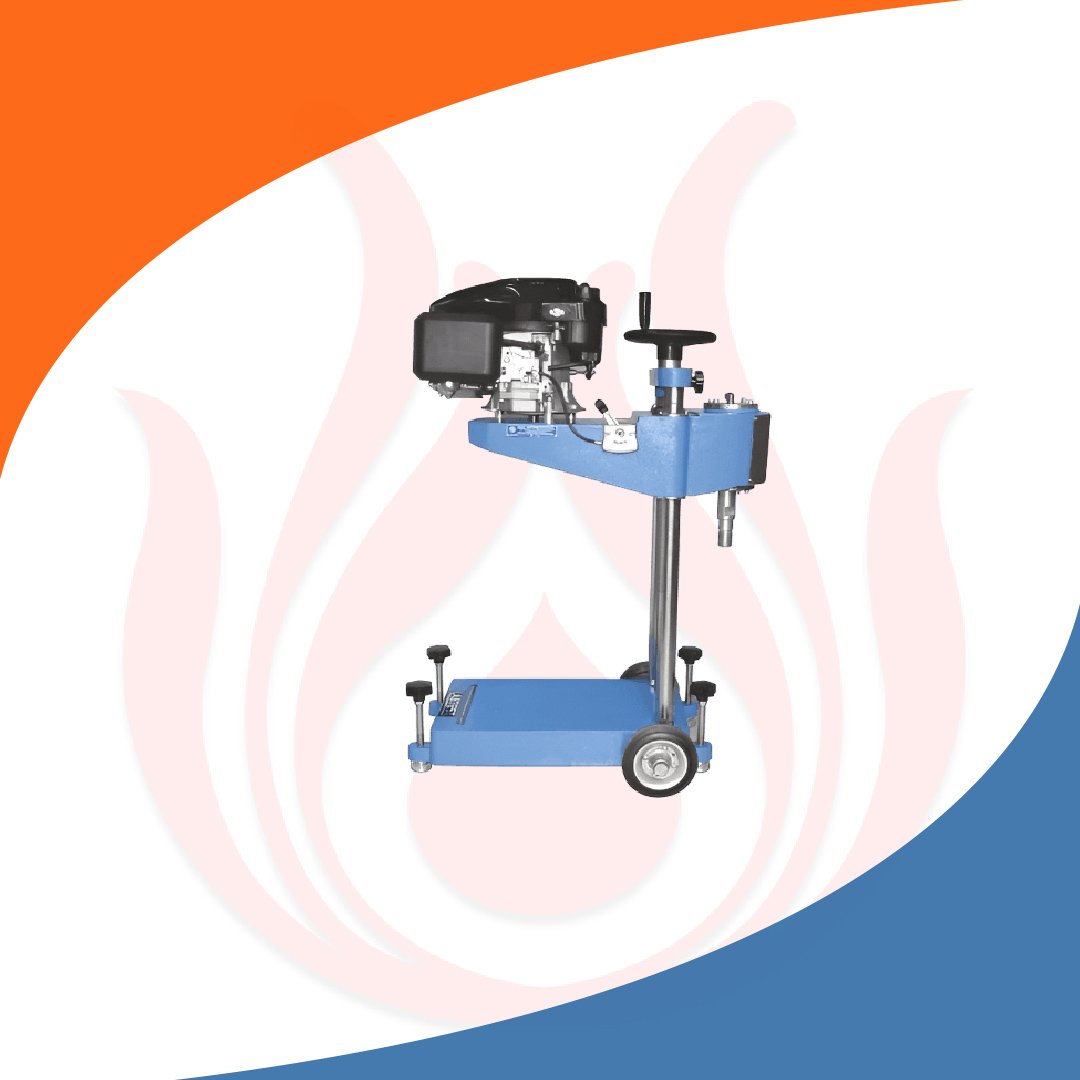

Portable Core Cutting Drilling Machine Petrol Driven: A portable core cutting drilling machine is used in rock testing. These machines extract cylindrical rock core samples for geological studies. It weighs approx. 100 kg, power petrol engine 6.5 HP and core cut diameter 200 mm.

Core Cutting/Core Drilling Machine Petrol: These machines are petrol driven that provides power to drill through rock samples to get core samples for analysis. It has height of 1300 mm, base of 625*900mm, Head travel on rack (500mm), drill speed 900 R.P.M. for soft samples and 350 R.P.M. for hard Samples, water swivel is already built-in and engine (Petrol 190 cc).

Tunnels, bridges, and many other infrastructures are an essential part for Indian civilization. Many dreams travel through those tunnels and bridges, the dream of make in India. So in order to maintain these infrastructures it is important to purchase rock testing equipment from reputed manufacturers and suppliers.

Choosing Lotus Traders as your supplier for rock testing equipment will give you many advantages, including quality products, reliability and expertise. Lotus Traders never compromises with any of its products and thus supplies top class equipment ensuring safety and various demands in the construction and engineering sectors.

Frequently Asked Questions

The different equipment used in rock testing are:

Automatic Grinding Machine, Brazilian Test Apparatus, Core Cutting Grinding Machine, Digital Point Load Test, Hoek Triaxial, Load Frame for Universal Compression Test, Point, Load Index, Polishing and Lapping, Motorized Core Cutting / Core Drilling Machine

Rock Bolt Pull Out, Slake Durability, Asphalt & Concrete Floor Saw, Portable Core Cutting Drilling Machine Petrol Driven, Core Cutting/Core Drilling Machine Petrol and many more.

The main features of rock testing equipment are:

They are versatile in nature as they can perform various tests including tensile strength, uniaxial and triaxial compression and many more. Rock testing equipment provides results with accuracy and precision. It has a modern data acquisition system. They can also simulate extreme conditions such as high temperature and pressure which are important for geological studies.

Safety precautions that should be considered are –

The operator must be properly trained and should be familiar with the features and functionality of the equipment. Wearing of safety glasses, gloves and other protective wears are important. Regular inspection of such equipment is mandatory.

The price ranges from 10000 – 200000 INR approximately which is variable as per the customer requirements.

Rock test is done by performing various assessment methods such as: point load test, Brazilian test, strict rules and regulations are being followed for assessment to conclude the final result such as tensile strength, rock quality and its workability.

Rock classification is the procedure to classify different kinds of rocks into categories such as: igneous, sedimentary, and metamorphic.

Characteristics of rock are:

Colour, streak, hardness, cleavage, fracture, and lustre.

Most rock maintains their density between 2.6 and 2.7 g/cc.

Rocks are made up of different minerals, broken pieces of crystals and shells of ancient animals.

A rock with oil has unit weight of 29.3 kN/m3, and a dry rock has a unit weight of 26.4 kN/m3.

Recommend Products

One Bag Concrete Mixer Machine

Manual 4 Cavity Brick Machine

Egg Lying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator