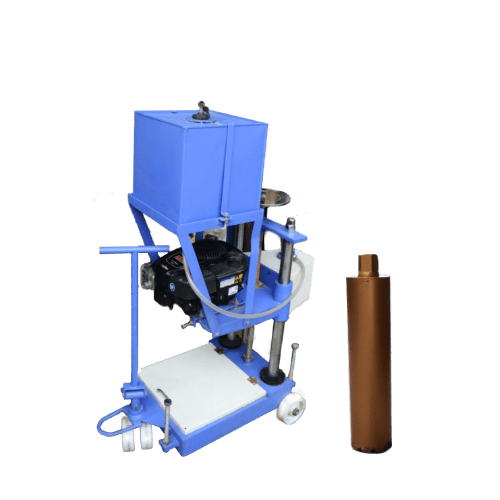

Core Cutting/Core Drilling Machine Petrol

- High Quality Materials

- Compliance With Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Height | 1300mm |

Base | 625*900mm |

Head travel on rack | 500mm |

Drill Speed | 900 R.P.M. for soft samples and 350 R.P.M. for hard Samples |

Water Swivel | Built in the machine |

Engine | Petrol 190 cc |

Information About Core Cutting/Core Drilling Machine Petrol:

Core cutting (or core drilling) machines are essential tools in the construction, mining, and civil engineering industries, used to cut precise cylindrical holes in various hard materials such as concrete, stone, asphalt, and rock. These machines are versatile and powerful, designed to create clean, round openings for a range of applications, from installing pipes and cables to extracting core samples for analysis.

Overview of Core Cutting/Core Drilling Machines

Key Features:

Power Source: Machines are typically powered by electricity, petrol, diesel, or hydraulics, making them suitable for different work environments, including remote locations without access to electricity.

Diamond Core Bits: The primary cutting tool is a diamond-tipped bit, known for its ability to cut through tough materials efficiently while maintaining durability.

Adjustable Drilling Depth and Diameter: Machines allow for variable drilling depths and diameters, ranging from small holes (20 mm) to large openings (up to 600 mm or more), depending on the bit size.

Water Cooling System: Many models feature a water feed system to cool the drill bit, reducing heat buildup, extending the bit’s lifespan, and controlling dust during drilling.

Portable and Mounted Options: Available in portable handheld versions for small-scale tasks and larger rig-mounted versions for heavy-duty applications. Some advanced models are fixed on rails or stands for added stability and precision.

Safety Features: Includes overload protection, emergency shut-off switches, anti-kickback systems, and vibration reduction handles to enhance operator safety and control.

Types of Core Cutting/Core Drilling Machines:

Handheld Core Drills:

- Use: Ideal for smaller holes and less demanding tasks such as plumbing and electrical installations.

- Power: Typically electric or battery-powered.

- Portability: Lightweight and easy to maneuver, but requires a steady hand for accuracy.

Rig-Mounted Core Drills:

- Use: Suitable for large diameter drilling and deep cuts, commonly used in construction, demolition, and road maintenance.

- Power: Available in electric, hydraulic, and petrol versions.

- Stability: Mounted on a stand or frame, which is often anchored to the ground or the work surface for precision.

Hydraulic Core Drills:

- Use: Designed for heavy-duty applications, offering high power and torque for deep and large diameter drilling.

- Power: Uses hydraulic power, which provides better control and less vibration.

- Advantages: Ideal for underwater drilling and extreme conditions where electrical safety is a concern.

Wall-Mounted Core Drills:

- Use: Primarily used for drilling precise, large holes in walls, floors, and ceilings in construction projects.

- Power: Electric or hydraulic power, often combined with advanced controls for depth and angle adjustments.

Applications:

- Construction and Renovation: Creating holes for plumbing, HVAC installations, and structural modifications.

- Road and Bridge Work: Drilling holes in pavement for maintenance, installation of road barriers, and expansion joints.

- Demolition: Controlled drilling for breaking down structures without damaging the surrounding areas.

- Geological Sampling: Extracting cores of soil, rock, or concrete for analysis in environmental and geotechnical studies.

- Utilities Installation: Drilling for the installation of water, gas, and electrical lines.

Technical Specifications:

- Drill Speed: Adjustable RPM settings to match the material being drilled, usually ranging from 200 to 3000 RPM.

- Power Output: Electric models range from 1.5 to 5 kW, while petrol and hydraulic models offer higher power outputs for demanding tasks.

- Maximum Drilling Diameter: Typically from 20 mm to 600 mm, with extensions available for larger needs.

- Maximum Drilling Depth: Can range from a few centimeters to over a meter, depending on the machine and drill bit length.

Advantages:

- Precision: Capable of creating clean, accurate holes without damaging the surrounding material.

- Versatility: Handles a wide range of materials and applications, from light-duty to heavy industrial tasks.

- Efficiency: Faster and more reliable than traditional drilling methods, reducing overall project time.

- Low Vibration and Noise: Particularly hydraulic models, which offer quieter operation with reduced vibrations.

Maintenance Tips:

- Regular Inspection: Check for wear on drill bits and replace them when necessary to maintain cutting efficiency.

- Lubrication: Keep moving parts well-lubricated to avoid overheating and damage.

- Water System Maintenance: Ensure the water cooling system is functional to prevent overheating of the core bit.

- Clean After Use: Remove dust and debris from the machine and bit after each use to prevent clogging and corrosion.

Safety Precautions:

- Wear Protective Gear: Use safety goggles, ear protection, gloves, and dust masks to protect against debris and noise.

- Stabilize the Machine: Ensure the machine is securely anchored to prevent movement during drilling.

- Avoid Overloading: Do not apply excessive force; let the machine’s power and bit do the work to avoid accidents.

- Proper Training: Operators should be trained in handling core drills safely, understanding control settings, and emergency procedures.

Concrete Mixer Machine With Lift

Manual 4 Cavity Brick Machine

Egg Laying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator