Home > Steel Testing Equipment

STEEL TESTING EQUIPMENT

Steel testing equipment: Essential tool for measuring the quality of steel.

Steel testing equipment are a range of different instruments and equipment which is used to evaluate the numerous properties and quality of steel materials. These instruments are essential in several industries, including construction, manufacturing, and engineering. Common equipment such as universal testing machines, tensile testing machines, hardness testers and impact testers, gives the quality profile for a steel material. This equipment’s are of great importance for manufacturers and construction units to rectify that the steel materials are of good quality and whether it is meeting the quality standards. Hence, ensuring the safety and durability of products that are made out of steel materials.

Significance of steel testing equipment in construction, engineering and manufacturing units:

Steel testing equipment are an important tools in construction for many reasons.

- It guarantees the quality and safety of structures by analysing the strength and longevity of steel materials.

- It provides assistance in quality control during the manufacturing and fabrication processes.

- Manufacturer’s uses these equipment’s to rectify the properties of raw materials and finished steel products, ensuring consistency in material quality.

- Steel testing equipment also aids in research and development, which gives engineers and exposure to inventive steel productions and designs.

Usage of steel testing equipment:

Steel testing machines are used to assure the quality and reliability of steel products in various industries. These technicalized instruments are designed to evaluate the various properties of steel, providing the overview of the material to manufacturers and engineers.

Importance of Steel testing:

Steel testing are important for numerous reasons. They are –

- Safety Concerns: The sturdiness of steel is very crucial for the safety of buildings, bridges, and other infrastructure. Compromising with steel quality can can lead to uncertain mishaps.

- Quality Control: Steel testing provides assurance to the manufacturers that the steel material is of good quality and has gone through all the standards.

- Durability: Steel testing helps determine how resistant the material is to corrosives and all other components that can affect its longevity.

- Compliance: There are various regulations and standards for the use of steel in many industries. Testing assures conformity with these regulations.

Necessary test done with the help of steel testing equipment:

- Tensile Testing: This test analyses the steel’s tensile strength, yield strength, and elongation properties.

- Hardness Testing: Different hardness tests like Rockwell, Brinell, or Vickers measure the steel’s hardness and other material properties by penetrating it.

- Impact Testing: The test evaluates the resistance of the steel to instant loads and impact force, using an instrument such as a Charpy impact tester.

- Fatigue Testing: Fatigue of steel is determined by applying loads to a material and observe it’s response until it fractures.

- Microstructural Analysis: Metallography tools are used to measure the microstructure of steel, including grain size, inclusions, and phase distribution.

Products and services provided by lotus traders in aggregate testing field:

Products and services provided by lotus traders in aggregate testing field:

Lotus traders is widely known for its quality standard and top quality products. Lotus traders is the one stop destination for all your construction requirements and equipment.

Following are some commonly used steel testing equipment supplied by Lotus traders :

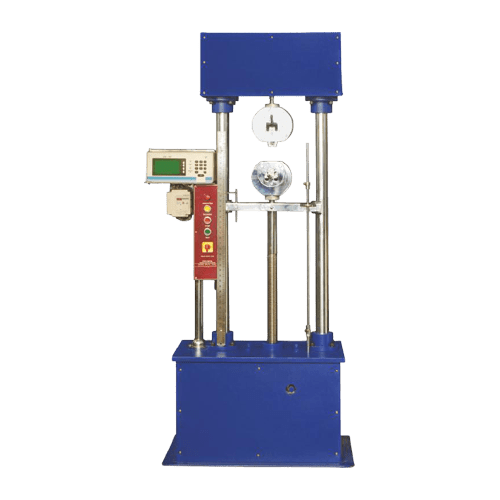

Tensile Testing machines : This testing equipment are used to measure the tensile strength, yield strength and elongation of steels until they fracture.

Objective – The main objective of tensile testing machines is to determine the various mechanical properties of materials, and their reaction to tensile forces.

Rockwell Hardness Tester: This helps to determine the hardness of steel, by penetrating the object to determine how hard or soft the material is.

Objective – The main objective of a Rockwell Hardness Tester is to evaluate the hardness of a steel material. An important aspect for quality control and material selection in various industries.

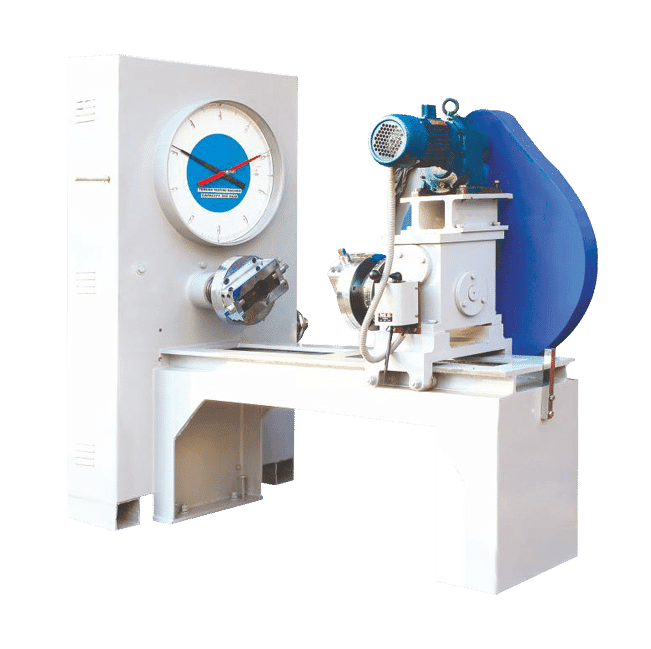

Torsion Testing Machine : It smear torque to a object and estimate its retort, which assess the strength and deformation characteristics of the object.

Objective – The main objective of a torsion testing machine is to evaluate the mechanical properties of a steel material, particularly its resistance to torsional deformation.

Hydraulic Computerized UTM: It is a computer based mechanical testing machine which is used to determine the quality of steel and other materials.

Objective – The main objective of hydraulic computerized UTM is to precisely determine and analyze the material’s tensile, bending, and other mechanical properties.

Brinell Hardness Testers : This machine is used to test metals and alloys, which shows the object’s aversion to deformation.

Objective – The main objective of brinell hardness tester is to determine the hardness of a material by penetrating it with a known load to measure its resistance to deformation.

Charpy Impact Test Machine: This machine is used to estimate the toughness or resistance of objects.

Objective – The main objective of charpy impact tester is to measure a material react to a sudden impact, which is important for assessing the material’s applicability.

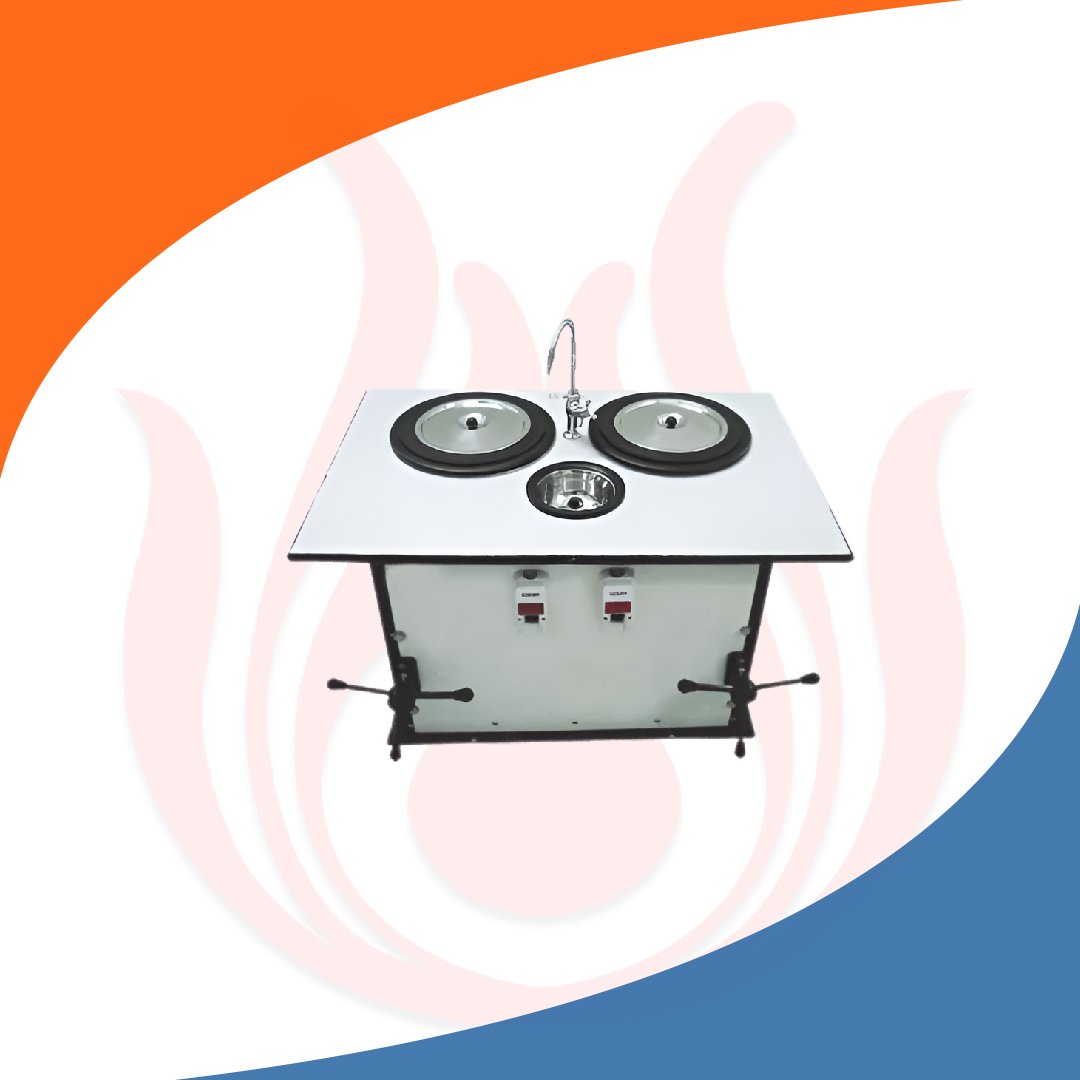

Double Disc Polishing Machine: This machine is used to crush and polish the surface of steel to assemble it for microscopic examination.

Objective – The main objective of double disc polishing machine is to precisely polish surfaces of various materials.

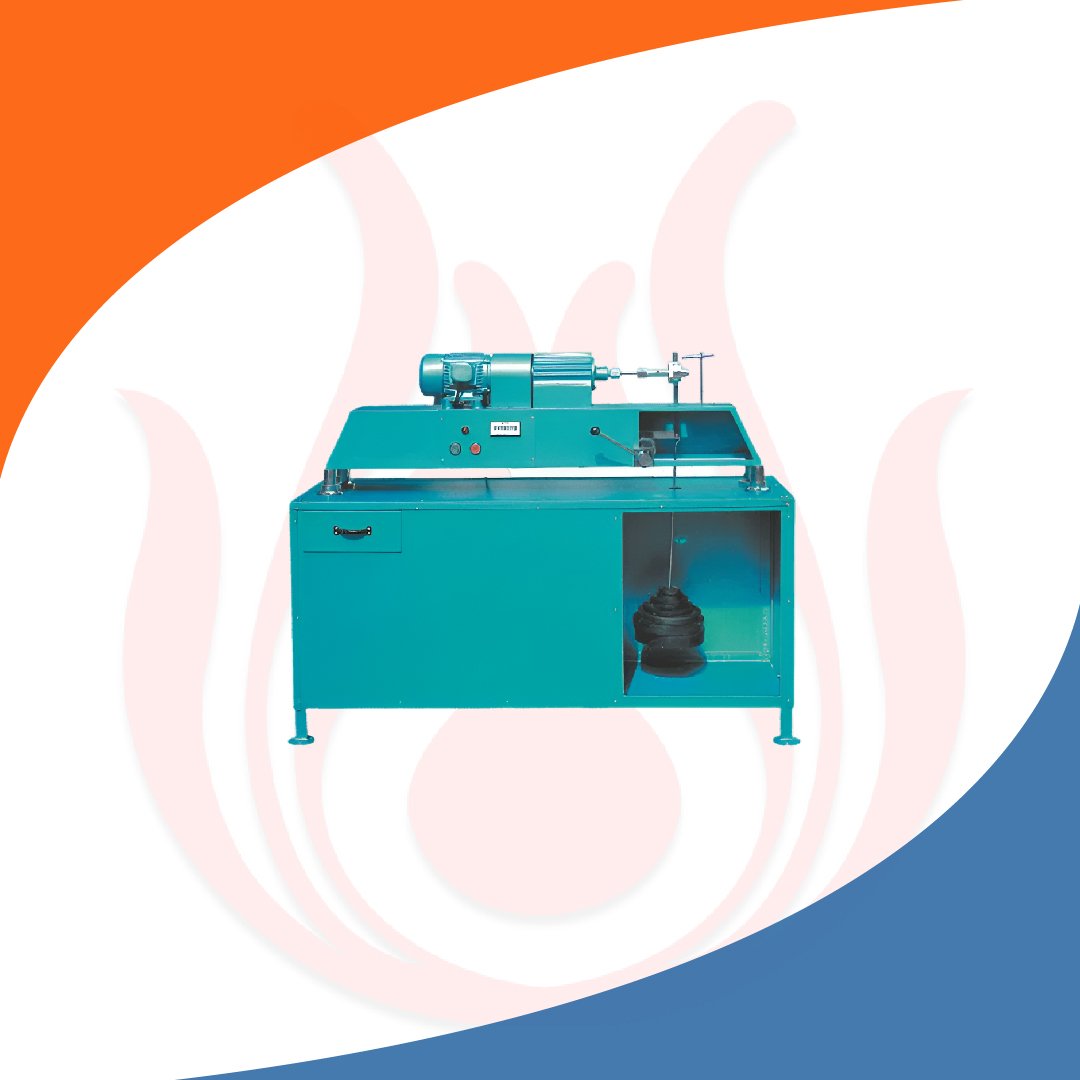

Fatigue Testing Machine: This machine is used to determine the longevity as well as mechanical properties of materials by applying mechanical stress to a object till it reaches specified number of cycles or ruptures.

Objective – The main objective of fatigue testing machine is to determine fragility or catastrophe of a material due to repeated use, thus ensuring quality standards and safety.

Specimen Mounting Press: This machine is used in materials science and metallurgy laboratories to prepare samples for microscopy or other analysis.

Objective – The main purpose of a specimen mounting press is to fix a metal object to a mounting material, which involves grinding, polishing and examining the sample under a microscope.

Frequently Asked Questions

Some different test done with steel testing equipment are mentioned below –

- Tensile Testing

- Hardness Testing

- Impact Testing

- Fatigue Testing

- Microstructural Analysis

The features of such equipments are –

- It has capability of testing steel’s mechanical properties, which includes tensile strength, hardness, and impact resistance.

- This tools help is getting accurate measurement, ensuring reliable results.

- They have a built-in safety mechanisms to protect operators as well as the equipment and many more.

Steel testing equipment is known to provide results with high precision and accuracy, when operated correctly. But the accuracy of a steel testing equipment generally depends on the type of test being run and the quality of the equipment

Safety precautions that should be considered are –

- The operator has to be properly trained and should be familiar with the features and functionality of the equipment.

- Wearing of safety glasses, gloves and other protective wears are important.

- Regular inspection of such equipment’s are of utmost importance.

The advantages of using steel testing equipments are –

- In terms of precision, these tools provides accurate measurements of various mechanical properties of steel, ensuring that the material is of good quality and has maintained all the required standards and specifications.

- Steel testing equipment ensures that the steel materials used in construction and in other units are of good quality, preventing any structural failures or mishap.

- Identification of any defects and fragility of a material in the early stages of a production process can help prevent reworking which can be time consuming and can cause loss of capital.

The price of steel testing equipment’s usually ranges from 10000-100000 (variable) as per the customer requirements.

Recommend Products

One Bag Concrete Mixer Machine

Manual 4 Cavity Brick Machine

Egg Lying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator