- Home

- Brick Making Machine

- interlocking brick making machine

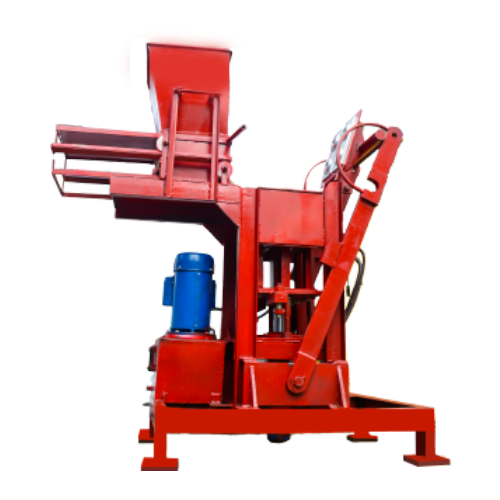

Single Cavity Interlocking Brick Making Machine

Single Cavity Interlocking Brick Making Machine

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

Concrete Mixers first came into existence in the 1900s having a simple drum-like structure

powered by steam engine has gone since major modifications till date with continuous

advancement in engineering, keeping up with the evolving needs in the construction sector.

Earlier the Concrete mixers were powered by steam engine, now the concrete mixers usually run

on Diesel but the base drum-shaped body remains the same.

Concrete is majorly used in the construction industry. Concrete is an aggregate of usually

stone or gravel, water and cement. Modern cement is a complex blend of finely ground minerals,

called “Portland”. The cement plays a major role as the binder to the aggregates whereas the

aggregates acts as the filler materials that give strength to concrete. Concrete is made by

combining the three ingredients in a Concrete mixer machine, the water is absorbed by the

cement, which then binds the aggregate together, creating concrete .

FEATURES | SPECIFICATION |

Capacity | 400 pcs / Day |

Power Required | Zero |

Usages | Manufacture Concrete/Clay Interlocking Block |

Process | Manual |

Block Size | 10 x 5 x 4 /5 Inch |

Cavity | Single |

What is Single Cavity Interlocking Brick Making Machine?

For producing interlocking bricks here comes an interlocking single cavity brick making machine that is a common piece of machinery that helps individuals and businesses to make bricks. It is made to make bricks that may interlock with one another to form a sturdy building without the use of mortar or cement.

The machine normally has a strong frame composed of steel or another long-lasting material. It gives the other elements the framework and support they need. The brick is created in a single cavity or mould on the machine. The hollow is made to produce the interlocking brick in the precise size and shape. This machine is operated in contrast to automated brick making equipment. With the aid of controlled levers, handles or other devices the operator completes the different procedures involved in creating bricks. The device has a material hopper which is typically at the top. The mixture of raw materials is poured into the brick forming cavity using a conveyor.

By using a levered or handled mechanism the individual using imparts its certain amount of force or pressure to the raw material. By compressing the material inside the cavity this force assures appropriate brick formation. The structure of machinery consists of mechanisms or processes that allow bricks to interlock. As an integral component of this process the bricks may have extensions and holes drilled into their sides to guarantee a snug fit when packed. Once the brick is prepared and has had time to properly eliminate and then use a tool to remove the brick from the cavity. This function may involve actively pushing a lever or handle to release a brick.

Key Features of Single Cavity Interlocking Brick Making Machine

Some of the essential characteristics of double cavity interlocking brick making machines are listed below:

Formation of the bricks: In order to create interlocking bricks the machine is made for shaping and moulding the raw material composition. The material is put in the cavity and crushed to form the ideal brick shape.

Interlocked Structure: This equipment includes elements that allow for the creation of interlocked bricks. Such characteristics enable the bricks to be fitted safely together when packed by producing the requisite extensions and recesses on each side.

Operation of the machinery: The user controls the device manually. This entails putting raw materials into the equipment compacting them inside the cavity with pressure and then releasing the lever to discharge or evict the finished brick.

Material Feeding: The machine includes a material feeder that allows the user to pour the raw material mixture into the cavity. This ensures a consistent and controlled amount of material is used for each brick.

Brick Ejection: Once the brick has been formed and set, the machine provides a mechanism for ejecting the brick from the cavity. This allows for easy removal and handling of the produced brick.

Versatility: A manual brick making machine can be used to produce different sizes and shapes of interlocking bricks. The machine’s design allows for flexibility in creating bricks that suit specific construction requirements.

Small-Scale Production: Manual brick making machines are often used for small-scale production or in areas with limited access to electricity or automated machinery. They provide a cost-effective solution for brick production in such settings.

Portability: Some manual brick making machines are designed to be portable, allowing for easy transportation and use at various construction sites or locations.

Uses of Single Interlocking Cavity Interlocking Brick Making Machine

There are many applications for a single cavity interlocking manual brick making machine, particularly in construction and building projects. Here are a few typical examples:

Building Houses: Interlocking bricks made by the machinery can be used to create homes and other residential structures. Since no mortar or cement is required and therefore they offer a practical and long lasting substitute for conventional bricks.

Walkways and Pavements: Interlocking bricks are frequently employed to build walkways, patios and pathways. Practically beautiful and useful pathways can be created using the machines ability to build bricks in a variety of patterns and hues.

Gardening and outdoor tasks: The device interlocking bricks can be utilized for retaining walls, garden edging and other landscaping elements. Due to their stability and ease of setting up and thus they are commonly utilized for outdoor uses.

Environmentally sustainable building method: Soil, cement and other locally obtainable resources are frequently used to make interlocking bricks which are also known as green construction materials. By decreasing dependency on conventional bricks and thus preventing environmental effect using a interlocking brick making equipment encourages sustainable building practices.

Rural and distant locations: In rural and remote locations with limited access to electricity and mechanized equipment interlocking brick making machines are specially helpful. They give local brick manufacturers an economical and convenient choice enabling localities to embark on building projects on their own.

Production of bricks in small scale: The machinery is capable of manufacturing bricks on a small scale to meet the demands of one person, a small business or non-profitable organization. The device help provides a workable answer to manufacturing bricks on a smaller scale rather than the use of costly and technologically advanced equipment.

Training and skill improvement: can be accomplished with the aid of interlocking brickmaking equipment’s. They give people the chance to pick up brickmaking skills and obtain real-world experience in activities associated with construction.

Benefits of Single Cavity Interlocking Brick Making Machine

The following are some benefits of single cavity interlocking brick making machine:

Production efficiency: It is improved because interlocking brick machines can produce bricks considerably more quickly than conventional techniques like hand moulding or extrusion. When it comes to large scale projects in particular which can result in much higher production efficiency.

Reduces labour costs: Because interlocking brick machines are so automated, relatively little manual work is necessary. By doing so the labour expenses may be decreased and total profitability may increase.

Better quality of the product: Compared to regular bricks, interlocking bricks are often more homogeneous in size and shape. This is because a precise mould is used to create them. Interlocking brick walls are hence more robust and long lasting.

Budget friendly building products: Interlocking bricks can be produced from a number of products in order which include concrete, ash from combustion and recycled components. Interlocking bricks could become more beneficial to the environment as a result and thus the costs for materials possibly can decrease.

Adaptability: Many different kinds of building tasks comprising buildings, outdoor spaces, pathways and roads that can be built with interlocking bricks. They are an adaptable alternative for projects of all kinds because they come in wide range of different colours and designs.

Lessen the application of cement: The application of cement can be significantly minimized by using interlocking bricks instead of mortar when laying the base of the building. Both money and environmental effect may be saved as a result .

Improved thermal insulation: This technology is made possible by the single cavity found in interlocking bricks. This can lower heating and cooling costs and increase a buildings energy efficiency.

Lower disturbance aspects: Because interlocking bricks are quieter than conventional bricks, they provide a fantastic solution for houses and businesses located in noise sensitive locations.

How the Single Cavity Interlocking Brick Making Machine Works?

Making single cavity interlocking bricks involves compressing a concrete and other material mixture into the required shape using a mould. The single cavity of the mould which is commonly composed of steel or cast iron lends the brick its distinctive single cavity design. The concrete mixture is loaded into the machine’s hopper to start the brick-making operation.

The slurry is then put into the mould using a screw auger or conveyor belt. When the mould is full a hydraulic press uses high pressure to compress the mixture into a brick like shape. The brick is then released after opening the mould. The expelled brick is then set up to cure on a pallet. The concrete hardens and becomes stronger during the curing phase which normally lasts a few days. The bricks are prepared for use in construction once they have cured. Building walls and other buildings out of interlocking bricks is quick and simple since they can be set without the use of mortar.

Following is the step by step process of Interlocking Single Cavity Brick Making Machine:

- The machine’s hopper is filled with the concrete mixture.

- A conveyor belt or screw auger is used to feed the concrete mixture into the mould.

- When the mould is full, a hydraulic press uses high pressure to compress the mixture into a brick-shaped shape.

- The brick is then released after opening the mould.

- The ejected brick is then set up to cure on a pallet.

- The concrete hardens and becomes stronger during the curing phase which normally lasts a few days.

The bricks are prepared for use in construction once they have cured.

A machine that creates interlocking bricks out of a mixture of concrete, sand and water is known as an interlocking single cavity brick making machine. The machine only has one cavity therefore it can only create one brick at a time. Machines that produce single cavity interlocking bricks are either manual or semi-automatic. When using a manual machine, the operator must manually pour the mixture into the cavity and then push the mixture into shape using a lever.

In semi-automatic machines, the operator simply needs to use the lever to press the mixture into shape; the hopper automatically feeds the mixture into the cavity. Making interlocking bricks with a single cavity is simple and reasonably inexpensive. In addition, they are exceedingly adaptable and can be used to make a wide range of interlocking bricks including pavers, retaining wall blocks and fence blocks.

Frequently Asked Questions

When purchasing an interlocking single cavity brick building machine, it’s important to keep the following in mind:

- Production capacity, brick type, and power source are all factors.

- Automation level

- Needs regarding durability and the maintenance

- Price

- Brand recognition

- Post-purchase assistance and service

Benefits of interlocking single cavity brick making machines includes more durable and stable walls, lower costs for materials, accelerated construction, better insulation and environmental friendlier operations.

- Compared to conventional bricks interlocking bricks can be more challenging to repair or replace.

- Bricks that interlock could not look as good as bricks that do not.

- Compared to conventional bricks interlocking bricks might not be as commonly available.