Home > Moulds

MOULDS

Moulds Crafting excellence

As precision touches technology and shapes our civilization, cast moulds are the silent heroes of the manufacturing world that shape our modern industry. As these pieces lay behind the transformation of liquid substances into solids, miniature objects. Cast Molds- Unlock the potential for exponential growth with the ease of operation and perfection in every moulding. Casting process involves pouring of molten material into a mould cavity to form a solid object.

Key features of moulds

Moulds are important components in manufacturing for several reasons:

Precision and Reproducibility: This enables to produce number of identical components in the same quality and accuracy through cast moulds. moulding makes it possible to reproduce complex forms and small parts precisely.

Versatility: These materials offer great flexibility in designing various commodities such as automotive spare parts including engine blocks or airplane components and consumer products like household appliances.

Complex Geometries: This is advantageous because when using casting processes, one can manage to make items of intricate geometry involving under cuts, finer details which are hard to obtain otherwise.

Cost-Effectiveness: Casting is a cost-efficient method for high-volume production. By producing many parts from a single mould, an economy of scale can offset the cost of initial mould creation.

Advantages of using cast moulds

Material versatility: various forms of materials can be applied into different casting processes, materials generally used are metals, plastics, and ceramics.

Complex shapes: cast moulds can easily reproduce objects and shapes which are difficult to create with the best precision and durability.

Cost and time efficient: cast moulding is widely used for mass production, this feature makes it cost efficient and at the same time it can reproduce numerous distinct objects within a given time frame with best efficiency possible.

High precision: moulding empowers the production process to be more precise and accurate without leaving any scope for deformity and correction, every casting is assured to be perfect and durable with the use of moulds.

Common casting processes performed by using cast mould

Sand Casting: One of the oldest and common methods of casting is sand casting. This process entails making a cavity in sand, and then melting and pouring metal into it. Sand casting allows the production of large pieces of metal.

Investment Casting: This involves a pattern made of wax or plastic which is enclosed in ceramic shells. A pattern made of wax or plastic is heated, causing it to melt or burn-out and create a cavity that gets filled with molten metal. Investment casting is applicable in making complex and highly accurate parts.

Die Casting: Molten material is forced into a mould cavity under high-pressure during die casting. The technology used is very automated and produces high quality dimensional tolerances and surfaces. This is applied heavily in vehicles and electronics production.

Plastic Injection Moulding: Plastic-making through injection is done by injecting molten plastic into the mould cavity using a mould. It is an important ingredient in the manufacture of consumables, packaging materials, and plastic products.

Rotational Moulding: In this case, a mould is heated to rotate as it picks up the material coating the inside of the mould and forming a hallow cavity. It is an instrument that is typically utilized in a large capacity, particularly for items like tanks for bulk storage or swings.

Consideration and limitations

Every process has its own limitations and drawback to same in the case of moulding is also seen such as:

Initial cost: utilizing mould may be cost efficient in long run but creating a mould itself is a lengthy and expensive procedure, designing, alteration and shaping requires a lot of time as well as its expensive.

Material constrains: material selection should be considered before casting as casting material impacts the final product, different moulds and products requires specialized materials for mould crafting, different kind of products uses different materials as well as specified moulds.

Post-processing: depending on the casting method to be followed, post-processing may require excess material to be removed, improve surface finish and ensure accuracy with perfection.

Types and forms of mould available with lotus traders

Lotus traders is well known for its quality services and top-quality products. Lotus traders is the one stop destination for all your construction requirements and equipment.

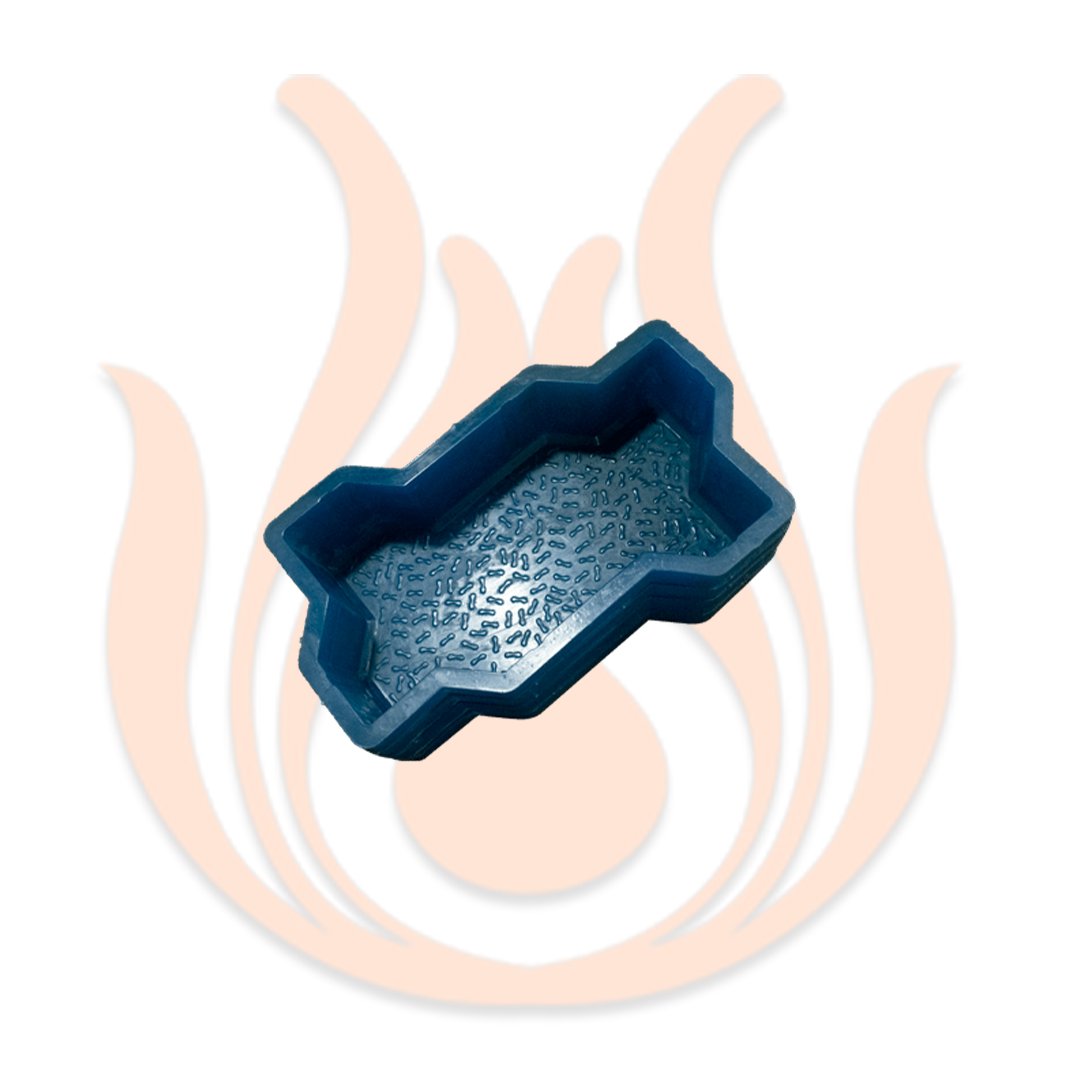

Plastic mould: These moulds vary in design and size, allowing them to be used in concrete blocks, pavers, and other structurally and aesthetically appealing objects in construction. Such moulds are built of sturdy plastic and available in different shapes and styles to convert concrete to a particular shape or configuration. Plastic moulds streamline the production process by decreasing labour, they facilitate faster production of delicate and sophisticated designs hence they are essential in improving appearance and functioning of any produced object.

Iron mould: This mould refers to solid and sturdy casts for diverse building materials such as cement and masons are the most used materials into iron mould. These moulds are made from robust iron or steel specially designed for withstanding the harsh conditions of construction sites. They are commonly employed for producing concrete beams, columns, and other structural elements. Ensuring durability with precision, iron moulds play the most crucial role in assuring structural integrity and safety of every project.

PVC mould: this mould is used for casting statuary products such as decorative columns, balusters, and paving blocks. The lightweight nature of PVC allows for easy handling and still can produce patterns that is cost effective and perfect. The best advantage of using PVC mould is that they are flexible, reusable.

Ventilation mould: Ventilation moulds are special moulds which are designed in such a manner to ensure that there is an opening duct or channel to enhance ventilation of the structure. Mold has been used as a critical moulding tool to shape spaces that support good ventilation, which helps in maintaining interior air qualities and temperature. HVAC (Heating, Ventilation, and Air Conditioning) usually employ ventilation moulds to provide buildings with effective and properly designed air intakes and exhausts. The moulds enhance indoor air control thereby improving human comfort in a building.

Moulds are part of manufacturing technology, which makes it possible to produce complex precise objects that can be repeated many times over. There are numerous casting methods such as sand casting, investment casting, die casting, plastic injection moulding, and rotational melling among others for various industries and material demands. The practicality, precision and cost-effectiveness of cast moulds are important aspects for inclusion in present manufacturing; nevertheless, first expenses as well as material considerations do not eliminate their vital role into modern production. Industries worldwide are shaped by their potential of converting raw materials to finished products in the fields of automotive, aerospace, consumer goods and others.

Frequently Asked Questions

Usually, four types of moulds are taken in work for producing any object repeatedly, moulds are chosen according to specification and requirement such as:

- Plastic mould.

- Glass mould.

- PVC mould.

- Ventilation mould.

- Iron mould.

Mould is the most accepted term by general public, while Mold is widely used in UK and western states.

Permanent iron moulds are universally used for metal casting for being able to endure the high temperature and pressure of the molten fluid.

Sand casting is the most affordable as well as the cheapest form of casting.

The lifespan of a mould depends upon the material used for casting as well as the details present in the mould and material of the mould itself plays a crucial role in longer lifespan, however on an average 50-80 cast is considered to fully utilized before replacing the mould.

Material used in casting are metals or various time setting materials that cure after mixing various components together.

Steps for casting process are:

- Core making.

- Melting and pouring.

Depending on the type of casting, the cost may vary. A aluminium or steel casting can be very expensive, especially if they are made with high quality materials.

Yes, casting moulds can be reused again and again for producing patters and products, but after certain period the usability and precision of the end product will degrade and the mould will become unusable.