Home > Iron Moulds

IRON MOULDS

Iron mould: Give beautiful structures to your construction ideas.

Iron moulds used in construction are made of iron which gives structure to concrete and construction accessories. They are used in construction sites, fir shaping structures, beams and other construction elements. They are durable and can form various shapes, which makes them the best choice in construction. These moulds can withstand high temperature Iron moulds ensure a quality product that meets all the standards. These moulds are reusable, customisable and are cost effective, ensuring precision in its work. Various types of iron moulds cater to specific applications, offering benefits like high heat resistance and reusability. Proper maintenance ensures their longevity, making them essential in mass production and industrial settings.

Key features of iron mould:

Here are some key points of iron mould:

Durable: Iron moulds are durable. They can tolerate rough weather and can be used again and again without any compromise in the outcome quality.

Reusable: Iron moulds are reusable. It can be used frequently, thus making them pocket friendly. This reusability advantage of such moulds minimises replacing, which saves both time and capital.

Precise: Iron moulds are used to precisely create concrete design. The outcome of the design is precise and meets all the standard requirements.

Smooth Finish: Iron moulds work with utmost precision and provide smooth lavishing surfaces which are pleasing to customers.

Versatility: Iron moulds are versatile and can be used to design various construction elements, which includes columns, beams.

Strengthening: Iron moulds are vigorous and can withstand heavy weight of concrete, which ensures the toughness of infrastructures.

Customisable: Iron moulds are easily customisable into different shapes or designs as per the construction requirements.

Consistent: Iron moulds remain consistent throughout the construction process, which minimises errors and ensures stability and precision in the final outcome.

Fire control: Iron moulds are incombustible, which gives a great advantage in the field of construction to prevent any kind of accident.

Environment Friendly: As iron moulds are reusable, they contribute to sustainable development by minimising waste.

Usage of Iron moulds in construction:

Following are the uses of iron moulds.

Concrete moulding: Iron mould shapes and supports concrete structures. These moulds can fabricate different construction accessories such as pillars, walls and beams efficiently.

Congeal Concrete: Iron moulds are used to congeal concrete for creating decorative accessories. These moulds maintain the standardisation aspect.

Decorative Tiles: Iron moulds also help to form tiles and decorative elements. These moulds can design many types of patterns.

Sewer hole Covers: Due to the toughness and longevity nature of iron, these moulds are used in sewer hole covers and other heavy covers.

Creating decoration accessories: Iron moulds can also create decoration accessories such as decorative fencing, banister, in construction sites.

Customisable: Iron moulds are customisable and can be used to create any kind of shapes and sizes, giving an exposure of ideas to designers.

Bridge constructions: Iron moulds are used in bridge construction to create elements such as beams, bridge end, and railings, which ensures structure strength and durability.

Benefits of iron mould in construction:

- They are versatile as they can form any design and shapes as per the designer requirements.

- They can be reused again and again, thus ensuring cost effectiveness.

- They are easily customisable and can be given different shapes and sizes.

- They are durable and can withstand high temperature and pressure.

- They are highly resistant to fire, ensuring safety in the construction site

Products and services provided by lotus traders for iron mould:

Following are some commonly used iron moulds supplied by Lotus traders:

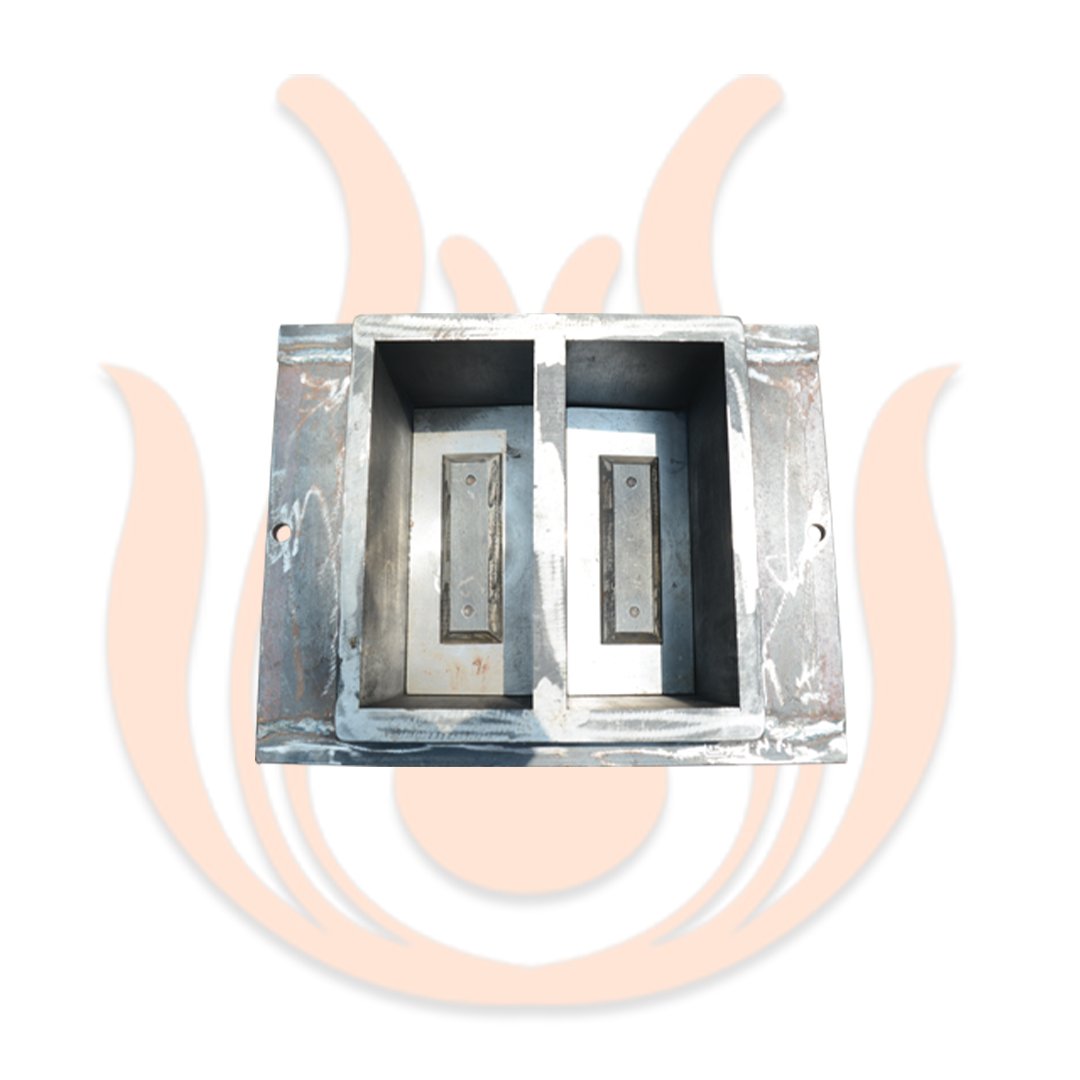

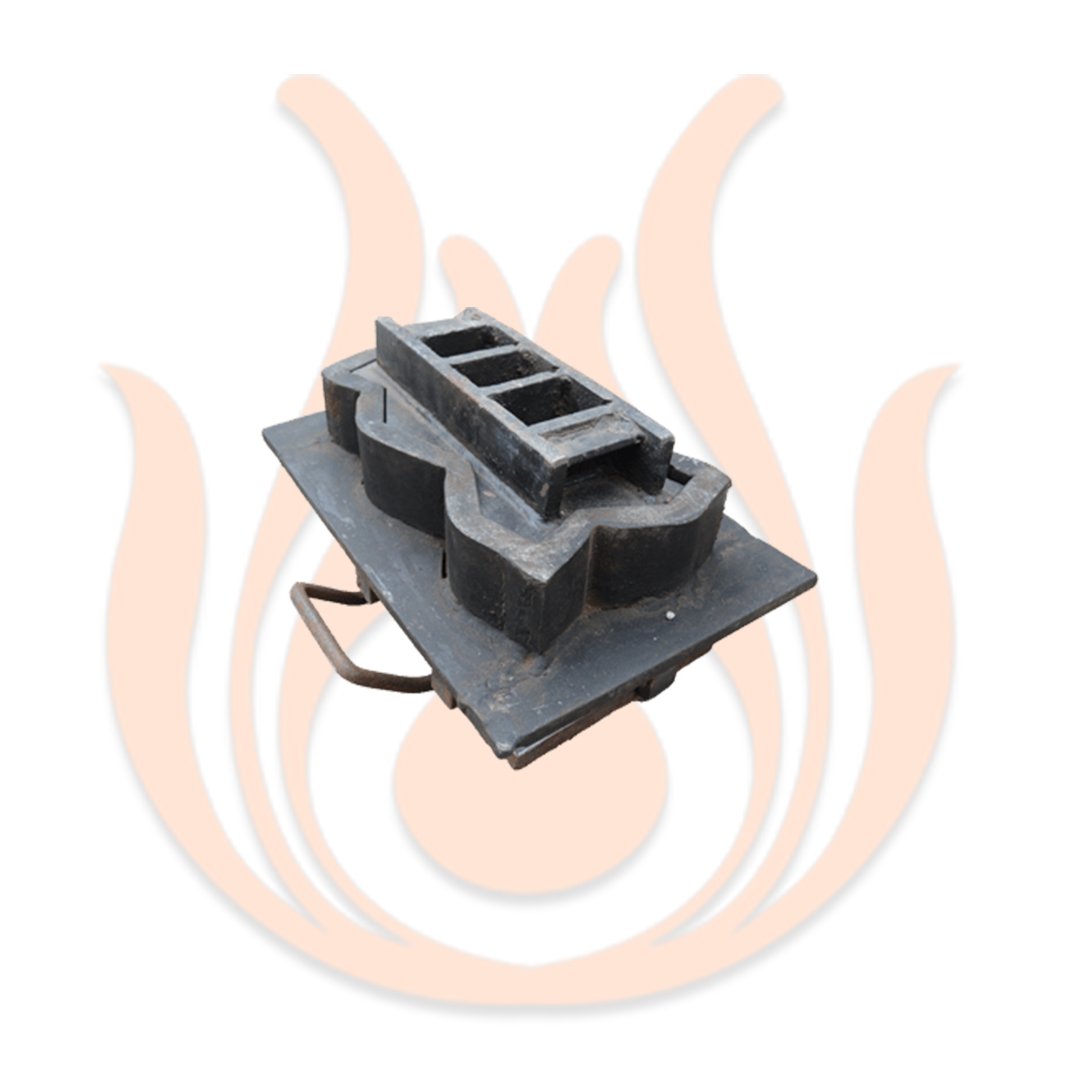

Brick 4 Cavity Mould: The iron 4-cavity brick mould used in brick manufacturing has the capacity to produce four bricks at the same time. These moulds can handle high pressure and heat evolved during brick processing.

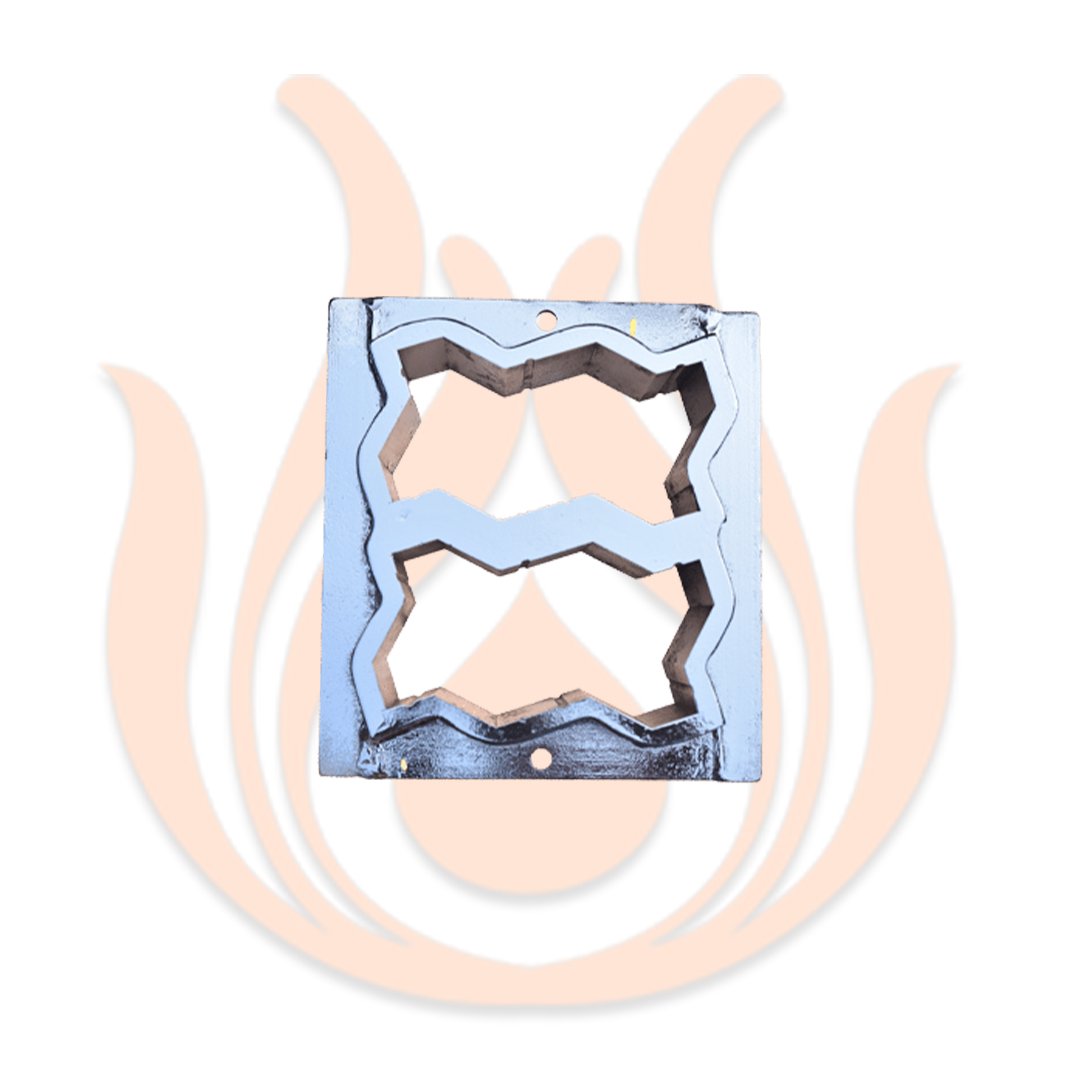

Zig-Zag Double Cavity Mould: Zig-Zag Double Cavity Mould made up of iron are used in the production of zigzag pattern concrete designs. They can produce two bricks at once. They are durable and offer great heat resistance. It is about 80mm in size.

Brick 2 Cavity Mould: Brick 2 Cavity Mould made up of iron are used in brick manufacturing. These moulds can produce 2 bricks at the same time. These moulds are durable and can handle high pressure and temperature. It is about 9x4x3 inches in size.

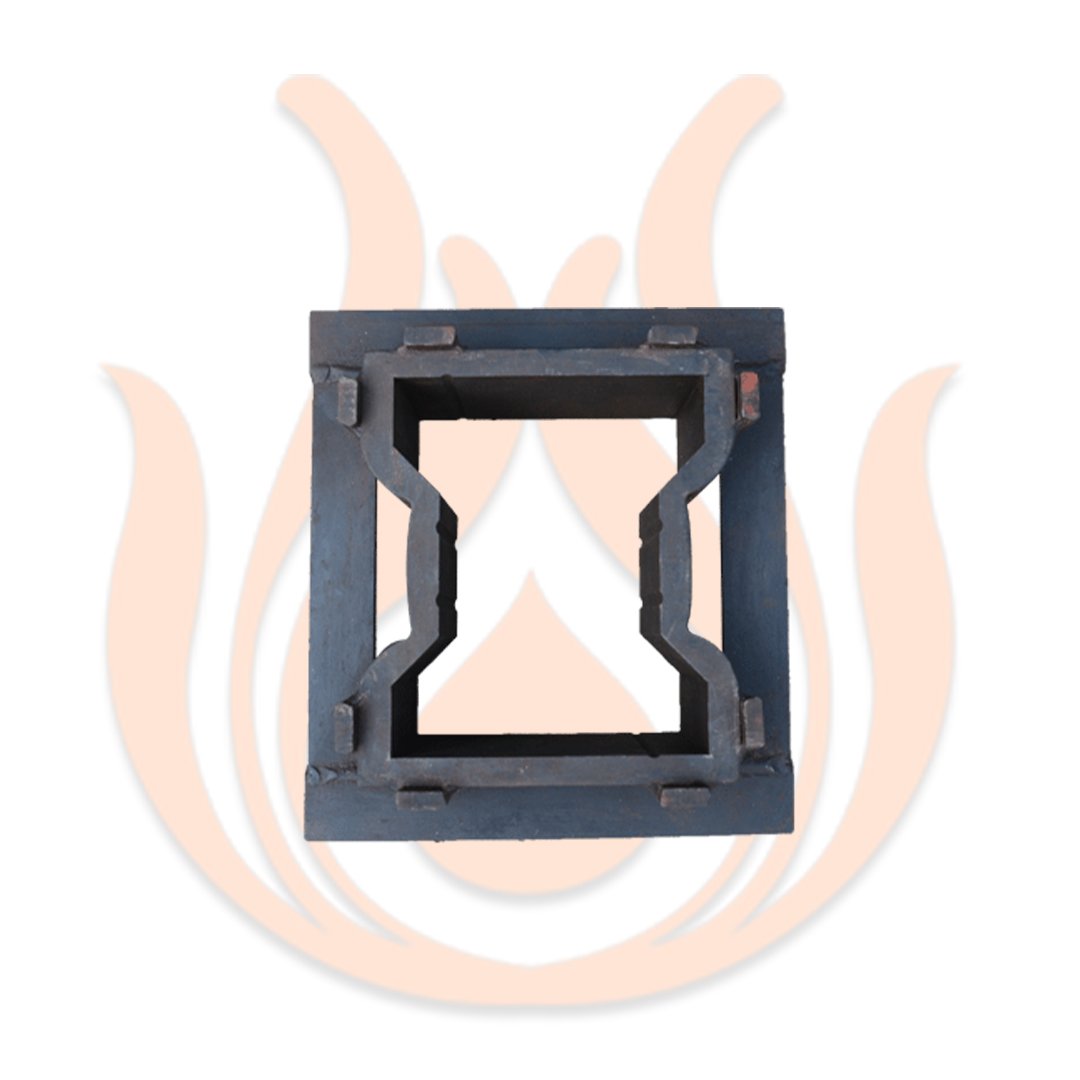

Hexagonal Mould: Hexagonal mould made of iron has six sides and is used to prepare six-side mould design. They shape concrete for construction units. It is about 80 mm in size.

Single Cavity Brick: Single cavity brick mould made of iron is used for shaping and forming individual bricks. It has a single chamber where the material is poured. It has a size of about 9x4x3 inches.

Zig-Zag Single Cavity: Zig-Zag Single cavity Mould made up of iron are used in the production of zigzag pattern concrete designs. They can produce one brick at a time. It is about 60/80 mm in size.

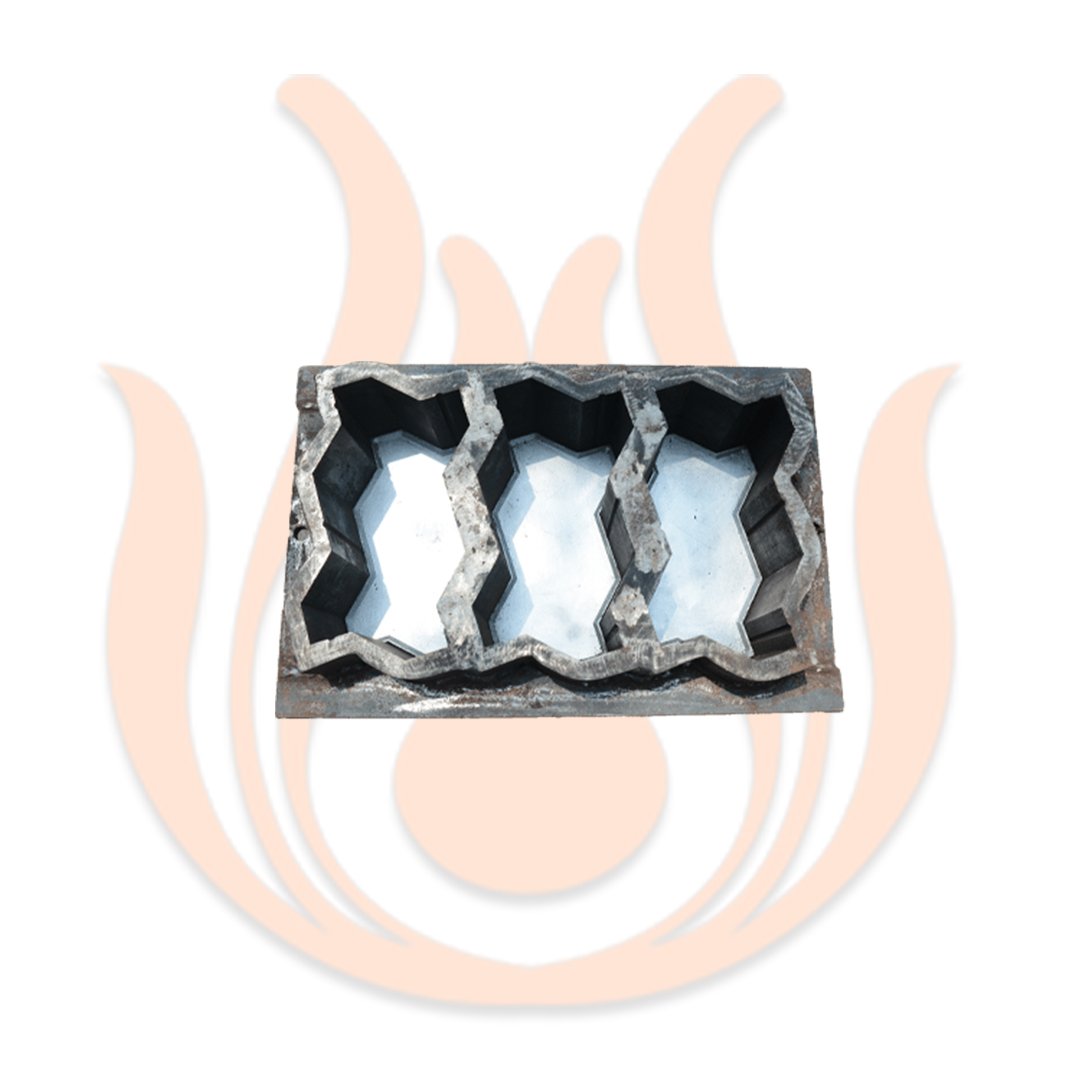

Zig-Zag 3 Cavity: Zig-Zag 3 cavity moulds made up of iron are used in the production of zigzag pattern concrete designs. They can produce three bricks at a time. It is about 80 mm in size.

Brick 3 Cavity: Brick 3 Cavity Mould made up of iron are used in brick manufacturing. These moulds can produce 3 bricks at the same time. It is about 9x4x3 inches in size.

Designs are the highlight of the infrastructure. Different shapes and patterns give a classy look to your infrastructure. Designers get to experience innovative and creative ideas when working with iron moulds because they are customizable. These moulds can withstand high temperatures, pressures and harsh conditions, making it durable and has a long lifespan.

To design your dream ideas, be it for your home or for building bridges and large infrastructure, it is of utmost importance to choose good quality iron moulds at an affordable price. The right place to buy all your products is from Lotus Traders, as we have years of experience and we provide the highest quality products, ensuring efficiency and durability of each product

Frequently Asked Questions

Iron moulds made up of iron are used in construction to provide support, shape and sizes to concrete.

The different types of iron mould provided by Lotus Traders are :-

- Brick 4 Cavity Mould

- Zig-Zag Double Cavity Mould

- Brick 2 Cavity Mould

- Dumble Single Ring

- Dumble Single Set

- Hexagonal Mould

- Single Cavity Brick

- Zig-Zag Single Cavity

- Zig-Zag 3 Cavity

- Brick 3 Cavity

The advantages of using iron moulds are :-

- They are versatile, they can be moulded to different shapes and sizes.

- They are modifiable.

- They handle high pressure and temperature.

- They have a longer life span.

Materials that can be shaped using iron moulds are – metals, plastics, glass, concrete, ceramics, rubber, and composite materials.

Yes, iron moulds are environment friendly due to their reusability nature, which ultimately reduces waste.

Maintenance of iron moulds can be done by the following ways :-

- They should be inspected from time to time to make sure there are no damages.

- They should be cleaned after every use.

- Painting should be done on a regular basis to resist rusting.

Following safety precautions should be considered while using iron moulds :-

- The workers have to be properly trained and should be familiar with the handling of the moulds, to prevent accidents.

- Wearing of safety equipment, such as gloves, helmets and other protective wears are important.

- Regular inspection of iron moulds is important, to prevent any damages and rusting.

Iron moulds are fixed prior to pouring concrete. After the concrete has been fixed properly, removal of concrete is done slowly to avoid any damage to the mould so that it can be reused again.

Iron moulds can be used for both domestic and commercial purposes. Due to their versatile nature, they can be used to shape and design for various purposes, including home decor as well as for building large infrastructures.

Iron moulds have a larger lifespan, but it needs to be maintained. Any damage done to the mould can hamper its life span.