Home > PVC Mould

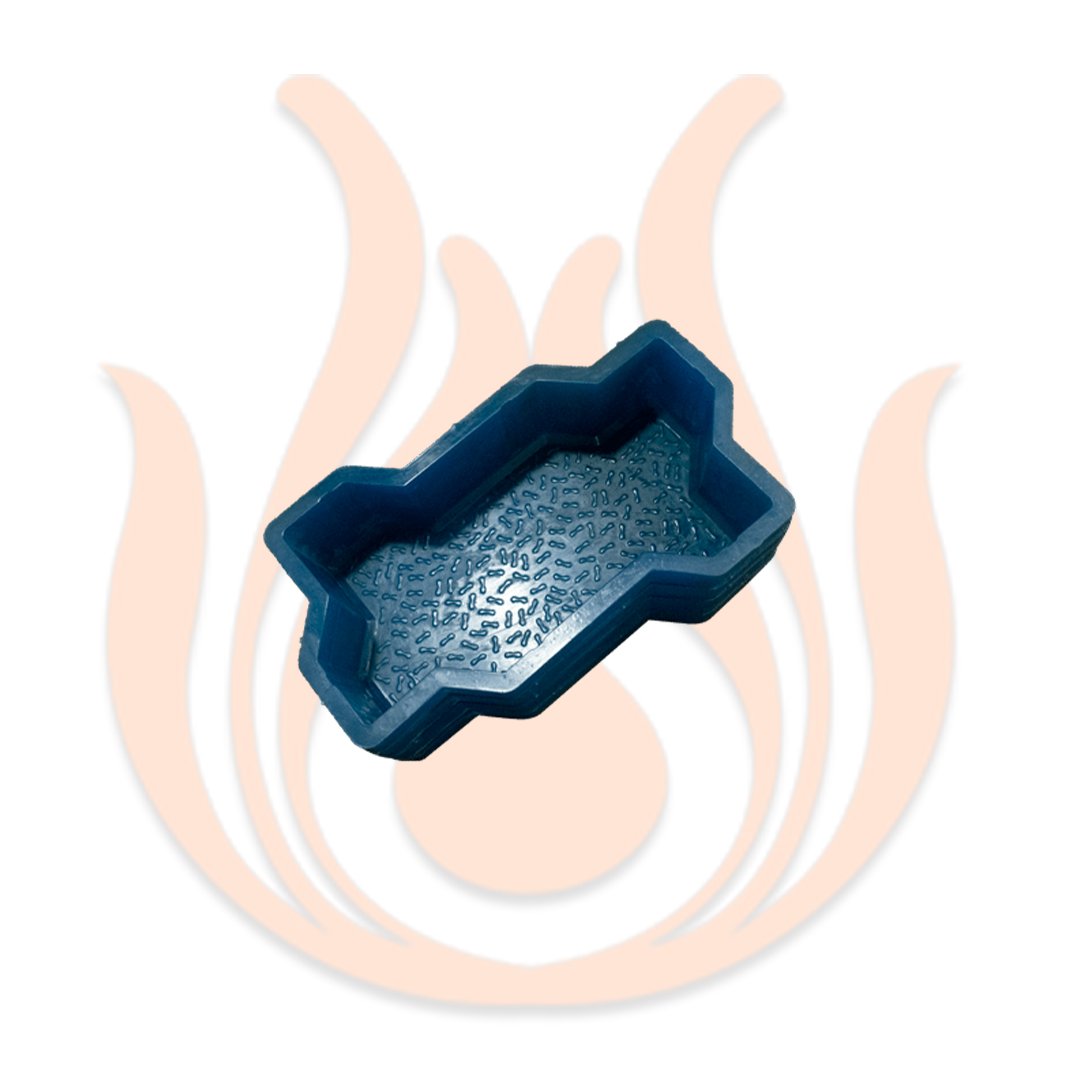

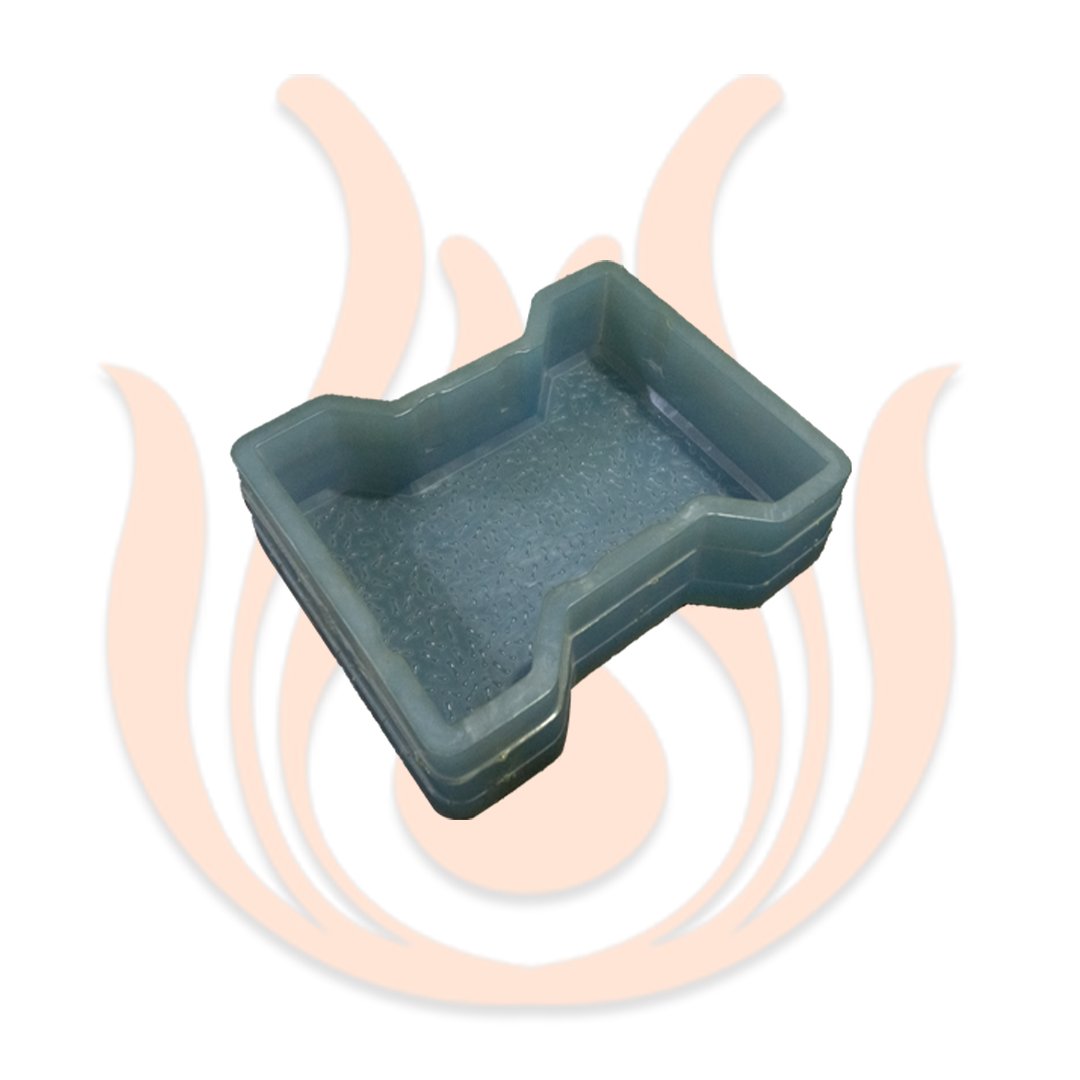

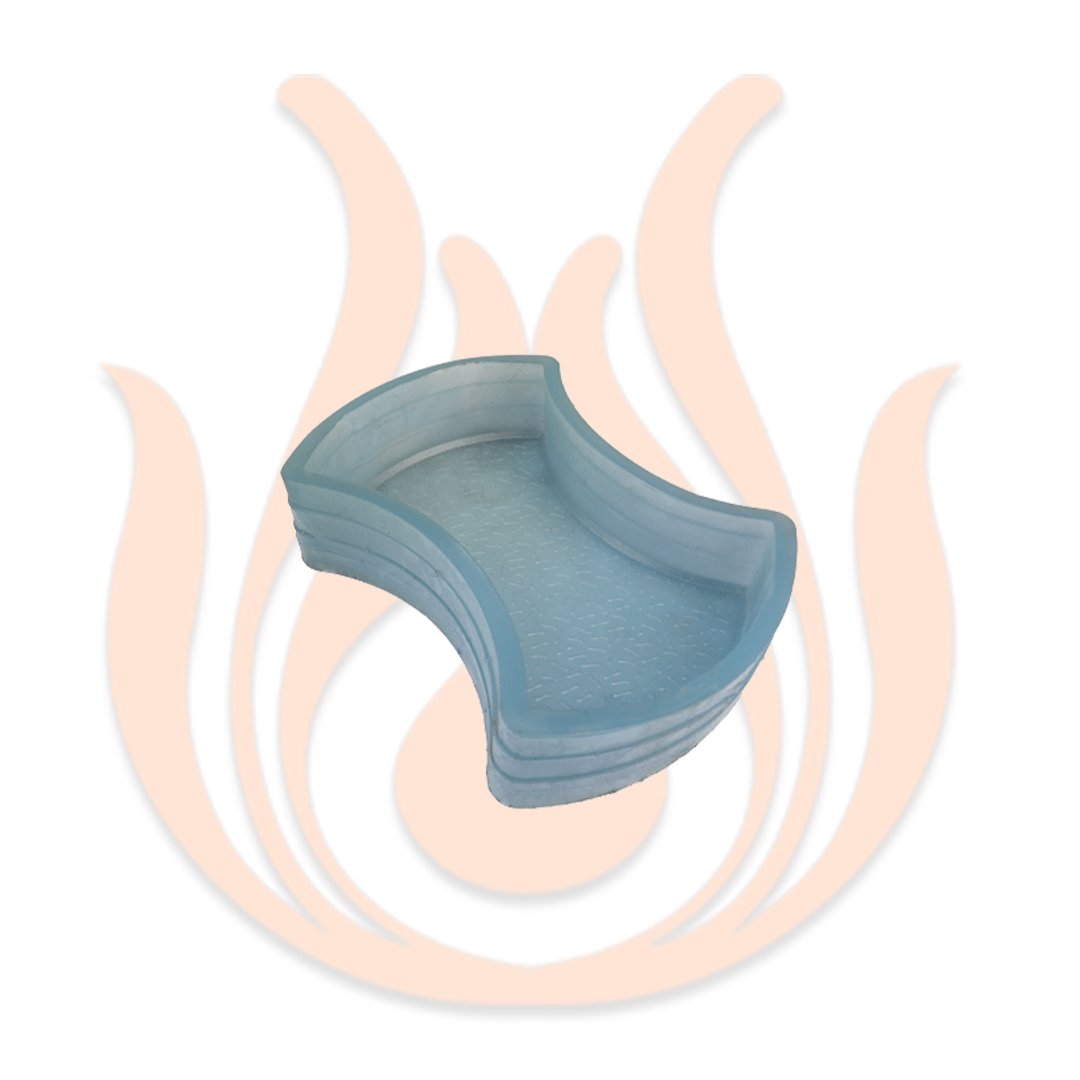

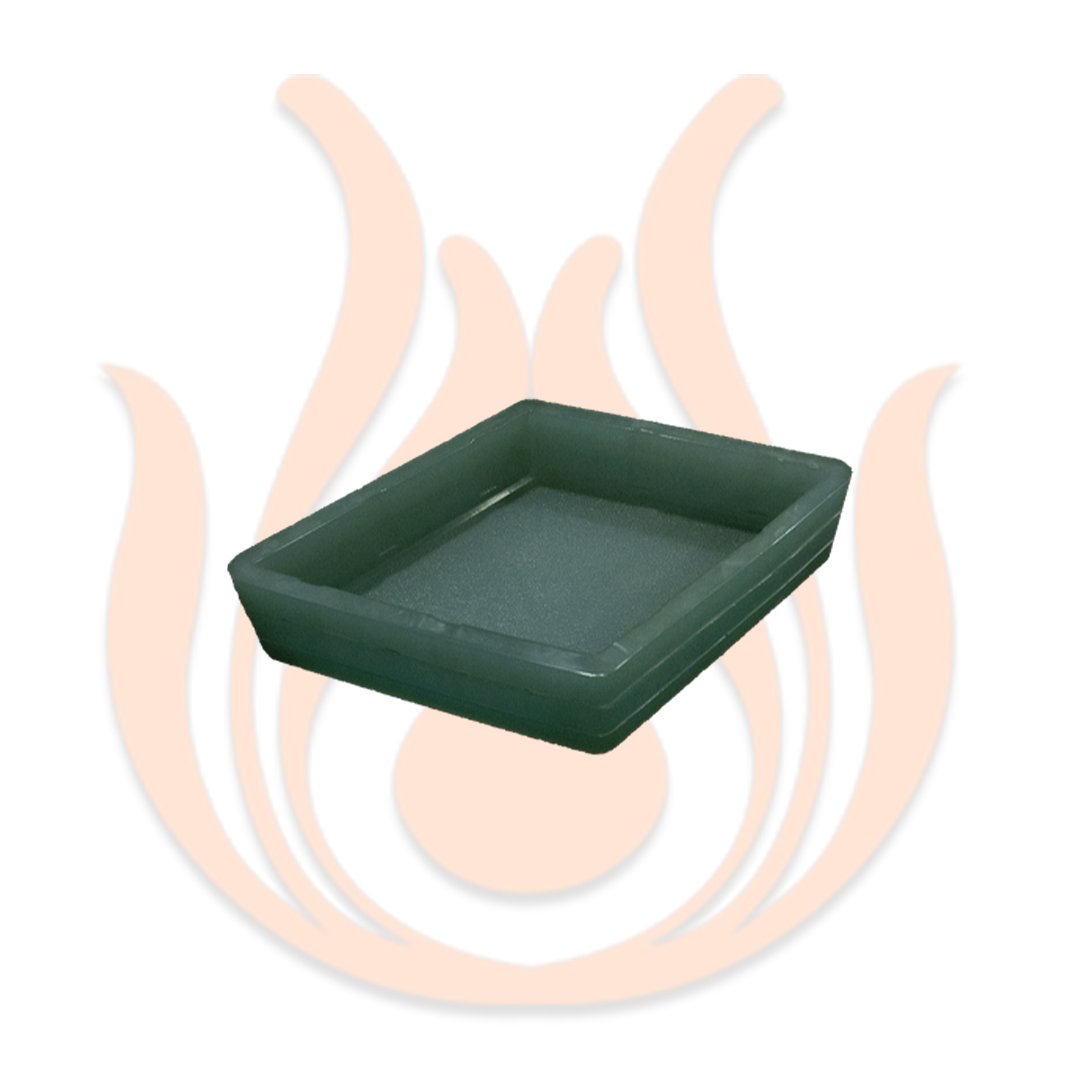

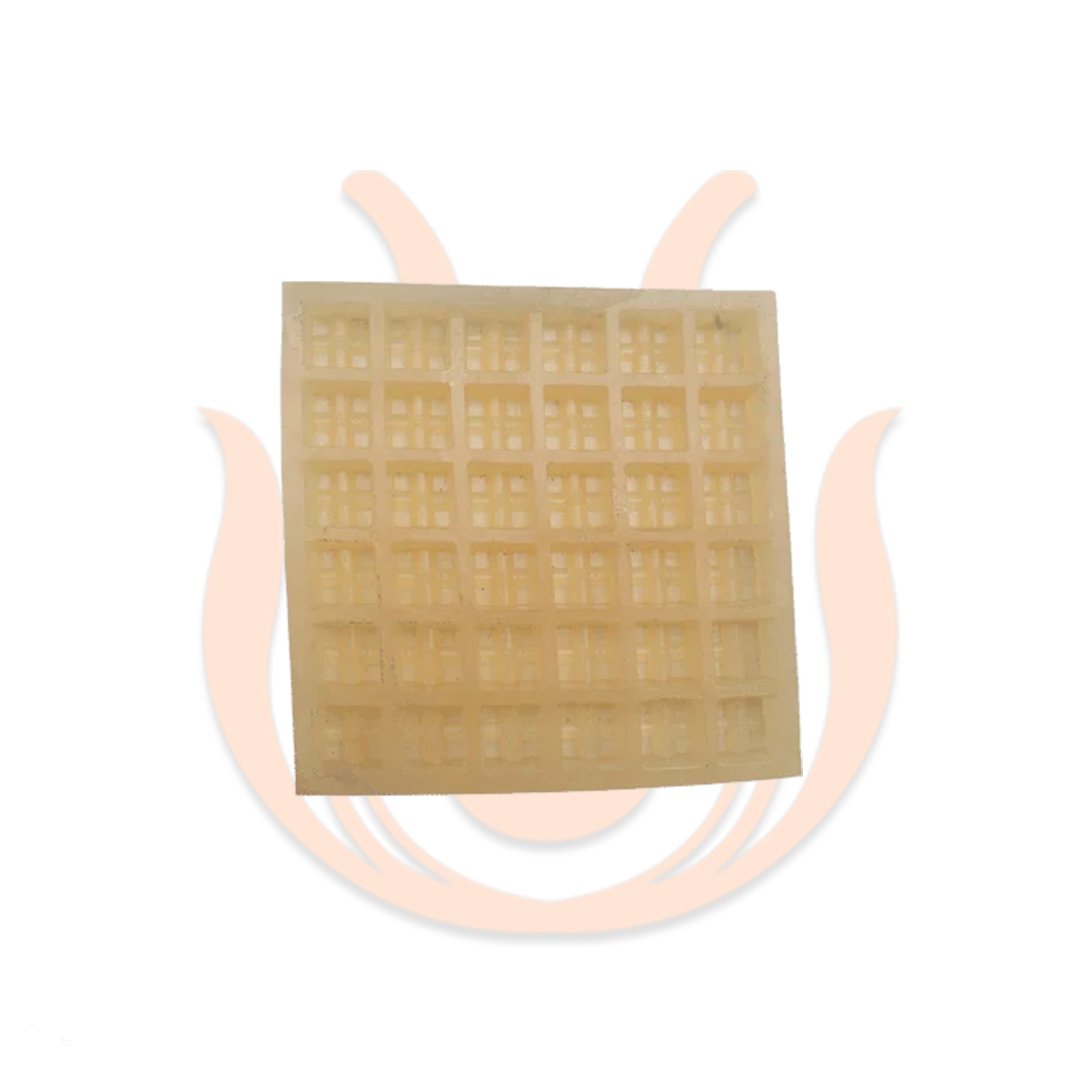

PVC MOULD

PVC moulds used in construction are lightweight, durable, and versatile tools designed for shaping concrete into various construction elements like slabs, beams, and columns. Made from high-quality PVC, these moulds are resistant to corrosion and can withstand harsh conditions. They are easy to handle, reusable, and offer precise moulding for consistent results. PVC moulds are cost-effective, customizable, and ideal for projects that require fast production and high-quality finishes.

Description -

PVC moulds used in construction are lightweight, durable tools designed for shaping concrete into various construction components such as beams, slabs, columns, and decorative elements. Made from high-quality PVC, these moulds offer excellent resistance to corrosion, moisture, and wear, making them ideal for both indoor and outdoor use. They are easy to handle, ensuring quick setup and efficient use on construction sites.

PVC moulds provide precise and consistent shapes, ensuring that the final concrete product meets required specifications. They are also reusable, which makes them a cost-effective solution for projects requiring multiple castings. These moulds can be customized to fit specific project needs, offering flexibility in design and production. Additionally, they require minimal maintenance, contributing to their long-lasting performance.

Due to their lightweight nature, PVC moulds are easier to transport and handle compared to traditional metal moulds, which helps reduce labor time and costs on site. Their ability to produce high-quality, uniform concrete elements makes them a popular choice for both large-scale industrial projects and smaller construction tasks.

Specification:

The PVC moulds used in construction typically have the following specifications:

Material:

- Made from high-quality PVC (Polyvinyl Chloride), ensuring durability, corrosion resistance, and lightweight properties.

Shape and Design:

- Available in a variety of shapes and sizes to form different concrete elements like beams, columns, slabs, and decorative structures.

Durability:

- Resistant to moisture, wear, and corrosion, making them suitable for long-term use in both indoor and outdoor environments.

Reusability:

- Designed for multiple uses, reducing the cost of material replacement and making them ideal for high-volume casting.

Temperature Resistance:

- Capable of withstanding typical concrete pouring temperatures without deforming, ensuring a stable and reliable moulding process.

Weight:

- Lightweight and easy to handle, reducing the effort and time required for setup, transportation, and storage.

Customization:

- Available in various sizes, allowing for tailored designs based on specific construction needs, and can be easily modified for unique shapes.

Surface Finish:

- Smooth internal surfaces to ensure easy release of the concrete, leading to a clean, high-quality finish on the final product.

Maintenance:

- Requires minimal maintenance, and typically can be cleaned quickly after use, ensuring extended life with proper care.

These specifications make PVC moulds a popular and effective choice for shaping concrete in construction projects, offering efficiency, precision, and cost-effectiveness.