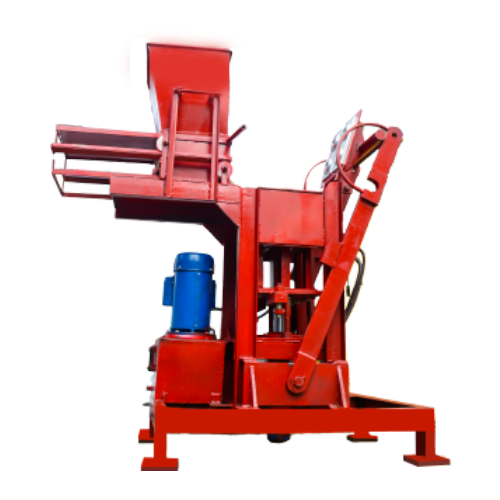

Single Cavity Semi Automatic Block Making Machine

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURES | SPECIFICATION |

Capacity | 2000 / Shift |

Power Pack | 5 HP (3 Phase) & 7.5HP (3 Phase) |

Usages | To make Pressurize Concrete Block |

Process | Hydraulic |

Pressure | On 5 HP 2000 PSI/ On 7.5 HP 3000 PSI |

Operation | Semi-automatic Push Button Type |

Block Can Be Made | I shape, Zigzag, colaredo, Bricks & Tiles mould 10×10 Inch |

What is Single Cavity Semi Automatic Block Machine

A semi automatic single cavity block making machine, is a piece of equipment used for manufacturing concrete or cement blocks. It is designed to produce a single block at a time, making it suitable for small-scale production or for individuals and businesses with lower production demands

Key features and Components of Semi Automatic Single Cavity Block Making Machine:

- Frame : The machine consists of a sturdy frame made of steel or cast iron, providing stability and support for the various components.

- Hopper : The machine has a hopper at the top where the raw materials, such as cement, sand, aggregates, and water, are loaded.

- Mixing chamber : This is where the raw materials are mixed together to form a consistent and homogenous mixture. The mixing chamber may have blades or paddles to ensure thorough mixing.

- Mould : The machine includes a mould that determines the shape and size of the block being produced. The mould is typically made of steel or cast iron and can be customized to produce blocks of different sizes and designs.

- Vibrating table : Once the mixed material is transferred into the mould, a vibrating table is used to compact and settle the mixture evenly within the mould. The vibration helps to remove air pockets and ensure proper density and strength of the block.

- Hydraulic or manual pressure system : Depending on the machine's design, it may employ either a hydraulic or manual pressure system to compress the material within the mould and form the block. Hydraulic systems are more common and provide greater force and control

- Ejection mechanism : After the block is formed and has cured for a specific period, the ejection mechanism releases the block from the mould. This can be achieved through mechanical or hydraulic means.

- Control panel : The machine may have a control panel with buttons or switches to operate and control the various functions of the machine, such as mixing, vibration, and ejection.

Enhanced Semi Auto Single Cavity Blocks: Tailored Construction Solutions

Semi automatic single cavity block making machines require some manual intervention during the production process. While the mixing, compression, and ejection of the blocks are automated, the loading of raw materials, operation of the machine, and removal of the cured blocks from the mould are typically done manually.

These machines are suitable for small to medium-scale block production, offering a cost-effective and efficient solution for manufacturing concrete or cement blocks used in construction projects or for producing specialized blocks with specific designs.

Applications of Single Cavity Bock Making Machine (Semi-Automatic)

A semi-automatic single cavity block making machine has various uses in construction and related industries. Some of the common applications and uses of such a machine are:

- Construction projects : The primary use of block making machines is in construction projects to produce concrete or cement blocks for building walls, partitions, foundations, and other structural elements. These blocks are widely used in residential, commercial, and industrial construction.

- Retaining walls : Blocks produced by these machines can be used to build retaining walls, which are structures designed to hold back soil or other materials. Retaining walls provide stability and prevent erosion, making them essential for landscaping and engineering projects.

- Retaining walls: Blocks produced by these machines can be used to build retaining walls, which are structures designed to hold back soil or other materials. Retaining walls provide stability and prevent erosion, making them essential for landscaping and engineering projects.

- Border walls and fences: The uniform and sturdy blocks produced by the machine can be used to construct border walls and fences around residential, commercial, or institutional properties. These walls provide security, privacy, and demarcation of boundaries.

- Decorative elements: The versatility of block making machines allows for the creation of blocks with decorative patterns and designs. These blocks can be used as decorative elements in buildings, adding visual interest and architectural flair.

- Decorative elements: The versatility of block making machines allows for the creation of blocks with decorative patterns and designs. These blocks can be used as decorative elements in buildings, adding visual interest and architectural flair.

- DIY projects: Individuals and hobbyists interested in creating their own blocks for personal projects can benefit from a semi-automatic single cavity block making machine. It allows them to produce blocks according to their specific requirements, such as for garden projects, small-scale constructions, or crafts.

Functions of Single Cavity Block Making Machine (Semi-Automatic)

The functions of a semi automatic single cavity block making machine involve several steps and operations to produce concrete or cement blocks. Here are the main functions performed by the machine:

- Raw material loading: The operator loads the required raw materials, such as cement, sand, aggregates, and water, into the hopper of the machine. The materials are usually pre-measured to ensure the proper mix ratio.

- Mixing: The machine starts the mixing process, where the raw materials are combined in the mixing chamber. The mixing mechanism, such as blades or paddles, thoroughly blends the materials to achieve a homogeneous mixture.

- Block moulding: Once the mixing process is complete, the operator transfers the mixed material from the mixing chamber to the mould. The mould is positioned beneath the mixing chamber, and the material is poured into it.

- Vibration and compaction: After the material is placed in the mould, a vibrating table or platform is activated. The vibration helps to settle and compact the material evenly within the mould, eliminating air pockets and ensuring proper density and strength of the block.

- Compression : A hydraulic or manual pressure system applies pressure to the material within the mould. This compression process further enhances the block's density and strength. The pressure system may be operated manually or automatically, depending on the machine's design.

- Curing : The compressed block remains in the mould for a specific period to allow the material to set and gain sufficient strength. The curing time can vary depending on the type of material used and the desired block characteristics.

- Block ejection : After the curing period, the ejection mechanism is activated to release the block from the mould. This can be done manually or through a mechanical or hydraulic system, depending on the machine's design.

- Block handling : Once the block is ejected from the mould, it is typically manually removed from the machine and placed on a curing rack or pallet for further curing and drying. The operator repeats the process to produce additional blocks.

- Control and operation : The machine may have a control panel with buttons or switches that allow the operator to control the various functions and parameters of the machine, such as mixing time, vibration intensity, compression pressure, and ejection timing.

It’s worth noting that while the mixing, compression, and ejection processes are automated in a semi-automatic machine, the loading of raw materials, operation of the machine, and handling of blocks are typically performed manually or with minimal operator intervention.