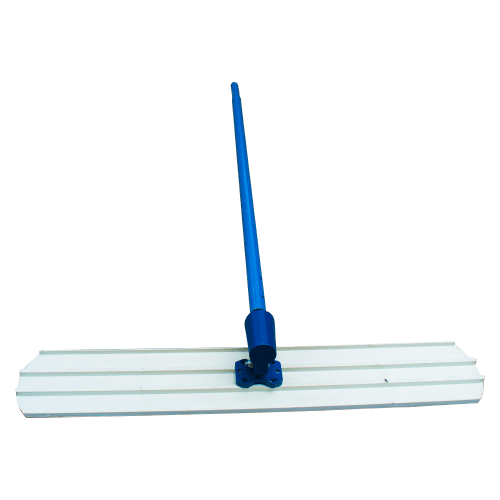

Bull Floater

Bull Floater

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Usage | Finishing Tool For Concrete Road |

Blade Material | Aluminium |

Lenght | 17 feet |

Width | 4 Feet |

What is a Bull Floater?

The bull floater is a spectacular construction equipment piece – its primary purpose is to smoothen a concrete surface using its rectangular-shaped float. The float has a long handle made of magnesium or aluminum. According to industrial standards, the bull floats are typically 8 inches wide and 3 to 10 feet long.

The bull floater comes into play once the concrete undergoes successful screeding. The floater stays at a slight angle as the operator drags it across the concrete surface. This action removes any ridges or imperfections and embeds the coarse aggregate below the surface!

Are you looking to buy a bull-floater? Before making the final purchase, please take a deep breath and go through this article to understand the primary aspects of the bull-floater, its sanctimonious advantages over traditional concrete levelers, and its paramount prominence in the construction industry. All the best!

Table of Contents

What Are the Key Features of the Bull Floater?

When choosing a bull floater, it is crucial to consider its primary aspects so that it can become the ideal choice for your project. A shorter float is the go-to choice for short-term assignments, while larger ones are compatible with long-term endeavors. Also, the quality of the bull floater is a make-or-break factor!

Here are the casual features you will find in most bull floaters:

The traditional size and shape: The ideal measurements of a bull floater hover around 8 inches in width and 3-10 feet in length. It is rectangular and boasts a miniature curve at the front edge, designed primarily to assist the float in gliding smoothly over the surface.

The composition from robust materials: The bull floater has to be a lightweight product because it requires manual labor. Therefore, it is composed of magnesium or aluminum – materials that are light but durable.

The long handle: This handle is long because the operator can stay straight on his feet while using it. Controlling the float becomes much easier, and say goodbye to preemptive fatigue!

The bracket or mounting system: Some sophisticated models boast a mounting system for attaching external accessories. This feature proves handiful when the bull-floater has to reach hard-to-access areas.

Additional features complementing this technical marvel are rounded corners to reduce the risk of marking the concrete surface, extruded ribs to strengthen the float, adjustable handles to prioritize comfort, and a quick-release pin to easily attach the handle and vice versa!

How Does the Bull Floater Work?

The bull floater follows a pretty straightforward process to flatten concrete areas, and the industry’s veterans have gained a knack for producing high-quality surfaces with its assistance.

To use a bull floater, the user must learn to hold it at a slight angle first. Next, once the ideal holding structure materializes, the surface must witness long, dragging strokes over it in a smooth flow.

Remember that the float’s angle will always depend on how much-unwanted material needs extraction from the surface. Steeper slants do a great job of removing deeper materials, while shallower angles will only graze the surface.

As the bull floater gets dragged across the concrete, one can notice the elimination of all ridges or imperfections over the surface. Also, the process helps in embedding the coarse aggregate below the surface, which can epitomize robust and more durable finishes.

If you did not understand how the bull-floater works, here’s a listicle underlining each step. Don’t worry; we have you covered!

- First, make sure the concrete is at the right stage for floating. It should be firm enough to carry the weight of the bull floater but not hard enough that the whole process becomes difficult to carry out!

- Second, hold the float at a slight inclination and drag it across the surface in a long, smooth motion.

- Third, overlap each stroke by about one-third to ensure sufficient coverage across the entire surface.

- Fourth, stay alert! Too much overworking on the concrete can have a negative impact as it can weaken the finish.Is this your first time using a bull floater? A wise idea would be to practice its efficiency in a smaller area before applying it to a larger project. It only takes a little practice to produce professional-looking results!

The bull-floater follows a pretty straightforward process to flatten concrete areas, and the industry’s veterans have gained a knack for producing high-quality surfaces with its assistance.

To use a bull floater, the user must learn to hold it at a slight angle first. Next, once the ideal holding structure materializes, the surface must witness long, dragging strokes over it in a smooth flow.

Remember that the float’s angle will always depend on how much-unwanted material needs extraction from the surface. Steeper slants do a great job of removing deeper materials, while shallower angles will only graze the surface.

As the bull-floater gets dragged across the concrete, one can notice the elimination of all ridges or imperfections over the surface. Also, the process helps in embedding the coarse aggregate below the surface, which can epitomize robust and more durable finishes.

If you did not understand how the bull-floater works, here’s a listicle underlining each step. Don’t worry; we have you covered!

- First, make sure the concrete is at the right stage for floating. It should be firm enough to carry the weight of the bull floater but not hard enough that the whole process becomes difficult to carry out!

- Second, hold the float at a slight inclination and drag it across the surface in a long, smooth motion.

- Third, overlap each stroke by about one-third to ensure sufficient coverage across the entire surface.

- Fourth, stay alert! Too much overworking on the concrete can have a negative impact as it can weaken the finish.

Is this your first time using a bull floater? A wise idea would be to practice its efficiency in a smaller area before applying it to a larger project. It only takes a little practice to produce professional-looking results!

Where is the Bull Floater Applicable?

The bull-floater is a critically proficient asset to the construction industry. It is conveniently applicable across several projects and has carved its legacy out to stay relevant in the construction industry for many years.

Here’s a short list stressing the usage-case scenarios of the bull floater:

Sidewalks: Sidewalks need even flooring to facilitate cozy movement for pedestrians.

Patios and driveways: Patios need smooth floors to align with aesthetic comfort, while driveways need even paths to allow the ongoing flow of vehicles.

Floors: Who does not want beautiful floors? The bull floater makes great floors for all kinds of spaces, from residential to commercial and private.

Slabs: Integrated slabs in walls or flooring alleviate the visual beauty of an architectural environment.

Countertops: The kitchen is superb for showing off your culinary skills! It’s also the ideal location to exhibit your interior artistry, as smooth countertops make for great cooking platforms.

Fireplace hearths: Beautifully curated fireplaces bring warmth and luminosity to winter-oriented homes and breathe a satisfactory sense of life into interiors.

Swimming pools: Imagine standing on an uneven pool bed! Swimming pools are state-of-the-art attractions for personal and public spaces, so their surroundings must be polished and aesthetically pleasing.

Other applicable areas where the bull floater comes into aggressive play are making smooth decks, convenient parking lots, perfectly laid out roads and bridges, etc.

What Are the Advantages of the Bull Floater?

A bull floater exhibits many advantages in the construction industry as it is the perfect choice for carrying out specific work other traditional surface flatters may not excel at.

Here are the most crucial benefits it brings into the discussion, effectively propelling it into prime status:

It creates smooth and level surfaces: If your desired space has noticeable imperfections, expect the bull floater to resolve that! Smooth and even finishes complement its repertoire, while you can also expect visual fidelity and durability.

It embeds coarse aggregate below the surface: The bull-floater additionally assists in embedding coarse aggregate below the concrete’s surface.

It removes excess water from the concrete’s surface: If a surface area is unstable and abundant with water, it can make the concrete weak. Therefore, the bull floater eliminates this dilemma by removing the unwanted water level, which can prevent the concrete from future cracking and chipping.

It is applicable for both large and small concrete surfaces: The bull floater is a compatible device; expect its applied efficiency on wide sidewalks and driveways to small countertops and fireplace hearths.

It is relatively easy to use: Even beginners can excel in handling the bull floater! Practice is the key to unlocking the tool that exhibits the product’s finer characteristics.

Have your next project started screaming for the presence of a bull floater? Are you looking to use one for your next assignment? Or perhaps you forgot to buy the bull floater before starting your project and happen to need one at the most immediate moment?

We have all the answers to your most complicated solutions!

Lotus Traders keeps stock of the finest bull floater models and has additional construction-related equipment like brick-making machines, earth compactors, vibrators, vacuum dewatering pumps, etc. Whatever the product you need for your construction endeavors, we own it. And believe us, we have the finest of the lot!

Feel free to drop by our shop today for a more intimate experience!

Concrete Mixer Machine With Lift

Manual 4 Cavity Brick Machine

Egg Laying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator