Home > Vibrator Machines

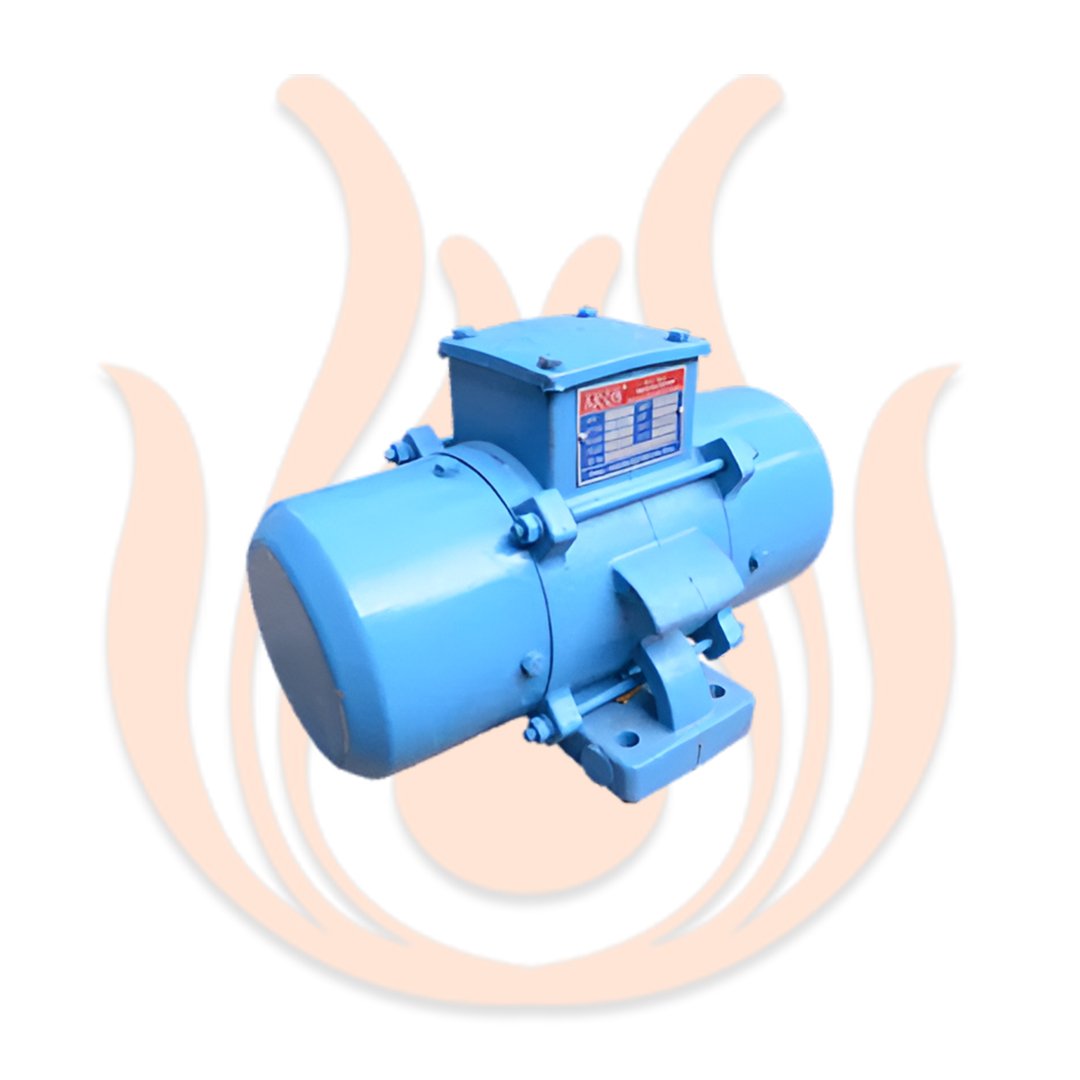

VIBRATOR MACHINES

Vibrator machines used in construction are equipment that generate vibrations to help compact materials like concrete or soil. In concrete work, they are often attached to form work or used directly in wet concrete to remove air bubbles and ensure a solid, smooth finish. This process helps improve the strength and durability of the concrete. In soil compaction, vibrators are used to settle and compact the ground, making it more stable for construction. These machines are essential for ensuring quality and structural integrity in construction projects.

Requirements-

The requirements for vibrator machines used in construction typically focus on the following aspects:

Power and Efficiency:

- Vibrator machines must have sufficient power to generate the required vibration intensity to compact concrete effectively. The machine should operate efficiently, ensuring consistent results across large volumes of concrete.

Vibration Frequency and Amplitude:

- The vibrator must offer adjustable frequency and amplitude settings, allowing the operator to fine-tune the vibration based on the type of concrete and the specific task.

Durability and Strength:

- Since construction sites are harsh environments, the vibrator machine must be made of durable materials that can withstand rough handling, exposure to weather conditions, and the wear-and-tear of continuous use.

Ease of Operation:

- The machine should be easy to operate, with simple controls for adjusting vibration settings. This ensures productivity and reduces the risk of errors during the compaction process.

Portability and Mobility:

- Depending on the type of work, the vibrator should be portable and easy to move across the site. Compact designs are important for easy transportation and accessibility in tight spaces.

Safety Features:

- Safety mechanisms such as overload protection, automatic shut-off features, and ergonomic handles are essential to prevent accidents and ensure the safety of the operator during use.

Noise Reduction:

- Construction sites can be noisy, so the vibrator machine should operate as quietly as possible to reduce noise pollution, especially in urban areas.

Maintenance and Longevity:

- The machine should be easy to maintain, with readily available replacement parts. Regular maintenance should be manageable to ensure the vibrator has a long operational life.

Compatibility with Concrete Forms:

- The vibrator should be compatible with the specific types of concrete forms used in the project, whether internal, external, or surface vibrators are required.