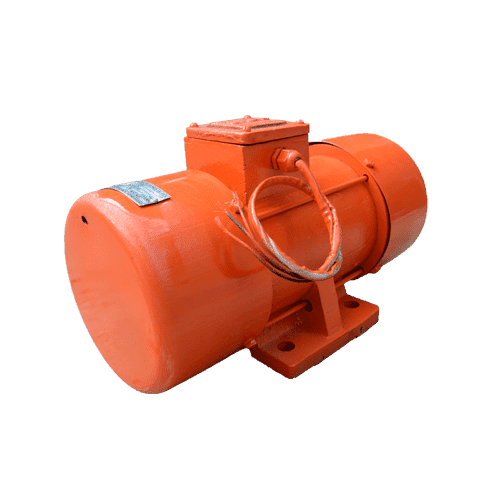

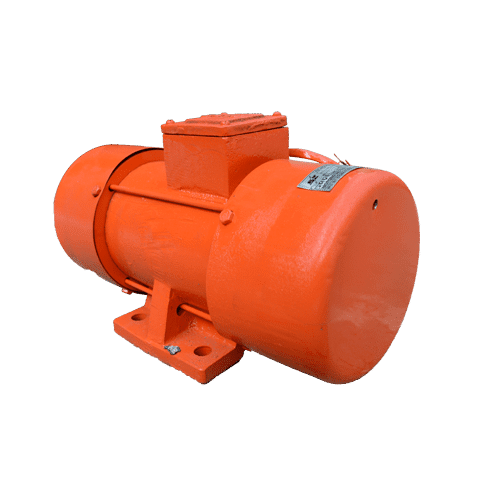

3 Phase Vibrator Motor

- High Quality Materieals

- Compliance with Standards

- Clear product information

- Warranty & Supports

- Product testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

What is 3 phase vibrator motor ?

The 3 phase vibrator motor is an electric motor used in most heavy-duty vibrators on the principle of a three-phase system. This driving mechanism is responsible for making several applications better in a lot of industries ranging from automotive devices to consumer electronics.

In our industry, there are three sinusoidal voltages that impact with the motor, thereby creating a rotating magnetic field that drives the motor’s motion. Vibratory feeders, conveyors, sieves, and a host of other devices depend on the 3 phase vibrator motor to provide controlled vibration.

Table of Contents

What Are the Key Features of 3 phase vibrator motor ?

There is a lot of features to choose from when we discuss about the efficiency of a 3 phase vibrator motor. This mechanical component stands out for a set of striking characteristics or specifications, such as:

The 3 Phase Operation: Compared to single phase vibration motors, this one operates on a three phase electrical system, which leads to a more even distribution of power. This leads to smooth and more resilient operations.

The Rotating Magnetic Field: This field is responsible for generating the mechanical vibrations, and for driving the motion of the motor.

The Variable Speed and Control: Having different options to choose when it comes to selecting vibration frequencies is very important in concrete compaction. Depending on the project requirements, the 3 phase vibrator motor accommodates for this feature.

The High Frequency: This is the ultimate motor for high efficiency and power factor. It is more energy-efficient, thereby branding itself as the industrial option in applications demanding high energy consumption.

The Smooth Operation: The power output of the 3 phase vibrator motor does not mean that it is complex to operate; in fact, it is a handy mechanism that reduces vibrations and noise. This is a handy feature for running the motor in sensitive environments.

The Reliability: Due to the heavy-duty nature of the motor, manufacturers make them harder to break down compared to their single-phase counterparts. Thus, demanding industrial environments can continue their work without worrying about the motor’s durability.

Today, the 3 phase vibrator motor has found prominence in various industries, from manufacturing to electronics and many more. Its longer service life and reduced downtime are a few additional features we will conclude with for describing the product.

How Does the 3 phase vibrator motor Work?

There is physics involved in the working procedure of the 3 phase vibrator motor, as it is a highly technical device capable of delivering unparalleled vibration frequencies. The Lotus team has simplified by procedure by preparing a how-to list for the reader’s convenience:

- First, operator connect the motor to a three phase power supply, typically three sinusoidal voltages that are 120 degrees out of phase with each other.

- Once the motor receives the power, it generates a rotating magnetic field, which causes the three phase currents to flow through the stator windings.

- Once the rotor experiences the influence of the magnetic field, it instantly generates a mechanical force, thereby causing the motor to rotate at once.

- When the eccentric mass on the rotor creates an unbalanced force, it moves in response to the magnetic field, which further generates the required vibrations.

- These vibrations travel to the connect load or the equipment such as a vibrator, conveyor, feeder, or sieve.

It is possible to change the vibration frequency of the motor according to the required measurements. This comes in handy for compacting and consolidating concrete mixes of various specifications across large-scale industrial operations.

What are the Application of 3 phase vibrator motor ?

It is worth noting that while the single phase vibration motor is mostly ideal for concrete compaction, the 3 phase vibrator motor has other additional duties top. Besides enhancing the integrity of freshly laid concrete by removing entrapped air bubbles within the concrete mix, it is useful for:

Vibratory Feeders: Vibratory feeder systems use the motor to convey and transport bulk materials or components. The controlled vibrations from the 3 phase vibrator motor helps in smoothening out such complex tasks.

Conveyors: Conveyor depend on the motor to provide efficiency in material handling systems for efficient and stable transportation of goods. The vibrations aid in preventing material blockages and ensures a steady flow.

Screening and Separation Equipment: Based on the size of different particles, the 3 phase vibrator motor helps these kinds of equipment by sorting and classifying materials through different mesh sizes.

Compactors and Shakers: Concrete or bulk solid require proper setting and compacting. The 3 phase vibrator motor helps contractors in completing this task.

Foundry Equipment: Shakeouts and casting coolers use the motor to separate sand from castings. It helps in efficiently breaking up sand molds and streamlining the casting removal process.

Concrete Block Machines: There is another use for the motor in the construction industry, as it helps concrete block machines to compact and shape different concrete mixtures during the important block-forming process.

Some other applicable scenarios we can think about the 3 phase vibration motor are its inclusion in industrial hoppers and bins, testing and measurement devices, automotive applications like seat vibrators, and medical devices like sensitive therapy equipment.

What are the Advantages of 3 phase vibrator motor ?

It is impossible to imagine a technologically driven world without the inclusion of the 3 phase vibrator motor in most systems. Its advantages line up one after another to complement its existence, with efficiency and smooth operation standing upfront as two of the most important factors propelling it to legendary status.

It additionally offers precise speed control, which means the motor can simply adjust with different vibration amplitudes if the situation demands, thereby always providing optimal performance. And compared to single phase motors, this product is not here to fool around; it will provide power for the most complex industrial operations.

Finally, we need to mention how durable and reliable the 3 phase vibrator motor is, and it can live a longer service life with lower maintenance requirements. If reduced heating and improved torque characteristics rank on top of your list, you can do no wrong by opting for a 3 phase vibrator motor.

Why Buy From Lotus Traders?

Planning to own a 3 phase vibrator motor soon? The offerings from Lotus Traders are an industrially preferred choice, with our products guaranteed to offer with many years of relentless service.

Judging by the current market statistics, our research team is certain that a 2800 RPM 3 phase vibrator motor will have a price tag of Rs. 8500, but if you want to settle for a 180 Watt reversible motor, it will charge Rs. 6000 per unit. There are higher priced alternatives as well, such as the three phase 1440 gear motor settling for about Rs. 12, 500.

Since different motors reflect different prices, you would do well to consult industrial experts before settling for a certain model. Contact us today to own a perfect 3 phase vibrator motor that aligns with your needs.

Frequently Asked Questions

The three phase vibration motor is an electric motor installed in most heavy-duty vibrators on the principle of a three phase system. This driving mechanism is responsible for making several applications better in a lot of industries ranging from automotive devices to consumer electronics. In our construction industry, there are three sinusoidal voltages that impact with the motor, thereby creating a rotating magnetic field that drives the motor’s motion. Vibratory feeders, conveyors, sieves, and a host of other devices depend on the three phase vibration motor to provide controlled vibration.

The 3 phase vibration motor HSN code is 85015110.

If you are looking to own the best 3 phase vibration motor at the most affordable price, contact Lotus Traders today to get a quote on the specific product.

The 3 basic types of three phase vibration motor are plain or squirrel cage induction motors, double squirrel cage motors, and wound-rotor or slip-ring induction motors.

A vibration motor falls under the category of ERM (Eccentric Rotating Mass) vibration motors. They consist of a cylindrical form factor in which the mass and rotating shaft stays exposed.

The different types of vibration mechanisms are crank mechanisms, unbalanced mass, electromagnetic inductions, and pneumatic or hydraulic operations.

The best 3 phase vibration motor price will depend on your region, but to maintain the integrity of the market, we can predict that a top-quality 3 phase vibration motor will cost somewhere between Rs. 8500 and Rs. 12, 500.

The 3-phase induction motor identifies by this term because it derives its rotor current from a magnetic field instead of electrical connections. It operates under the principle of a rotating magnetic field.