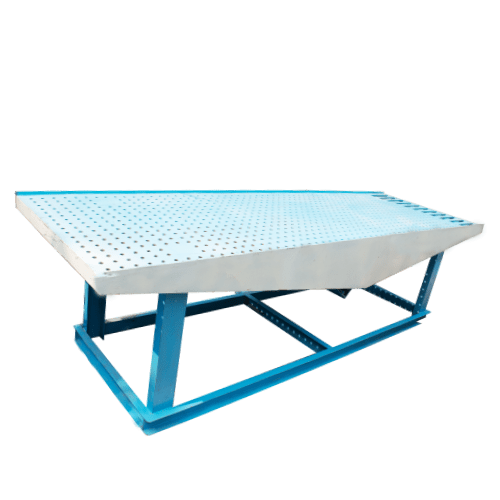

Vibro Forming Table

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Total Power | 2.34 kw / 440 Volt |

Vibrating Plate Thickness | 10 mm |

Vibrating Table Size | 3000mm x 750mm |

manufactured | Made in India |

What is Vibro Forming Table?

A vibro forming table is a type of table that causes vibrations. It is also known as vibrating table or vibration table. These are the machines which is used in various industries like construction and manufacturing, it is used to settle or combine materials like concrete, cement and moulds. Vibro forming table reduces the amount of additional water and air bubbles from these materials and increase uniformity in consistency.

Vibro forming tables are widely used not only in the production of concrete products such as bricks, blocks and packaging materials but also in the production of various cast products where uniform density and low porosity are important. Use vibrating tables to increase the strength and durability of your components by eliminating weak points and maintaining construction consistency.

Table of Contents

Features of Vibro Forming Table:

Here are some key features of vibro forming table:

- Vibrating mechanism - The vibrating table is the heart of the machine which produces vibrations that compress the material .Both deviated and linear vibration mechanisms are possible. Deviated vibrators are more popular and have higher vibration frequencies and it is also ideal for solidifying materials at high speeds. Linear vibrators have a lower vibration frequency but can achieve more uniform stability.

- Mould -The mold is the part of the machine that gives the product its final shape. Molds can be made of a various materials such as steel, aluminum, rubber etc. The material of the mold depends on the type of material being processed and the desired end product.

- Vibration table surface - The surface of the vibration table is the part of the machine on which the mold is installed. The surface of a vibration table is usually made of a smooth, non-porous material like stainless steel or acrylic. It prevents the material from sticking to the table surface.

- Vibration table surface - The surface of the vibration table is the part of the machine on which the mold is installed. The surface of a vibration table is usually made of a smooth, non-porous material like stainless steel or acrylic. It prevents the material from sticking to the table surface.

Uses of Vibro Forming Table

Here are some uses of vibro forming table:

- Concrete Product Design - Vibro forming table is commonly used in the manufacture of concrete products such as pavers, tiles and cement. It helps in compacting the cement mixture, package, promoting uniformity and reducing the possibility of errors.

- Precast Concrete Elements - For the manufacturing of precast concrete elements like panels, columns, and beams, vibro forming tables are employed to achieve the desired strength and surface finish. The vibrations aid in consolidating the concrete mix, eliminating voids and improving structural integrity.

- Casting and molding -In various forms of molding and casting, including those used in art and commerce and vibro formed tables. It is used to remove air bubbles, fill and coat mud, detailed and intricate shapes with small imperfections.

- Plaster and Gypsum Products - In the production of plaster and gypsum-based products such as decorative wall panels, ceiling tiles and architectural elements, vibro forming tables are used to ensure a smooth and uniform surface finish.

- Brick Making - Vibratory molding tables are used in the brick industry to compact and form clay or concrete mixtures into bricks, resulting in uniform size and density.

- Rubber and Plastic Products - Vibrating tables are used in the production of rubber and plastic products such as mattresses, automotive parts and gaskets to remove air bubbles and improve material distribution in the mold.

- Pottery and earthenware - In pottery and earthenware, these tables are used to hold clay and smooth materials in shape and help achieve the desired shape and density.

- Food Industry - In the food industry, vibrating tables can be used for tasks such as compressing materials in the manufacture of candy, chocolate and some types of sweets.

Benefits of Vibro Forming Table:

Vibro Forming tables are a unique and versatile tool for concrete production. Some of the key advantage of using vibro forming table are:

- Improve quality product - Eliminate vibrating injection table air bubbles and compacted materials such as concrete,cement and form work.This improves product quality more and more defects such as cracks and surface imperfections.

- Increased strength and stiffness - Uniform compaction throughout vibro forming increases the density and strength of the material, especially concrete. It’s a product that’s more than enough durable and resistant to stress and environmental conditions.

- Consistency - Vibro forming ensures uniform density and distribution of the material throughout the product. This is very important in industries where uniformity is important for structural and aesthetic reasons.

- Increased production speed - The vibrating table reduces the time required for settling and compaction, speeding up the production process. This can improve production efficiency and productivity.

- Reduced material waste - Improved compaction with vibratory forming tables minimizes defects, reduces material waste and improves raw material utilization

- Reduce manual steps - Vibro Forming tables allow us to control the production process and reduce the need for manual labor and repetitive tasks, increasing process safety and employee satisfaction.

How the Vibro Forming Tables work?

A vibro forming table is a type of table that causes vibrations. It is also known as vibrating table or vibration table. These are the machines which is used in various industries like construction and manufacturing, it is used to settle or combine materials like concrete, cement and molds. Vibro forming table reduces the amount of additional water and air bubbles from these materials and increase uniformity in consistency. The following steps describe how a vibro forming table woks:

- Before putting the table into use, make a mold or form with the material to be pressed. You can also make a mold for making cement blocks, stones and concrete tiles or for casting different materials.

- Place the shape or form on the vibrating table.

- Vibration helps remove air bubbles. Makes the mixture evenly distributed and concentrated.

- Once the material is crushed, it is usually left on a vibrating table to dry or cure, depending on the material used. This is important for concrete or cement products.

What makes Vibro Forming Tables Unique?

Vibro Forming tables are a unique and versatile tool for concrete production. They offer a number of advantages over other methods which makes them unique such as:

- High quality product - Eliminate vibrating injection table air bubbles and compacted materials such as concrete, cement and form work. This improves product quality more and more defects such as cracks and surface imperfections.

- High production speed -Vibrating machines can produce many important products in a short time. Stirring helps the concrete dissolve faster and the product will harden.

- Low cost - Vibrating tables are easy to manufacture which helps in reducing production cost.

- Increased strength and stiffness - Uniform compaction throughout vibro forming increases the density and strength of the material, especially concrete. It’s a product that’s more than enough durable and resistant to stress and environmental conditions.

- Consistency - Vibro forming ensures uniform density and distribution of the material throughout the product. This is very important in industries where uniformity is important for structural and aesthetic reasons.

Vibro Forming tables are a unique and adaptable tool for concrete production. A vibro forming table is a type of table that causes vibrations .These are the machines which is used in various industries like construction and manufacturing ,it is used to settle or combine materials like concrete, cement and molds.It offers number of advantages over other manufacturers such as high production speed, high quality materials, low labor costs and adaptable. It is the easiest way from which we can make concrete.

These tables can be used to create a various types of concrete objects such as stone, bricks, tiles etc. They are also used to create complex shapes that are difficult to create by hands. These tables are ideal for any cement manufacturer who wants to produce a quality product at a reasonable price.

If you are looking for a versatile and efficient way to produce concrete products then vibro forming tables are a good option to consider.

Frequently Asked Questions

Some factors to consider while buying the vibro forming tables are:

- Think about your productivity needs. This includes size and the material or amount of material that the machine can handle.

- Find a device that allows you to adjust vibration settings. Add density configure inventory and frequency to meet your requirements.

- Choose appliances made of quality materials and construction. The manufacturing process guarantees long-term durability and performance The machine has a simple structure and is easy to use like inspection and minimum maintenance requirements.

- Make sure the equipment has safety features, such as emergency lighting, stop button and bumper. Ensuring the safety of employees and worker.

Here are reasons why you should want to buy a vibro forming table:

- Vibrating machines can produce many important products in a short time. Stirring helps the concrete dissolve faster and the product will harden.

- These tables provides high quality products with low craftsmanship and high quality. This is because vibrations help to increase the material’s strength by reducing air bubbles in the material.

- Vibrating plates are easy to manufacture which helps in reducing production cost. Unlike other techniques, hand throwing is dynamic.

- They can be used to make a variety of products such as blocks, bricks, boxes, etc. This makes it a useful tool in car manufacturing.

- Vibrating tables are made of durable materials such as steel and concrete, so they last for a long time.

The advantages of using vibro forming tables are:

- Eliminate vibrating injection table air bubbles and compacted materials such as concrete, cement and form This improves product quality more and more defects such as cracks and surface imperfections.

- Uniform compaction throughout vibro forming increases the density and strength of the material, especially concrete. It’s a product that’s more than enough durable and resistant to stress and environmental conditions.

- Vibro forming ensures uniform density and distribution of the material throughout the product. This is very important in industries where uniformity is important for structural and aesthetic reasons.

- The vibrating table reduces the time required for settling and compaction, speeding up the production process. This can improve production efficiency and

- Improved compaction with vibratory forming tables minimizes defects, reduces material waste and improves raw material utilization.

- Vibro Forming tables allow us to control the production process and reduce the need for manual labor and repetitive tasks, increasing process safety and employee

Yes, The vibro forming tables are customized for a specific application and product requirements. Flexibility is a very useful feature of these machines as it allows them to adapt to different materials, shapes, forms and sizes.

Concrete Mixer Machine With Lift

Manual 4 Cavity Brick Machine

Egg Laying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator