Thickness Gauge Longitude

- High Quality Materials

- Compliance With Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- Follow

What is thickness gauge?

The thickness gauge is an integral tool for measuring an aggregate material’s thickness. It falls under the non-destructive testing (NDT) category, compared to traditional tools like the Aggregate Impact Value Apparatus and the Los Angeles Abrasion Testing Machine, which depend on destroying the aggregate’s component by applying force to it.

The thickness gauge for aggregate uses a British Standard classification system to determine the flakiness index of an aggregate sample. Low flakiness means the aggregate is good!

The thickness gauge is not only prevalent in the construction industry but is also useful to manufacturing and quality control. You will come across many models for different applications, and the most common types include:

- Feeler gauges that contain blades

- Micrometers that has a screw mechanism to measure distance

- Ultrasonic thickness gauges that use sound waves

Magnetic thickness gauges to measure the thickness of non-magnetic materials

Table of Contents

What Are the Key Features of the thickness gauge?

The efficiency of a particular thickness gauge depends upon the type of situation it is applicable for. There are also external factors like the material in need of measurement, the accuracy, and the provided budget. We aim to provide you with a few areas where the thickness gauge has very important working principles!

We have explained the primary features of the thickness gauge in a simple list below:

- First, it gives a suitable measurement range to accommodate the aggregate material’s expected thickness.

- Second, it is highly accurate, which is a necessary feature to ensure measurements do not go wrong.

- Third, most of its models have a clear and convenient display for interpreting measurement results.

- Fourth, it boasts a unique probe or sensor that comes into contact with the aggregate’s surface when measuring its thickness.

- Fifth, the thickness gauge is also easy to calibrate; a necessary step for maintaining constant accuracy.

- Finally, it provides users with data logging capabilities for further record-keeping and analysis purposes!

While most models are relatively similar, the specific features of an aggregate thickness gauge vary on several factors such as the manufacturer, model, and intended use.

How Does the thickness gauge Work?

Yes, the thickness gauge for aggregate plays a dominating role in the construction industry by determining the aggregate’s flakiness index. If an aggregate particle is flaky, it means it will break down quickly over time. So, it is crucial to use aggregates that have a low flakiness index ratio!

Using the thickness gauge for aggregate is easy, something we aim to explain in simple steps below:

- First, separate the aggregate sample into seven sieve fractions, starting from 6.3 mm to 63 mm.

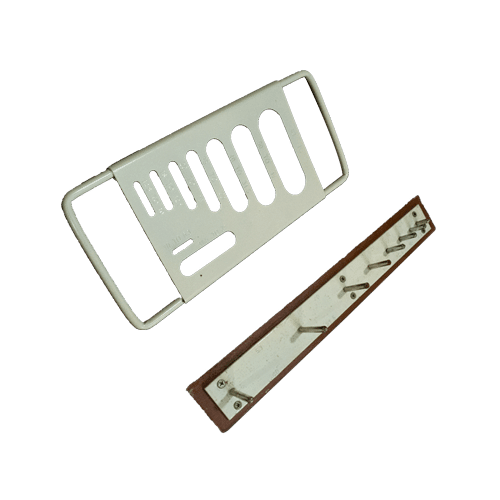

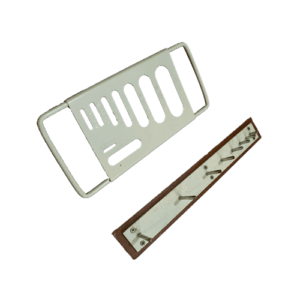

- Second, place each fraction into each separate slot inside the thickness gauge.

- Third, slide the panel of the gauge down until the particles are barely touching the bottom surfaces of the slots.

- Fourth, it is time to weigh the amount of aggregate articles that pass through each slot!

- Fifth, derive the flakiness for each fraction using the following formula:

Flakiness index = (weight of aggregate particles passing through slot) / (total weight of aggregate sample) x 100%

When you calculate the average flakiness index across all the sieve fractions, you finally get the overall percentage describing the entire flakiness of the aggregate sample. Most construction projects accept that if the flakiness index is over 25 percent, the aggregate sample is faulty and not fit for use.

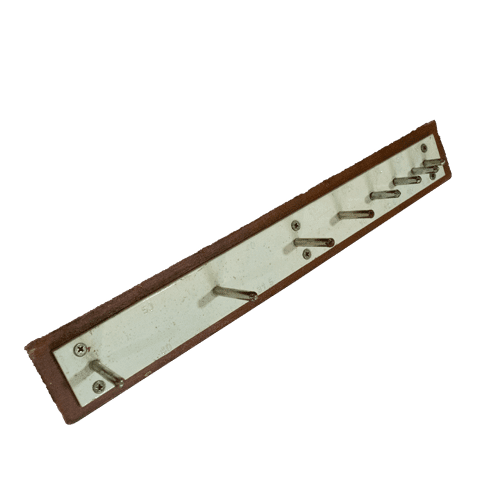

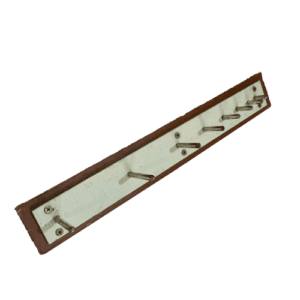

This particular tool is paramount to remove the inconsistency in such situations, by constantly evaluating aggregate samples and the ones that ensure high quality. A thickness gauge for aggregate has a frame with a sliding panel. This sliding panel has slots of standard width and length. These slots store the aggregate particles where experts measure their thickness. Finally, the flakiness index originates as a percentage of the aggregate sample’s total weight.

What are the Application of the thickness gauge ?

Some of the most ideal applications for the thickness gauge are:

- Quality Control: Quality control is a crucial part of the manufacturing process to ensure customer satisfaction. Food packaging, pharmaceutical products, and medical equipment depend on this process to keep their product standards high.

- Safety Standards: Different day-to-day city parts like pipelines, pressure vessels, and storage tanks need the thickness gauge to measure their thickness because of the importance of safety. Sudden bursts can lead to major unwanted accidents!

- Research and Development: The tool is useful for measuring the thickness of fresh materials and coating that are currently under development.

- Process Control: During manufacturing and other processes, a thickness gauge can determine if the thickness of each specific material is consistent enough to go to the market.

- Maintenance and Inspection: The gauge can also find out if a material has suffered from corrosion, erosion, or other damage! It becomes easier to remedy potential problems before they cause any failures.

Some examples that describe the use of a thickness gauge are measuring the thickness of paint applied on a car, measuring a pipeline wall to identify thinning issues, measuring a paper coating’s thickness to meet quality standards, etc.

What are the Advantages of the thickness gauge ?

A thickness gauge offers a host of benefits over other aggregate testing methods, about which we will explain in simple terms.

First, this is a non-destructive testing method. This is important in situations where preserving the material’s integrity is a project requirement. It also has a user-friendly interface for allowing easy operation. Fancy models offer connectivity options to transfer data to a computer for further analysis.

More conventional features of the thickness gauge include its compactness, which makes it a lightweight tool fit for constant portability. This does not mean the gauge has a thin build quality! It comprises of materials that must withstand moisture, dust, and rugged environments.

Finally, most models comply with industrial standards and certification from relevant authorities. Therefore, expect supreme consistency in results from the thickness gauge

Why Buy From Lotus Traders?

Lotus Traders has enjoyed a prominent market reputation in the construction industry for over fourteen years. We have delivered top-quality products all around the North East section of India without any delay and have strived to meet the ever-changing needs of our loyal customers.

For general estimates, you can consider a traditional thickness gauge for aggregate to cost around Rs. 450, and a flakiness gauge will come around the same price range. A flakiness and elongation gauge will however, have a price tag of Rs. 225, while higher variants like an ISI marked flakiness gauge will cost you upwards of Rs. 2,500! If you want an accurate price range that determine how much you have to spend on a particular thickness gauge, expect a general value starting from Rs. 200 to rounding out at Rs. 5000.

Please note that while these numbers reflect the current prices in the market, they constantly change due to several reasons like fluctuation, availability and demand. There is systematic saturation in the current market which brings constant changes to the prices of all products related to construction. If you find something for sale cheaper today, it may be pricier tomorrow!

Therefore, if you happen to need the perfect product to complement your upcoming project, feel free to drop a call on our site number today! Or if you feel like you are one step closer to your purchase, visit our shop in Guwahati to take the final step in owning your ideal thickness gauge

Frequently Asked Questions

The thickness gauge for aggregate is a crucial tool to measure the flakiness index of aggregate samples. Compared to traditional destructive methods for aggregate testing, the thickness gauge actually preserves the sample specimen while performing the test.

The primary principles of the thickness gauge are to provide quality control, maintain safety standards, assist in research and development, maintain the flow of constant process control, and assist in regular inspection.

A thickness check tool identifies as a thickness gauge – a primary component for measuring the thickness of several materials across different industries.

There are no subtle benefits between a digital thickness gauge and an analog thickness gauge; the former displays numbers in values on its information screen while the latter has a round dial like an analog clock. Ultimately, the choice to buy is yours

The best thickness gauge price is difficult to determine due to the product’s availability or other influential factors, but expect a fine quality, traditional thickness gauge to start from Rs. 1000, and higher-end variants crossing over Rs. 5000

Lotus Traders has the best thickness gauge in Guwahati, so if you are looking to buy one for your aggregate sample test, contact us today to take home the perfect model

The primary thickness gauge uses you can avail are for checking the flakiness level of aggregates; checking the packaging thickness of industrial products, maintaining the flow of quality control, and detecting corrosion or erosion in certain materials

The flakiness index gauge is for calculating the flakiness level of an aggregate sample. Industrial standards demand the flakiness level below 25 percent, or else the aggregate is unfit for application

Yes, Lotus Traders has the best thickness gauge models available for sale. If you are in the market looking for one, take the first step by browsing for your ideal product on our site today

Yes! Lotus Traders has the perfect Los Angeles Abrasion Testing Machine you want, so feel free to ask for a quote today!