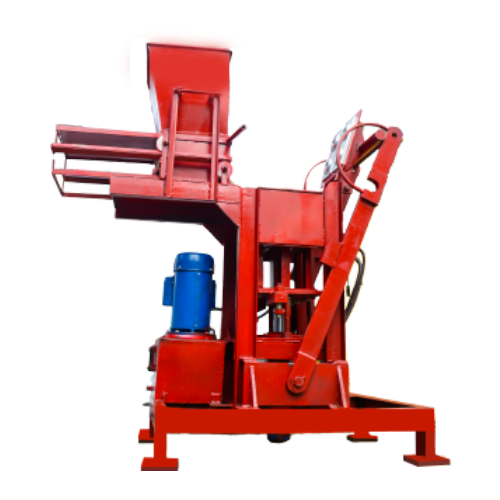

Latest 3Phase,3hp Electric Concrete Mixer Machine | Lotus Traders

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

Electric concrete mixer machine is one of the most popular construction machines. Electric concrete mixer machine are used for mixing concrete. They are also known as concrete mixers. Electric concrete mixer machines are available in different sizes and capacities. important part of the construction industry.

Used for mixing concrete. This machine has many advantages over manual mixers.

FEATURES | SPECIFICATION |

|---|---|

Batch Capacity | 10 cft Unmixed 7 cft Mixed |

Capacity (Lit) | 250 unmixed/ 190 mixed |

Motor | 3ph 3hp electric motor |

What is an Electric Concrete Mixer Machine?

An electric concrete mixer machine is a piece of construction equipment for mixing cement, sand, gravel, and water to create efficient concrete. It is an asset for various construction projects, such as developing foundations, roads, bridges, etc. This machine is a darling in the industry because it is easy to use, relatively portable, and eliminates manual effort to mix the ingredients.

The electric concrete mixer machine plays a fascinating role in the construction industry by offering versatility and indispensability across several projects. It can streamline the concrete mixing process, improve efficiency, and enhance project outcomes without delay or accidents. It’s a rockstar!

Earth is undergoing extensive global warming, and the biggest multinational companies now strive to reduce emissions and greenhouse gases. The electric concrete mixer machine is a child product of such ideologies because, at its core, it aims to sponsor eco-friendly characteristics, reduce noise levels, and align with sustainable construction practices.

Furthermore, the electric concrete mixer machine contributes to cost-effective and reliable construction operations. It is relatively easy to use, demands lower maintenance requirements, and consistently reduces downtime and labor costs. It has become the perfect choice for contractors, DIY enthusiasts, and construction professionals!

Whether utilized for private residential projects or top commercial endeavors, the electric concrete mixer machine stands today as a symbol of efficiency, reliability, and environmental responsibility, embodying the ever-evolving needs and goals of the 21st century’s construction industry!

Table of Contents

Key Features of the Electric Concrete Mixer Machine

Several key features underline the efficiency of the electric concrete mixer machine and make it an undisputable player in the construction market.

First, it runs on electricity and avoids using non-renewable energy sources like petrol or gasoline. The electric motor is connected to a standard electric outlet and is the primary energy source for rotating the drum or mixing container.

Second, the mixing drum is the heart of the electric concrete mixer machine! It has blades or paddles that assist in blending all materials into a fine mix and producing high-quality concrete.

Third, the electric concrete mixer machine has many model variants, so expect different concrete mixing capacities for each model. Some are applicable for DIY home-centric projects, while other variants with large mixing drums are fit for large-scale construction projects. Remember to check the drum’s capacity before investing your money!

Fourth, the electric concrete mixer machine comes on wheels! While it’s no supercar, site operators save precious time and effort with its portability and transportation features.

Fifth, simple control mechanisms elevate the usability of the electric concrete mixer machine. Controls like starting, stopping, and reversing the drum’s rotation make for easy handling of the machine’s operations.

Overall, electric concrete mixers have become the norm in construction because of their capacity to provide consistent, high-quality concrete and reduced manual labor in construction sites. Today’s market offers various designs and sizes, but the key features to operate them are identical.

How Does an Electric Concrete Mixer Work?

The how-to is the most crucial part of understanding how an electric concrete mixer machine works, so attempt not to skip this section!

Let us simplify how this technical marvel works by diving and explaining each step.

First, you need to add the ingredients to the mixing drum. What are those ingredients? They are usually cement, sand, gravel, and water. Remember to add precise quantities, or your concrete mix will be unstable!

Second, turn on the electric motor, which will lend electrical energy to rotating the mixing drum.

Third, once the drum starts rotating, the internal blades or paddles move in a direction to agitate the ingredients. Rotational and gravitational force complements this process as the paddles lift the materials from the drum’s surface and make them fall again, effectively overlapping them on top of each other. Do not turn off the motor until you see a uniform mixture!

Fourth, the most sophisticated variants allow adjustment of the mixing speed. Slower speeds give rise to thorough mixing outputs, while faster speeds compensate for quicker work.

Fifth, personal supervision is necessary! Avoid diverting your attention when the electric concrete mixer machine is on because you must stay alert to watch it form the desired mix. A lapse in concentration can lead to unwanted output quality.

Once you notice the fine mix, stop the electric concrete mixer machine’s motor via the controls on the panel. Tilt the drum forward with a lever to pour the concrete into a wheelbarrow or a bucket. Take the concrete to the desired location!

Finally, clean the mixer to prevent any residual concrete from sticking to its surface. This residue can allow future concrete mixing batches to harden more than necessary!

Usage Scenarios of the Electric Concrete Mixer.

The electric concrete mixer machine is innovative and efficient because it does not stick to one usage-case scenario. Such is its capability that it can deliver concrete across a wide range of projects – from small-scale to industrial endeavors!

They come into clutch when a homeowner wants to pour the foundation for his shed, build small buildings in his garden, and harden his sidewalks, patios, and retaining walls.

But for the government, the electric concrete mixer machine plays a pivotal role in construction projects like building pathways and narrow driveways. It can assist in repairing existing structures, patching concrete surfaces, repairing cracks, and creating custom concrete forms.

Private ventures can use the machine to prepare and pour concrete floors for warehouses, factories, and other facilities. The electric concrete mixer machine also pays dividends in forming concrete garden edging, installing pavers, or building small garden walls.

DIY enthusiasts can use this product to enhance the quality of their homes by giving shape to robust garden borders, installing fence posts, or making decorative stepping stones. Masons can apply the electric concrete mixer machine to lay blocks and other masonry posts. You cannot miss it if you adopt this!

Some areas where the machine shines when compared to other traditional mixers is that it can assist in precast concrete production like concrete blocks, columns, and aesthetic products. They also knock it out of the park in limited noise environments where pollution is a concern.

Advantages of an Electric Concrete Mixer Machine.

Why has the electric concrete mixer machine gained so much prominence in the construction industry, and how does it win the battle of wits and wills against other types of concrete mixers? Let us find out why!

Diesel-powered mixers require large quantities of diesel, and gasoline-powered mixers demand the same levels of gasoline, so one can deduce what electric-powered mixers need to run efficiently. But when electricity contributes to the concrete mixing process, there’s no stopping the concrete mixing process.

First, the electric concrete mixer machine produces zero emissions. Zero! Once you eliminate the release of harmful fumes that can pollute the air, the mixer claims the tag of an eco-friendly product. With greenhouse gases exceeding acceptable levels in the past few years, all brands have started aspiring to create environmentally sustainable products. This emboldened initiative makes the electric concrete mixer machine a pioneer in this regard.

Oh, it also runs quieter than its gasoline or diesel counterparts. Talk about wearing the badge of a reduced carbon footprint!

Second, the electric concrete mixer machine is one of the most convenient products to operate in the construction industry. Forget about fueling or maintaining a separate engine. Ignore the constant need for oil changes, fuel filters, or spark plug replacements. Just take it inside your house and stash it away in your storeroom!

Finally, let’s get back to the fundamentals – the electric concrete mixer machine offers precise speed control of the mixing process, is often built from reliable materials, and is an alluring choice for small to medium projects. They are the practical choice for DIY enthusiasts and limited construction jobs.

What Makes the Electric Concrete Mixer Unique?

The industry does not make products without attaching a USP (Unique Selling Point) factor to every one of them. The electric concrete mixer machine exhibits many USPs to compensate for its brilliance and competency over other mixers.

Environmental friendliness is the number one unique factor because the electric concrete mixer machine inspires and encourages people to make eco-conscious choices inside and outside the construction industry.

Environmentally sensitive areas or locations with strict emission regulations may refuse to work with anything except the electric concrete mixer!

Indoor use is an additional masterstroke because of the machine’s versatility and portability range. Indoor construction projects with limited ventilation cannot use diesel or gasoline-powered alternatives due to the pollutant air they release during operations.

If you have consistent electricity access, why even bother working with other mixers? Regular power will stabilize the mixing process and guarantee a uniform concrete paste!

One unique factor potential customers choose to overlook is that the electric concrete mixer machine is a safe device to operate. They eradicate risks associated with storing and handling flammable fuels like gasoline or diesel. They also exhibit safety features to prevent the motor’s accidental startup.

Before modern concrete mixer machines, traditional models required manual labor and inputting ingredients into a rotating drum with one’s hands. Gone are the days of the old processes, as newer mixers like the electric concrete mixer machine accelerate this process with the help of state-of-the-art technical upgrades.

If you’re looking for a top-quality electric concrete mixer machine in the market, we’ve got the best brands to provide value for your money. If you’re looking for other alternatives, we’ve got reversible concrete mixers, one-bag concrete mixers, color mixers with hoppers, laboratory concrete mixers, etc., and many more.

Visit Lotus Traders today or get a booking done in advance to look at our most innovative construction equipment in the industry!

Watch Video of our Electric Concrete Mixer Machine

Frequently Asked Questions

An electric concrete mixer machine is a cement mixer that runs on electricity. It produces zero emissions and is a better alternative to gasoline or diesel-powered mixers.

The most convenient models can start from Rs. 55,000 to the more sophisticated ones exceeding Rs. 75,000

Yes, Lotus Traders deals in electric concrete mixer machines! Visit our shop today for the finer details!

It works as conveniently as other cement mixers, except that the motor depends on electricity rather than inflammable fuels to rotate the contents of the mixing drum. It’s an eco-friendly product!

Electric concrete mixers suit small to medium-scale construction projects, where time is of the essence and demand for concrete quantity is low. Use it to decorate your garden or your dining space!

Size of electric concrete mixer models varies, so expect a wide capacity ratio of handling concrete batches from 500 to 750 liters.

Yes, compared to traditional mixers, electric concrete mixers are relatively easy to operate, although you still must read the guidelines to have a better idea of smoothly carrying out the concrete mixing process

No, not at all! The electric concrete mixer machine has become necessary for DIY enthusiasts with zero to little industrial experience. It’s a good application for revolutionizing home decor!