Home > Asphalt & Bitumen Testing Equipment

Asphalt & Bitumen Testing Equipment

Asphalt and bitumen testing equipment:

Ensuring quality and durability in every road construction project.

Bitumen and asphalt are used as important components in the development and maintenance of roads, high ways, and other facilities on projects. Comprehensive testing procedures are essential for ensuring the quality, performance, and durability of these materials. Testing equipment for asphalt and bitumen is crucial in determining their specifications and qualities. This information enables engineers and other construction specialists to decide accordingly

Importance of Asphalt and Bitumen Testing:

Quality Assurance: Quality control is necessary for different environmental and load conditions affecting asphalt and bitumen. Testing equipment helps in determining whether the raw materials are of industry standard.

Durability Assessment: The testing equipment test the integrity and longevity of asphalt and coal tar emulsions when subjected to temperature changes, traffic loads, and exposure to wet conditions.

Material Selection: Tests enable engineers to decide on the best asphalt or bitumen mixture for specific projects by considering climatic condition, traffic volume, and pavement design.

Compliance with Standards: Standards and Specifications for Asphalt and Bitumen, Regulatory Agencies, and Industry Bodies. The testing equipment ensures that the set standards are adhered to hence safety and dependability is enhanced.

Essential Tests Conducted:

Asphalt Binder Testing: Tests of viscosity, penetration, softening point, and ductility. These tests are done to assess various properties of the Bitumen being used in Asphalt mixes.

Aggregate Testing: Assesses the physical and mechanical properties of the aggregates used in asphalt (gradation, shapes, and specific gravity).

Mix Design: Engineers determine appropriate asphalt mixtures for various projects by using several tests that consider such parameters as traffic volume, climate, etc.

Performance Testing: Tests various performance parameters to establish how resistant asphalts mixes are to stressing up like rutting, fatigue cracking and thermal cracking.

Key features and benefits of performing asphalt and bitumen test:

Regulatory Compliance: Testing for asphalt and bitumen guarantees that materials meet the standard industry specifications and regulatory requirements. Safety, quality, and law dictate that there be compliance.

Data Analysis: The testing equipment provides important information for engineers and construction professionals to choose wisely regarding materials, mix design and methods of building.

Non-Destructive Testing: There are some testing methods that are not destructive which make it possible to assess the current pavements or roads without damaging them. This is important for maintenance and rehabilitation planning.

Accuracy and Precision: Asphalt and bitumen testing equipment are specifically made to give out reliable and reproducible information, which facilitates informed decisions.

Safety: Safety issues are common when dealing with hot bitumen and asphalt materials, hence testing equipment is usually created to protect the operator.

Efficiency: With modernity comes speed; thus, new equipment allows quicker tests, data gathering processes that save much time and financial capital particularly when it comes to building or constructions projects.

Documentation: Testing procedures result in creation of documentation and records about test results, which become important for quality assurance, management of the projects and compliance reporting.

Research and Development: Research and development make use of testing equipment to innovate and improve asphalt and bitumen materials. It will result in better eco-friendly, robust, and improved upon materials.

Environmental Considerations: The evaluation process might be in form of testing their environmental impacts on asphalt and bituminous materials which would go far in selecting eco-friendly materials that match the set sustainability standards.

Products and services provided by lotus traders in asphalt and bitumen testing field:

Lotus traders is well known for providing top-notch and quality products with great after sales services. Lotus traders is the one stop destination for all your constructional requirements and desires.

Asphalt mixer theoretical density meter: The theoretical density meter is used by an asphalt mixer to find out the theoretical maximum specific gravity (Gmm) of an asphalt mix. It employs vacuum extraction on a heated asphalt sample in order to remove air voids that allow for precise proportioning of mix components and maintaining compliance of quality standards for long lasting and high performing asphalt paving.

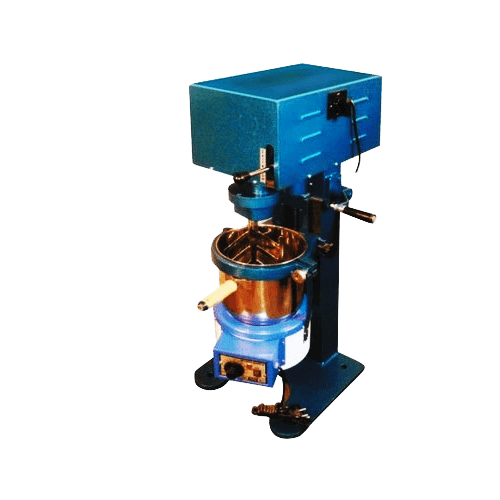

Motorized centrifuge extractor: It is a laboratory equipment which uses electric powered high-speed rotation of a centrifuge to separate asphalt binder out of an asphalt mixture specimen. It comprises a rotating drum driven by a motor into which the sample is loaded. The asphalt-binder is separated from the aggregates by the centrifugal force as the drum turns enabling accurate estimation of the amount of asphalt in it. Asphalt quality control is dependent on this critical piece of equipment, which guarantees that asphalt mixes conform to specified specifications of composition and performance.

Automatic compactor: an automatic compactor is a equipment which compacts materials such as soil, asphalt, or concrete specimens automatically for use in construction sites and civil engineering. This equipment comprises of a motorized mechanism which continually hits the material with hammer or temper to compact it. This procedure stimulates the effect of compaction, ensuring uniform density and consistency in testing.

Automatic Marshall stability machine: this equipment is used for testing asphalt mixture in civil engineering to examine the strength and stability of asphalt mixtures. This machine applies pressure upon a compacted asphalt, then measures its resistance to deformation and cracking under pressure. This device ensures the quality and durability o asphalt materials for road construction, helping engineers to plant and design long-lasting and safe road surfaces.

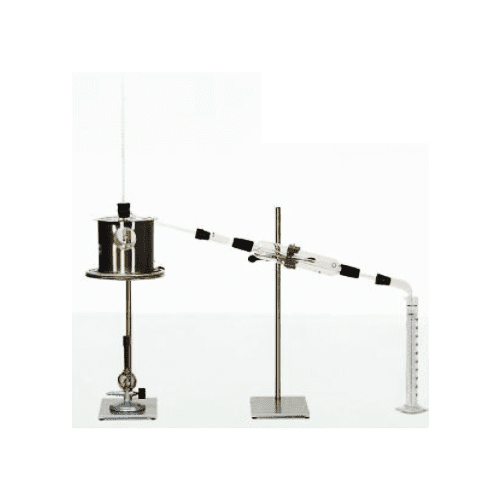

Benkelman beam: The Benkelman Beam – Portable Device for Evaluating Deflection and Rigidity of Pavement Road. The beam has one end placed upon the road surface forming the pivoting point. Engineers determine the structural condition of the pavement by measuring its deflection/flexure with a known load applied. such knowledge is crucial in making roads maintenance and design decision for better and safer transportation infrastructure.

Asphalt content tester: An asphalt content tester is a benchtop laboratory device to measure the percentage of asphalt binder in an asphalt mixture. This process entails evaporating away the lighter constituents of the mix and keeping the asphalt binder. This remaining mass is measured by means of an approved method, so the asphalt content could be important in quality control while constructing or maintaining a road. This information is useful in ensuring that the asphalt mixture meet the desired standards of durability and performance demanded for different infrastructural projects

Hand operated centrifuge extractor: The manual laboratory centrifuge extractor, hand operated, is meant for asphalt testing. The bitumen extract is then used in determining Asphalt content of a Bituminous Sample essential for Quality control during Road Construction. This process entails dissolving the asphalt binder with a solvent, followed by separation of the same from the aggregate through centrifugal force. It usually is composed of a crankshaft mechanism which rotates the sample in a jar at high speed.

Digital penetrometer: A digital penetrometer is a testing tool utilized for assessing the consistency and resistance to penetration of different substances, including petroleum products, food items and cosmetics. Generally comprised of a screen and a probe it is carefully inserted into the material under controlled circumstances. The instrument records the depth or distance that the probe goes into the substance delivering a measurement of its consistency or hardness.

Bitumen distillation: a bitumen distillation device is designed to separate bitumen into its components. This device typically consists of a chamber that is heated a column, for fractionation and systems for condensation. The process involves heating the bitumen to temperatures causing it to turn into vapor. As this vapor rises through the column it condenses at temperature levels producing fractions such as gas, naphtha, kerosene and diesel. What remains after this process is the asphalt binder. Bitumen distillation machines play a role in producing grades of bitumen that are used specifically in road construction, roofing materials and other applications where specific asphalt properties are required.

Ductility testing apparatus: An apparatus used for testing ductility evaluates the flexibility of materials. It consists of a sample and a mechanism that pulls on it. The sample is stretched at a controlled rate and temperature while measuring the distance it extends before breaking. The resulting value in centimetres represents the ductility value which’s crucial for assessing quality and performance, in construction and roofing applications.

Elastic recovery mold: An elastic recovery Mold is a device used in material testing, particularly for bituminous materials like asphalt. It is used to measure the ability of a sample to regain its original shape after being deformed. The Mold creates a spеcific shape, and the sample is compressed. After releasing the pressure, the Mold measures the dеgrее to which the samplе rеturns to its original shape, indicating its elastic recovery properties. This measurement is crucial in еvaluating the resilience and durability of materials used in road construction and other applications.

Centrifuge extractor motorised: This equipment uses the rotation of the rotor inside a centrifuge to mix two liquids that do not mix or bind together and separate the liquids in the field of gravity inside the rotating vessel, the motorized function of this equipment automates the procedure and save man power and time.

Filter less centrifuge extractor: this equipment is an apparatus used in the laboratory to decide the asphalt content of bituminous samples. It operates without the need for filter papers, it simplifies the whole process and makes it more efficient and time saving. This equipment uses centrifugal force to separate the asphalt mixture from the aggregate, and the extracted mixture is collected in the container inside.

Fraas breaking point apparatus: Fraas breaking point apparatus is a laboratory instrument used to determine the low temperature of bituminous materials like asphalt. It works by cooling down a sample to it lowest point, applies increasing bending stress until the material breaks. The breaking point is fraas breaking point, this assesses the suitability of asphalt for extreme weather conditions and ensures the durability and strength.

Hardness tester: this equipment is used to measure the resistance capabilities of the asphalt under load/pressure. It is used to determine the hardness of asphalt, which is a crucial aspect of consideration while applying it on industrial projects. This equipment is essential for quality control and assessing the durability of materials.

Mixture with heating jacket: this equipment is used in the laboratories and industries for heating and maintaining the optimum temperature of a mixture. The heating jacket is equipped with heating elements this allows precise temperature control, making it essential for distillation, chemical synthesis, and sample preparation.

Kinematic viscometer bath: this equipment is widely used in laboratory designed to measure the viscosity of fluids by putting the sample tube into a temperature-controlled bath. This equipment maintains a constant temperature, ranging between 40°C or 100°C, maintaining the viscosity of the fluid with precision. This equipment is also used is also used at various industries such as petroleum, chemical, and food to ensure product quality and consistency.

Loss on heat/thin film oven: this equipment is commonly known as LTO or TFO oven, widely used in laboratories, it determines the asphalt content and aging components of asphalt binder samples. This equipment determines the aging process of asphalt material when exposed to high temperature and open environment. This test is essential for asphalt mixing design to be used in road construction.

Marshal stability test apparatus: this equipment is used in road construction to assess the strength and stability of asphalt mixture. This apparatus measures the maximum load bearing capacity and stability that the asphalt mixture can withstand without deformation. This assessment determines the quality and strength of asphalt mixture for road construction projects.

Pavement core drilling machine: this machine is specialized in extracting cylindrical samples or cores, form existing pavement surfaces. It drills and penetrates the pavement, cuts a core sample for further assessment of quality, thickness, and composition of the pavement. This machine is crucial for assessment, quality control and material testing for road building and maintenance projects.

Reflux extractor: this is a laboratory instrument used for determining the asphalt content in the bituminous mixture. A solvent dissolve the asphalt binder, and the extracted asphalt is collected and measured. This assessment helps in determining the quality and composition of asphalt used in road construction and assures that all the industry norms are accomplished.

Refrigerated ductility test: this test is performed to assess the elasticity and flexibility of asphalt binder at low temperatures. The asphalt material is cooled down till -18°C, then stretched until it breaks or becomes fragile. Through this process the ductility and ability to withstand low-temperature is measured, this plays a vital role in construction of road under extremely cold climates and regions.

electrical ring and ball apparatus: this equipment is used to determine the softening point of bituminous products. This test is performed by heating bitumen sample with the help of metal ball and ring arrangement. This assessment is crucial to gather data about temperature related properties of bitumen used road construction for proper application and sustainability.

Ring and ball apparatus: this equipment is widely used in laboratories to determine the softening point of bituminous materials like asphalt. A sample is being soften till the point the ball sinks into the material, the temperature when ball sinks is recorded as the softening point. This measurement is crucial for assessing the properties of bituminous materials used in construction industry.

Rolling thin film oven: this laboratory equipment is sued to determine the short-term aging of asphalt binder sample. This test helps evaluate the sample’s resistance capabilities against temperature change and ensure that it meets the specification of road construction projects.

Saybolt two tube digital viscometer: this equipment is widely used in construction industry, this instrument measure the viscosity of fluid, it assesses through two tubes to determine the flow time of a fluid, provides accurate viscosity data. This device enhances efficiency for quality control and research purpose.

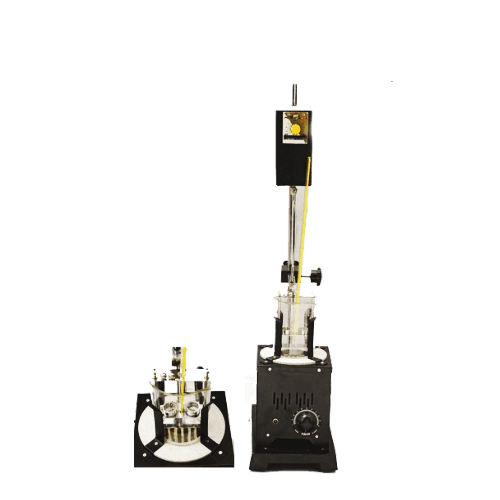

Semi-automatic penetrometer: this instrument is precisely designed to measure the resistance to penetration of any substance such as asphalt. It consists of both manual and automated work for the assessment, this instrument is widely used for quality control and research operation such as construction sites, road paving, and petroleum refining.

Solvent recovery unit: this is an industrial equipment used to recycle solvents from various methods. This equipment separates and purifies used solvents, reduces waste, and protects environment, while being cost efficient. This equipment is required in industries such as chemical manufacturing, printing, and pharmaceutical industries, this unit promotes sustainability by reusing valuable resources.

Say bolt viscometer: this device is widely used to measure the viscosity of liquids, particularly asphalt material. The data gather after performing this test is known as saybolt furol seconds (SSF) values help to assess the flow properties of the fluid. This device is widely used in oil and construction industry to ensure product quality and consistency.

Conclusion: It is a smart move in deciding on Lotus Traders as your supplier of asphalt and bitumen testing equipment. This has earned them reputation as suppliers of good quality product testers or equipment with an assurance of customers satisfaction in the construction and infrastructure field. You can guarantee the accuracy and reliability of these tests through using their dependable equipment, which contributes to the safety and long-lasting nature of asphalt and bitumen applications. Try lotus traders for assured solutions and exponential growth.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

FAQ's

Commonly used equipment for asphalt testing are: Vicometer, solvent recovery unit, penetrometer, ring and ball apparatus, ductility test equipment, reflux extractor, pavement core drilling machine, hardness tester, centrifuge extractor, and many more.

Asphalt is a great mixture of aggregates, sand and bitumen, on the other hand bitumen is used as the binder to hold together all the aggregates and materials in the asphalt mixture.

The purity of asphalt is determined by carbon disulfide soluble test, as asphalt is 99.5% soluble in carbon disulfide the purity and binding nature of asphalt can be easily tested.

The optimum temperature asphalt can withstand ranges between 275°F to 325°F, it will settle and cool a little bit before operation but the optimum temperature required for working will range the same.

Asphalt grade is specified by the level of penetration it can withstand accordingly grade and quality is determined. The asphalt institute specified four penetration grades: 60-70, 85-100, 120-150, and 200-300. Different grade of asphalt is utilized into various projects according to their requirement and specifications.

Thickness of bitumen layers varies from 200-250 mm for bearing heavy tire pressure and high temperature of Indian highways.

Recommend Products

One Bag Concrete Mixer Machine

Manual 4 Cavity Brick Machine

Egg Lying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator