premium supplier for Automatic Grinding Machine in India.

lotus traders is the most trusted and premium supplier for automatic grinding machine all over India.

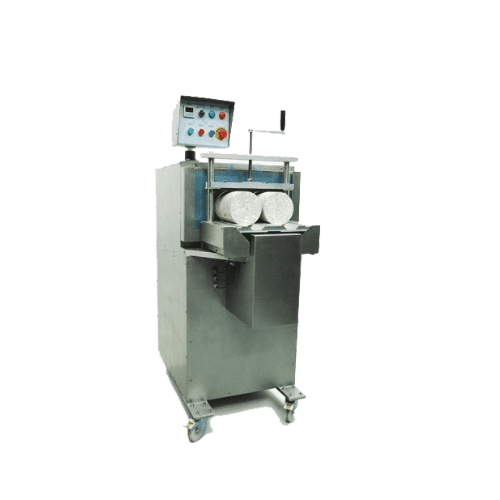

Automatic Grinding Machine

- High Quality Materials

- Compliance With Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Dimensions | 730*1080*1510 mm |

Weight (approx.) | 280kg |

Power | 1850w |

What is Automatic grinding machine?

An automatic grinding machine can be described as an extremely complex device developed to facilitate the metalworking process. It works using advanced technologies with very minimal human interference to improve the efficiency and accuracy. This type of specialized equipment uses abrasive wheels to cut the material workpieces, resulting in the desired shapes and surface finishes. Equipped with very sophisticated sensors and also controls, the automated grinder modulates grinding parameters accurately thereby ensuring uniform results while minimizing any errors. Its flexibility enables the handling of many diverse materials ranging from metals to ceramics.

This machine is automatized, which makes it possible to reduce the labour costs and thereby raise the productivity in industrial environments. It has many adjustable modes and flexible character offering a lot of multi-purpose use that is at the heart of modern machining practices. To conclude, the automatic grinding machine aids as an example of technological advancement in the search for exactitude, speed and dependability with metalworking operations.

Table of Contents

What Are the Key Features of Automatic grinding machine?

Automation: Automated machines greatly reduce the need for the human involvement in their operation and thus increase efficacy.

Precision Control: The automatic grinding machines are constructed with modern control systems which enable precise material removal, thereby enabling close tolerances.

Versatility: These machines accommodate different materials and also geometries with various grinding applications.

Consistent Quality: Hence, automation provides a same uniform grinding process and as a result yields high quality finished product.

Efficiency: Automated workflows enable these machines to make the most of the production cycles by reducing downtime and also enhancing yields.

Safety Measures: Workplace safety is enhanced due to the integrated safety features which minimize the supplying risks associated with manual grinding processes.

Adaptability: With the adjustable parameters, the users are provided with an opportunity to adapt grinding settings as per their certain needs and also varying production requirements.

Monitoring and Feedback: Certain models include monitoring systems to monitor the performance and enable real-time optimization.

Tooling Options: These machines are able to adapt itself for the diverse applications and also material types by supporting a wide variety of grinding tools.

User-Friendly Interface: The intuitive user interfaces allow the operators to be able to freely program and also monitor the grinding process

How Does the Automatic grinding machine works?

An automatic grinding machine functions through the application of computerized controls to control rotation, speed and pressure applied on a grinding wheel in the material removal. Grinding usually starts by placing the workpiece onto a fixture or a conveyor belt, which positions it for grinding. The sensors and programming on the machine provide very accurate measurements and also movements. When it started, the grinding wheel is usually provided with abrasive particles and come into action on the workpiece’s surface.

The grinding parameters, including the depth of cut and the feed rate detail, are coordinated by the machine’s algorithms to meet standards is how efficient can it be made. By continuous monitoring and making adjustments, such results are predictably consistent. More sophisticated systems may have a built-in feedback mechanism to compensate for the different material hardness or forced changes depending on the circumstances.

In terms of efficiency, the automatic grinding machine simplifies repetitive activities and improves productivity and accuracy over the manual operation. Newer versions might be able to be combined with the automatic tool changing, coolant systems and also quality inspection to create more efficiency.

What are the Application of Automatic grinding machine?

For grinding metal, ceramics or any other materials in manufacturing to obtain the desired shapes and surface characteristics, these machines automate the process. They are very invaluable for improving the product quality, eliminating manual human effort and also promoting uniformity. In the automotive industry, automatic grinding machines perform the finishing of components such as engine parts or gears to make their dimensions accurate and surfaces smooth. In the aerospace industry, they are very essential in forming and working on components that have tight tolerances. They are also used in the manufacture of medical devices which require a lot of precision.

Though automatic grinding machines are very costly, they possess the efficiency and repeatability that make them a very vital in industries where high level of accuracy and productivity is required. Through the automation of the grinding process, these machines enhance the throughput rates and result in lower cost as well as better quality overall products.

What are the Advantages of Automatic grinding machine ?

A number of benefits come with the automatic grinding machines. To begin with, by eliminating the bulk of manual labour, these tools increase productivity. Such machines work round the clock, producing a constant output without any stops. Second, they also help to achieve greater accuracy and precision in the grinding tasks leading to better-quality finished goods. Automation reduces the likelihood of any human error, making the results more uniform and also replicable.

Secondly, automatic grinding machines increase the safety by minimizing the presence of human intervention in dangerous procedures. They are usually built with many safety measures and sensors to avoid any mishaps. Additionally, these machines are very effective for even the most complicated jobs enabling diversified uses in various fields. All in all, these advantages include a higher output level, better accuracy and safety as well as the ability to grind different grinding tasks successfully

Why Buy From Lotus Traders?

the automatic grinding machine is a major breakthrough in precision and efficiency levels for the industrial processes.

Its automatized functions optimize the process, minimizing all human labour and also contributing to the general efficiency. The ability of the machine to produces precise outcomes contributes significantly towards the better product quality.

Second, it improves the workplace safety by reducing human involvement. Advanced technologies such as sensors and adaptive control systems make it possible for the machine to adjust different workpieces, more improving the productivity.

Although the automatic grinding machine may require an initial investment, these costs are far outweighed by the potential benefits of increased output and lower errors in processing the material. In general, this technology is likely to disrupt the grinding processes by providing a sustainable and economical solution for the contemporary manufacturing problems.

Frequently Asked Questions

Automatic grinding machine is a very useful tool that operates as an automatic material removal system, using abrasive tools to grind the workpiece.

These machines employ the CNC systems that allow for a accurate control of grinding movements thereby ensuring precision and also efficiency.

The automatic grinding machines are very diverse and handle a broad range of materials like metals, ceramics, and also plastics.

Major advantages are the better accuracy, lower labor costs and also greater efficiency through the automation process.

Indeed, numerous automatic grinding machines are built to accommodate the complex shapes and contours; thus, they can be used in various fields without any limitations.

With regular maintenance, for instance tool inspection and replacement ensuring the best performance and also life.

Indeed, many modern machines have a lot of safety mechanisms like emergency stops and protective enclosures installed to guarantee the operator’s wellbeing.

Basic training is always needed, but the user-friendly interfaces of many machines allow the operators with limited experience to run the equipment.