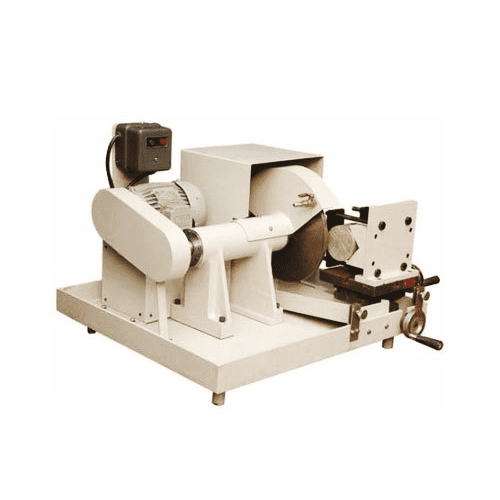

Core Cutting Grinding Machine

- High Quality Materials

- Compliance With Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Usage | Metal Sheet, Paper, Plastic Sheet |

Material for Construction | Stainless Steel |

What is core cutting grinding machine ?

Cylindrical core processing tool for a precise operation in various materials. It boasts an impressive architecture and also modern technology that will deliver the precise results every time. Fitted with a formidable grinder, this tool is highly effective in the sculpting. Refined core samples for various uses including geological studies, building projects and also testing of materials. With a simple interface and customizable settings for the core dimensions, it is very easy to operate.

When used in the laboratories or even outside, this device becomes inevitable for professionals who require reliability and precision of the core cutting and grinding. It is a very vital resource for the industries that depend on the accurate core analysis and also sample preparation because of its efficiency and versatility.

Table of Contents

What Are the Key Features of core cutting grinding machine ?

Powerful Motor: With a powerful motor that delivers enough power to the facilitate high-quality core cutting and also grinding.

Adjustable Cutting Depth: It enables the users to adjust the cutting depth, providing accuracy and flexibility depending on material type.

Durable Blades: Has high-quality, long-lasting blades that are made to face the sturdy materials with ease and regularity.

Safety Features: Adopts safeguards in the form of protective guards and also emergency stop features to improve user safety during the operation.

Versatility: The cutting edge is designed for various core technological operations, making it fit both in different applications and also materials.

Sturdy Construction: With a very strong and sturdy structure that can withstand rigorous use for the long-term success.

Portability: Sleek and mobile form factor for the easier transportation between the jobsites.

Dust Collection System: Fitted with a modern dust extraction system which allows to keep an unpolluted work space and also ensures the safety of operator’s body parts from the contaminated air.

User-Friendly Controls: Intuitive controls, which enable not only the specialist but also an ordinary person to obtain the ideal results.

Optional Accessories: Compatible with many accessories to increase the functionality like not unique blade types for specific cutting needs.

How Does the corer cutting grinding machine Work?

A Core Cutting and Grinding Machine is used to cut and grind the core samples in different materials with accuracy. The process necessitates compression fixturing, where the sample is secured in a fixture by clamps for stability while being cut and ground. The cutting tool in the machine uses a diamond or an abrasive wheel that rotates to slice through the core, creating an accurate cross-sectional slab. Cutting requires the manipulation of the feed rate and cutting depth as per the chosen thickness.

The following grind stage smoothens the surface of the sample for microscopic analysis, or any other testing purpose that involves rough cutting. There may be coolant systems within the machine to prevent the overheating.

Besides, the automated controls are also available on some of the machines for a better accuracy. Regular maintenance of the cutting wheel and appropriate safety measures are very vital to ensure the proper functioning as well as a safe operation in the Core Cutting Grinding Machine.

What are the Application of core cutting grinding machine ?

A Core Cutting Grinding Machine is a multipurpose tool mainly applied for the construction and civil engineering. Its main function is to provide accurate cutting and grinding of the cylindrical cores made from different construction materials such as concrete or asphalt. This machine is very important in quality control and research because it helps the engineers to take samples for testing the compressive strength, density of material and other parameters.

The Core Cutting Grinding Machine is used in the construction projects to cut cores from structures that are already present for the structural evaluation or verification of integrity on concrete components. The extracted cores are used in the laboratory as samples of materials, which help to determine the material quality and structural integrity. Also, this is an also important machine when making the openings need in pitching walls or floors for utility installations during quality assurance and construction processes.

What are the Advantages of core cutting grinding machine ?

A Core Cutting Grinding Machine has the ability to prepare cylindrical samples from hard materials like concrete and rock with a high precision and efficiency. Its big strength is the provision of consistent and quality cores for the testing purposes which guarantee reliable results in construction and material analysis. The other features that increase the efficiency are the ability to produce cores quickly and with a minimal wastage of time as well as resources. Also, it makes the core extraction from existing structures easier and less destructive.

Precision in cutting and grinding is also considered to contribute greatly to the quality of the samples obtained, which is important for evaluation material properties. In conclusion, the Core Cutting Grinding Machine improves the core preparation process by offering reliability, efficiency and accuracy in a wide variety of applications from construction projects to scientific researches.

Why Buy From Lotus Traders?

The Core Cutting Grinding Machine is a very important tool in several industries that could easily cut and grind core samples quickly and also accurately. It’s very sturdy construction promotes the longevity, and the advanced functionality greatly improves operational performance. The flexibility of the machine allows for many modifications, adapting to different types and also sizes of materials.

The simple user interface allows the operators to navigate and refine the cutting and grinding processes. Such integrated safety measures are very focused on the user’s well-being. In total, this machine greatly simplifies the core processing and enables the production of dependable results in cases related to geological applications or for construction purposes. As a result of its exceptional performance coupled with durability and user-oriented design, the Core Cutting Grinding Machine proves to be an invaluable item for use on material analyses testing.

Frequently Asked Questions

The Core Cutting Grinding Machine is a specialized apparatus designed for the accurate cutting and grinding of cylindrical cores, specifically in materials such as concrete

The machine uses a diamond-cutting wheel that allows for the precise core cutting and is followed by grinding to finish the surface.

Widely used in the construction and also civil engineering for drilling core samples, evaluating the quality of materials involved, as well as conducting numerous tests.

Core Cutting and Grinding Machines generally cater to a variety of core diameters, frequently adjustable for flexibility.

Some machines with designs depending on the model are very portable, allowing for field testing and analysis.

Typical maintenance tasks include regular cleaning, lubrication of the moving parts and also replacement of the diamond wheel periodically.

Machines have many safety mechanisms like emergency stops and also protective guards to ensure the user’s security when in use.

Often are electrically driven, calling for a standard power source to function