Home > Rock Testing Equipment > Rock Bolt Pull Out

Rock Bolt Pull Out

Ratings :

☆☆☆☆☆ Rated 4.5 out of 5

- High Quality Materials

- Compliance With Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

Rock Bolt Pull Out:

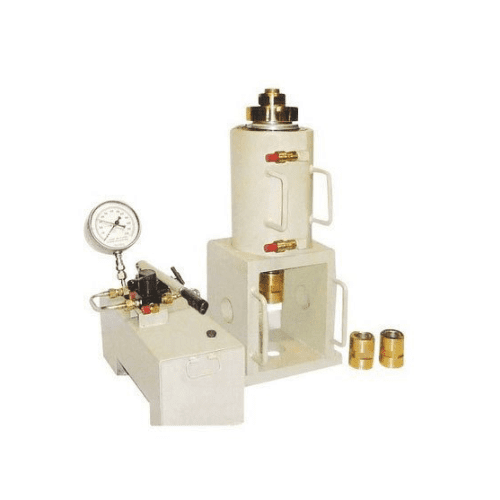

A rock bolt pull out machine is a specialized piece of equipment used to test the performance of rock bolts, which are commonly used in mining, tunneling, and civil engineering projects to stabilize rock formations. The primary purpose of this machine is to evaluate the holding capacity and performance of rock bolts by applying a controlled pulling force until the bolt either slips or is pulled out from the rock.

Key Components and Features of a Rock Bolt Pull-Out Machine:

Hydraulic System:

- The machine typically uses a hydraulic system to generate the pulling force. The hydraulic system can apply a controlled and measurable load to the rock bolt, allowing for precise testing.

Load Cell:

- A load cell is integrated into the system to measure the force applied to the rock bolt during the test. This data is crucial for determining the pull-out strength of the bolt.

Displacement Sensor:

- Displacement sensors measure the movement of the bolt as it is pulled out. This helps in assessing the deformation and behavior of the bolt under load.

Control Unit:

- The control unit manages the hydraulic system and records the data from the load cell and displacement sensors. It may also allow the operator to set parameters like the rate of loading.

Anchorage System:

- The machine must securely anchor the surrounding rock or concrete to ensure that the force applied to the bolt is properly directed and measured.

Portable or Stationary Models:

- Some machines are portable, designed for field testing, while others are stationary, used in laboratory settings for more controlled testing.

Applications:

- Mining and Tunneling: Rock bolts are used to stabilize underground excavations, and testing their strength is critical for ensuring safety.

- Civil Engineering: In projects like dam construction, slope stabilization, or foundation work, rock bolts are used to secure rock faces or large structures.

- Quality Control: Manufacturers of rock bolts use pull-out machines to test the quality and performance of their products.

Testing Process:

- Installation: The rock bolt is installed into the rock or a test block. The pull-out machine is then set up around the bolt.

- Loading: The machine applies a gradual load to the bolt using the hydraulic system.

- Data Collection: The load applied and the displacement of the bolt are recorded until failure occurs (either slippage or complete pull-out).

- Analysis: The data is analyzed to determine the pull-out strength and performance characteristics of the rock bolt.

Advantages:

- Safety: Testing ensures that rock bolts meet the necessary safety standards for their intended use.

- Quality Assurance: Manufacturers can ensure their products perform as expected.

- Field Testing: Portable machines allow for on-site testing, which can be crucial for projects in remote locations.

Similar Product