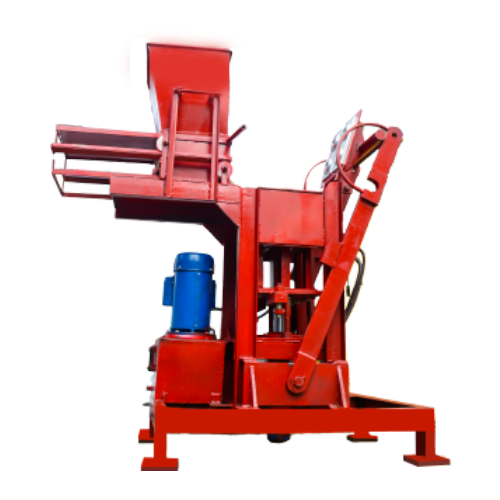

Earth Compactor Machine

The earth compactor comes in three variants – the smallest can handle up to 2/3 ton capacity, while the largest can hold 5 tons!

Earth Compactor Machine

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- LT3ED Specification

| FEATURES | SPECIFICATION |

| Capacity | 3 Ton |

| Engine Model | 1520 Greaves engine |

| Engine Make | Greaves engine |

| Base Plate | 10 mm |

| Plate Size | 450X600 mm |

| Weight | 130 |

| Hp | 5 Hp |

What is an Earth Compactor?

The earth compactor goes by many names – it additionally identifies as a soil compactor or a compaction machine.

This top-level construction equipment compresses and compacts various qualities of soil, gravel, or other granular materials to increase their density and enhance their load-bearing capacity. Compaction is integral to civil engineering projects because supervisors strive to reduce the risk of providing stable foundations for buildings, roads, bridges, and other structures.

The soil Compactor machine is not limited to one variant; it comes in various sizes and configurations! There are walk-behind compactors, ride-on compactors, and heavy-duty machines for complex projects – it all depends on what you are looking for.

This article will explore the basics of the compactor machine, its features, usage-case scenarios, and the unique relevance it brings to the construction industry. Buckle up for the finer details!

Table of Contents

What Are the Key Features of the Earth Compactor ?

Every earth compactor has identical features and characteristics that align across each model. All promise the same efficiency – to compact soil and other granular materials in construction projects.

Here are the most prominent features you will find in an earth compactor:

The conventional compaction mechanism: The soil compactor needs a heavy roller or a vibrating plate to carry out the compaction mechanism. Rollers are ideal for large projects, but vibrating plates suit smaller areas and focus on precise compacting.

The powerful engine: The heart makes the man, and the engine completes the machine! The soil compactor machine needs a power source robust enough to meet its needs, and the power output can vary depending on the size and type of the compactor.

The weight and size of the machine: The soil compactor machine’s weight determines its compacting capabilities. A large compactor machine can deliver more force to the soil to form higher compaction densities. The smaller compactor is portable through tight spaces, making it the more maneuverable alternative.

The vibration frequency and amplitude: The vibrator plate model boasts adjustable vibration frequencies and amplitudes, allowing site operators to manually increase or decrease the compacting impact on the target soil.

The electric control system: While traditional soil compactors exhibit user-friendly controls like starting and stopping the machine, modern models have come to the market with sophisticated control systems that guarantee precise operation.

The water spray system: Some technically advanced models have dedicated water systems to moisten the soil during the procedure. Now, you may think the primary purpose of an compactor machine is to reduce moisture, but this improves efficiency in certain conditions!

The traction and stability equipment: Accidents are a feeble thing that may happen in the blink of an eye, so manufacturers make it a compulsion to build the finest earth compactor models with smooth, Padfoot drum surfaces for rollers and rubber or steel plates for vibrating plate compactors, to provide versatility across several types of terrain.

These key features accentuate the suitability of a soil compactor machine for a particular construction project!

How Does the Earth Compactor Work?

The earth compactor’s specific operation may vary depending on the make and model, but the fundamental principles do not change. Its primary role is to increase the soil density, which it does by adhering to the following steps:

First, site engineers must level and spread the soil evenly over the desired surface before applying the compactor. Large rocks or foreign objects can challenge the compacting process!

Second, the compactor begins to work, and operators adjust any necessary settings beforehand, such as vibration frequency or amplitude for vibrating plate compactors.

Third, operators guide the machine over the desired area to ensure even coverage. In the roller model variants, the machine’s weight helps in the compaction force, as the smooth or padfoot drum flattens the soil. In vibrating plate compactors, the plate moves up and down forcefully, exerting even pressure below.

Fourth, there’s a critical overlapping step. This overlap is to achieve uniform compaction. The degree of overlap depends on the compactor’s width and the compaction requirements for the project.

Fifth, watering is an optional step! Clay soil needs a water spray system to moisten the texture during the compacting. By doing so, the machine improves the soil’s efficiency and resistance to crumbling.

Sixth, operators must keep a close eye on the compacting process. Modern compactor machine come with in-built analysis systems to track compaction depth, density, or the number of passes made. Perfection always depends on humane supervision!

Remember – after the passes end, additional touches may be necessary to fine-tune the soil compression in specific areas to achieve the desired result.

Finally, after the compacting process is over, turn off the soil compactor!

The compaction process works by rearranging soil particles and eliminating air voids within the soil or material. This increased density enhances the load-bearing capacity of the compacted surface, reduces settlement, and creates a stable foundation for construction projects like roads, buildings, or other structures.

Where is the Earth Compactor Applicable?

You cannot underestimate the importance of the earth compactor in the construction industry! It is paramount across several engineering projects and has established a solid track record of delivering top-quality results.

Expect the soil compactor to be a crucial asset for:

Road and highway construction: The soil compactor machine compacts the soil used in the roadbed and sub base layers to ensure the road is durable and can withstand the brunt of heavy vehicles for a long time.

Building robust foundations: A building should always be on top of stable soil to prevent unwanted accidents. The soil compactor machine makes this possible by preventing settling and uneven settling of the architecture.

Parking lots: All parking lots require well-compacted surfaces to support vehicle weight. They also need pathways for a stable flow of incoming and outgoing traffic.

Airport runway strips: A plane can never take off from an uneven surface! If aircraft safety during takeoff and landing matters, the even compaction of these runway strips is paramount.

Railroads and dams: Railroad tracks need a stable base to prevent track settlement. Gigantic dams need properly compacted embankment bases to ensure their stability.

Trench back filling: When situations demand trenches for water, sewer, or gas lines, using the earth compactor to compact the backfill material is necessary to maintain the integrity of the utility lines.

Sports arenas: Competitive fields like those used for football or baseball benefit from proper compact to remove any uneven spots or hazardous playing surfaces.

This list is not exhaustive; the soil compactor machine is integral to more scenarios like making foundations for retaining walls, pipeline trenches, compaction of fill materials, etc. The applicability varies, but the efficiency stays the same.

What Are the Advantages of the Earth Compactor?

Since the earth compactor is a widely applicable piece of equipment, you can find a host of advantages lining up to authenticate its ingenuity!

Here’s a short list of its most conspicuous advantages:

It improves load-bearing capacity. Since compaction increases soil density, it also magnifies the load-bearing capability. Structures like buildings, roads, and bridges need stable foundations to support them.

It prevents settlement. The earth compactor minimizes settling that can occur over time. This phenomenon is natural, as soil compresses under weight, but proper compaction can eliminate this.

It improves drainage. Once the soil undergoes proper compaction, there are fewer voids and channels to prevent drainage leaks. Hence, it becomes easier to reduce corrosion or water-related damage.

It smoothens surfaces. This advantage takes the cake home! Anything the modern construction industry thinks about the building has to remember to integrate aesthetics into the discussion. Since compaction results in smoother and even surfaces, the compactor machine is integral to building roadways, parking lots, and other plain areas.

Other undisputable benefits like reduction in excavation and disposal, the versatility of the soil compactor across earth moving projects, and its commitment to provide uniform density throughout the project area make it a popular choice!

Today, the earth compactor has adopted a crucial role in the construction industry as an indispensable tool for ensuring structural integrity and longevity in all projects. If you are looking for an ideal earth compactor, visit our shop today to look at our best models!

Besides dealing in soil compactors, we also keep stock of other construction-related equipment, from one-bag cement mixer machines to vibrators and premium trimix systems! Why wait? Book a session with us to comprehend what you want for your upcoming project!

Watch Video of Earth Compactor

Frequently Asked Questions

The earth compactor compresses and compacts various qualities of soil, gravel, or other granular materials to increase their density and enhance their load-bearing capacity.

The earth compactor improves load-bearing capacity, prevents settlement, improves drainage, and smoothes surfaces.

An earth compactor is not a technically complicated device. However, follow proper manufacturing guidelines before using one.

Yes, Lotus Traders has the best models related to the earth compactor, so feel free to drop us a visit!

All safety-related guidelines are prescribed in the manual, and site experts will guide the user before putting the earth compactor to good use.