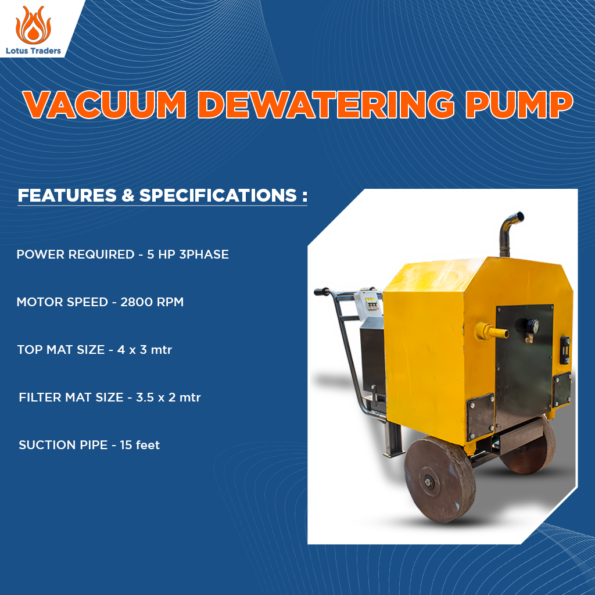

The New Vacuum Dewatering Pump Machine

The vacuum dewatering pump boasts a 15-meter suction pipe that is incomparably reliable for reaching inaccessible areas to remove unwanted water from newly built concrete surfaces!

Vacuum Dewatering Pump

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

FEATURES | SPECIFICATION |

Power Required | 5 HP 3Phase |

Motor Speed | 2800 RPM |

Top Mat Size | 4×3 mtr |

Filter Mat Size | 3.5×2 mtr |

Suction Pipe | 15 feet |

What is a Vacuum Dewatering Pump?

A vacuum dewatering pump is an incredible device used in the construction industry! Its primary purpose is to remove excess water from freshly curated concrete slabs or floors. This process makes it convenient to improve the concrete’s durability and reduce its porosity, giving shape to strengthened outputs.

As water can dampen a concrete surface, it is imperative to remove the excess before giving the green light to move ahead in a project. Therefore, the vacuum dewatering pump is a piece of supreme equipment for its efficiency because modern construction projects cannot proceed without depending on it.

This article will explain the distinct features of a vacuum dewatering pump, how it works, its relevance to the construction industry, and its unique factor in lending unparalleled assistance to construction projects. Keep reading for the juiciest details!

Table of Contents

What Are the Key Features of the Vacuum Dewatering Pump?

The vacuum dewatering pump‘s features are manifold, and we seek to explain all in serial down below. Effective dewatering is a task it excels at, and it would not be possible to do so without:

The vacuum pump assembly: This piece is the heart of the dewatering pump! It gives origin to the vacuum pressure needed for drawing the unnecessary water out of the concrete.

The dewatering mat: There’s no removing water without a dewatering pad, conveniently placed on top of the concrete to suck out the water without attracting the cement particles. This pad has porous material.

The sealing mechanism: Manufacturers always produce a sealing feature to assist the dewatering mat and keep it attached to the concrete surface. The sealed chamber helps to maintain the vacuum pressure!

Hoses and additional connections: These pipes connect the pump and the dewatering mat to ensure a secure and airtight connection.

The vacuum gauge: The vacuum or pressure gauge assists operators in monitoring or controlling the vacuum pressure. Too much or too little pressure can dampen the concrete’s long-term quality!

The dedicated water collection system: There is little doubt the dewatering pump needs a tank to contain the extracted water! This feature is crucial; the device cannot exist without it.

The control panel: The sophisticated models present high-tech control panels to adjust pressure volume, monitor the process, and prevent unwanted mishaps.

The wheels and handles: The machine needs to promise portability, and it does so by offering conventional wheels and handles to move around a single construction site.

The power source: The power source depends on the make and model – the dewatering pump runs on electricity, diesel engines, or other suitable power alternatives

How Does the Vacuum Dewatering Pump Work?

The vacuum dewatering pump performs sublime work, but it is not complex. It’s an operate-and-go procedure, but let us break this down in simpler terms.

First, the general step of pouring and leveling fresh concrete onto the site occurs. This concrete usually contains excess water and air voids.

Second, operators place the dewatering mat over the freshly poured concrete. This mat has synthetic materials and allows a streamlined passage of water without disturbing the cement particles.

Before turning on the dewatering pump, the mat’s edges are sealed to the concrete surface, creating an airtight chamber.

Fourth, operators turn on the vacuum pump, which removes air from the chamber above the concrete. As the air pressure decreases, the pressure differential between the concrete surface and the sealed chamber magnifies.

Fifth, the water extraction process comes to life! All the unwanted particles get sucked upward, culminating through the pores and capillaries to land in the chamber.

An additional step operators follow in monitoring the vacuum pressure is with a vacuum or pressure gauge. You cannot mess up the pressure requirements!

After the water extraction, the concrete hardens to a certain degree. It is now more solid, with reduced porosity and improved strength and durability.

These are the most significant steps to make good use of the vacuum dewatering pump

What Are the Advantages of the Vacuum Dewatering Pump?

The vacuum dewatering pump offers many advantages over its competitors, considering it is a unique asset in enhancing the quality and durability of concrete surfaces.

Here is a list detailing the most crucial benefits this machine enforces over a construction project:

Uncompromised concrete strength: The consistent quality in the dewatering process gives rise to denser and more durable concrete. This factor elevates the compressive strength and makes the concrete resistant to overtime cracking.

The reduction in porosity: After removing the excess water and air voids, the concrete becomes less penetrative. Lower permeability means the concrete is less susceptible to water penetration, freeze-thaw damage, and chemical attacks.

Enhanced surface finish: The dewatering pump assists in producing an aesthetic finish, too! It delivers a smoother and flatter concrete surface, paramount for industrial floors, airport runway strips, or highway pavements.

Faster curing timeline: The concrete curing process accelerates after using the dewatering pump, meaning it reaches its desired strength in a shorter timeline, allowing for rapid construction processes.

Reduction in surface cracks: Vacuum dewatering miraculously reduces the risk of surface cracking and defects. Just kidding; it is not a miracle, but because of the water reduction!

Underrated environmental benefits: There is an overall reduction of wastewater generation during the construction timeline. The dewatering pump also reduces the persistent need for chemical additives to enhance concrete properties.

Where Is the Vacuum Dewatering Pump Applicable?

The vacuum dewatering pump is an indispensable tool for construction projects that follow strict guidelines and abhor compromising the quality and durability of the concrete. It is applicable across several scenarios, such as:

Industrial flooring: Industrial facilities, warehouses, and manufacturing plants use the dewatering pump to create high-quality concrete floors. Along with the aesthetics, they must be durable enough to withstand heavy loads, abrasion, and chemical exposure!

Highways and Road Construction: Smooth road surfaces highlight the economic prosperity of a country, so the dewatering pump lends incredible assistance to achieve this task and ensure the longevity of transportation infrastructure.

Airport runways: It is essential to create robust, flat runways that can bear the heavy weight and aircraft traffic. Smooth strips also prevent surface damage due to constant landings and takeoffs.

Parking lots: Commercial and industrial areas require high-quality parking spaces that can withstand incoming and outgoing vehicle traffic, which is possible with the help of the dewatering pump.

Buildings and shopping malls: Malls, office buildings, and hotels have a public image to maintain, so they have no choice but to make efficient use of the dewatering pump to produce top-quality flooring.

Warehouses and distribution centers: These spaces undergo constant heavy forklift and pallet jack traffic. Vacuum dewatering ensures the longevity of these surfaces so that they do not wear out quickly.

Data centers: The floors of these scientific spaces need to be exceptionally flat to accommodate sensitive equipment.

Cold storage facilities: Perishable goods like food require freezing spaces to stay fresh. Therefore, scientists use the dewatering pump to create floors that can withstand temperature fluctuations and heavy loads.

These usage-case scenarios are the tip of the iceberg! The vacuum dewatering pump also helps to construct corrosion and chemical-resistant water treatment plants, sports stadiums and arenas, residential complexes, etc. In summary, this machine is most applicable in construction projects demanding high strength, low porosity, smoothness, and durability.

The vacuum dewatering pump stands as a cornerstone of excellence in the construction industry, offering a unique and indispensable role in elevating the quality and longevity of concrete surfaces. If you’re actively looking for one, we keep the best models available in our shop today!

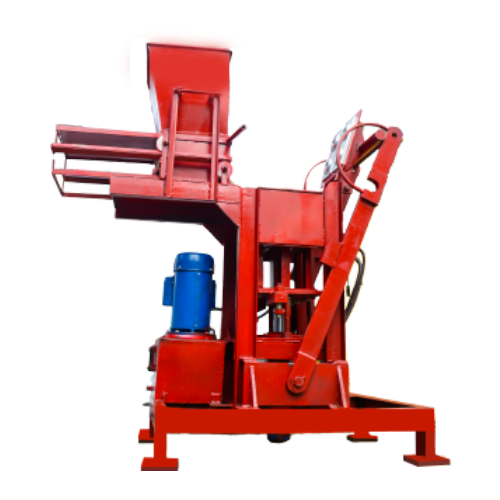

Besides the vacuum dewatering pump, we keep stock of other construction equipment like premium trimix systems, one-bag concrete mixers, vibrator machines, and brick molding machines. If you need to buy a specific product for your next project, contact us today, and we will be happy to guide you through every step of the buying process!

Frequently Asked Questions

A vacuum dewatering pump provides unparalleled concrete strength, reduces porosity, enhances surfaces, and reduces surface cracks!

Yes, Lotus Traders has the best vacuum dewatering pump models. Feel free to drop by!

The vacuum dewatering pump is relatively easy to operate, but adhere to all protocol guidelines before using it.

The conventional models charge around the Rs. 50,000 mark, but expect the sophisticated variants to be over Rs. 2,50,000!