Semi Automatic Concrete Brick & Block Making Machine Manufacturer in India

A semi-automatic concrete block making machine is a versatile and efficient piece of equipment used in the construction industry for your producing various types of concrete blocks and bricks.

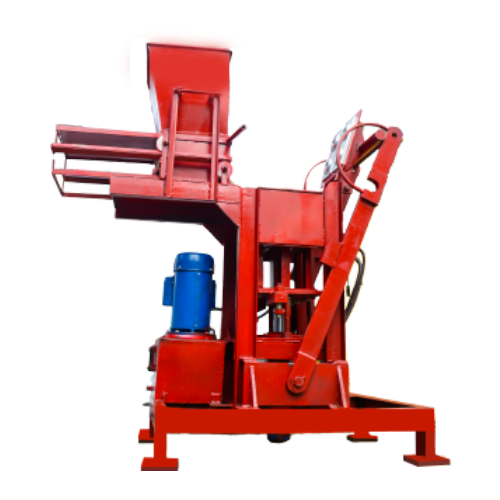

Semi-Automatic Brick & Concrete Block Making Machine (double cavity)

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

Concrete Mixers first came into existence in the 1900s having a simple drum-like structure

powered by steam engine has gone since major modifications till date with continuous

advancement in engineering, keeping up with the evolving needs in the construction sector.

Earlier the Concrete mixers were powered by steam engine, now the concrete mixers usually run

on Diesel but the base drum-shaped body remains the same.

Concrete is majorly used in the construction industry. Concrete is an aggregate of usually

stone or gravel, water and cement. Modern cement is a complex blend of finely ground minerals,

called “Portland”. The cement plays a major role as the binder to the aggregates whereas the

aggregates acts as the filler materials that give strength to concrete. Concrete is made by

combining the three ingredients in a Concrete mixer machine, the water is absorbed by the

cement, which then binds the aggregate together, creating concrete .

FEATURES | SPECIFICATION |

Production Capacity | 3000 Block / Shift, 4000 Brick / Shift |

Power Pack | 7.5 HP (Three Phase) |

Maximum Pressure | 3000 PSI |

Hydraulic Tank | 230 Ltr |

Cavity | 2 for Block / 3 for Brick |

Mould Area | 450 x 450 mm |

Style Of Block can be made | Zigzag, Isec, bricks 9 x 4 x 3 inch |

What is a semi-automatic double cavity concrete brick and block making machine?

A mechanical tool used in the construction industry to make bricks or blocks referred to as a semi-automatic double cavity brick and block making machine. For simultaneously moulding bricks or blocks, it often contains two cavities or moulds. The term “semi-automatic” refers to the fact that some manual labour is needed during the process, especially when loading materials and pulling out the produced bricks or blocks. The effective production of bricks and blocks for the purposes of construction can frequently be achieved with these types of machinery.

The manufacturing of brick and blocks is made simpler by these semi-automatic double cavity brick and block making machines which also increase productivity and effectiveness. Because they combine automation with manual work or labour-intensive jobs, they are ideal for small to medium-sized brick-making industries.

Table of Contents

Key Features of semi-automatic double cavity concrete brick and block making machine:

The semi-automatic double cavity brick and block making machine includes the following significant characteristics:-

- High production rate - Compared to a manual brick making machine a semi-automatic double cavity brick and block making machine has a production rate that is capable of producing 1,200 blocks per hour.

- Minimal labour cost - As there is only one operator needed for the machine therefore labour expenses can be greatly lessen.

- High automation - Because of the machine's high automated processes less human intervention is required. This could increase productivity as well as effectiveness.

- Simple to maintain - It is not difficult to maintain the machine and it does not require a lot of technical expertise or skills and abilities.

- Durability - The machinery is constructed with high-quality components and has been designed to resist the pressures encountered in everyday operation.

Some semi-automatic double cavity brick and block building machines may include the following extra features->

- A conveyor belt for transferring the bricks or blocks to a drying area.

- A water spray system that preserves the moisture level of the bricks or blocks during the formation process.

- A vibration system that assists in compacting the concrete mixture.

- A control centre for monitoring and modifying the machines settings.

Uses of semi-automatic double cavity concrete brick and block making machine

There are numerous instances where a semi-automatic double cavity concrete brick and block making machine can be used for example-

- Construction sites - This machinery is able to manufacture bricks and blocks for applications such as residential, commercial, and transportation-related projects.

- Concrete product manufacturing industries - A wide variety of concrete product including tiles, pavers, and stepping stones can be produced using the machine in plants that produce concrete products.

- Government organizations- These organizations are able to use these machines to make bricks and blocks for construction projects like roads and bridges.

- Small businesses- Small businesses are able to use the machine to create bricks and blocks for personal use and also to sell.

- Educational institutions - The machine can be used by educational institutions to teach students about the construction industry.

Depending on the needs of the customer, a semi-automatic double cavity concrete brick and block production machine may be employed at a particular site. The device however, is a flexible instrument that may be applied in a range of situations.

The following are some of the elements that will impact the machine’s location:

- The size of the machinery -The machine is either transportable or static. When compared to stationary machines which are larger and often installed in a permanent position, portable machines are smaller and easier to move.

- Production capacity - Depending on the machine's production capacity, we may estimate how many bricks or blocks it can make in a certain period of time.

- The machine can make several different types of bricks or blocks - There are numerous sorts of bricks or blocks that can be produced by the machine. The model of the machine will determine the precise kinds of bricks or blocks that it is capable of producing.

- Cost of the machinery - It depends on the type and features of the machine that will have a wide range in pricing.

Benefits of semi-automatic double cavity concrete brick and block making machine

Benefits of semi-automatic double cavity concrete brick and block making machine

- Higher rate of production - Compared to manual processes semi-automatic machines have a significantly higher output rate reaching up to 1,000 blocks per day. For any type of construction project this can help you save time and money.

- Top quality blocks - By removing air bubbles from the concrete using vibration technology the machine produces blocks that are stronger and more lasting. To maintain the structural integrity of your construction the machine also makes sure that the blocks are regular in size and shape.

- Reduced labour expenses- Because the machine only needs a few operators you can reduce labour expenses. This is particularly useful if you are working on a relatively small project.

- Machine versatility - The machine is capable of producing a broad variety of different types of blocks including hollow blocks, solid blocks, and decorative blocks. Your construction project has now been given more latitude.

- Environmentally friendly - By using recycled resources like fly ash and slag, the machine can create blocks. This lessens the negative effects of your construction project on the environment.

- Easy to use - Even for beginners, operating the machine is not too difficult. This implies that operating the machine yourself will save your expenses on labour.

- Low maintenance - The machine requires minimal maintenance, which can help you save money in the long run.

- Durable construction - The machinery is made from durable materials which can help it last for many years.

How the machine works?

In order to form the concrete into blocks, a semi-automatic double cavity concrete brick and block forming machine uses compression and vibration. Concrete is mixed in the machines hopper before being put into a mould. The concrete is then distributed uniformly within the mould after being vibrated to remove air bubbles. The concrete is subsequently compressed by a hydraulic ram which forces it to assume the mould’s shape.

The steps for using the machinery are as follows->

- The hopper is used to mix the concrete before it is poured into the cavity of the mould.

- The concrete is distributed uniformly within the mould by vibrating it to remove air bubbles.

- The concrete is forced to assume the mould's shape by the hydraulic ram's compression of it.

- A curing bed is used when the block is removed from the mould and discharged.

- Before being used, the block must cure for a predetermined period of time.

The machine’s primary components involves:

- Vibrating table - The concrete is distributed evenly and air bubbles are removed from the mould by vibrating the mould.

- Mould - The block being made is in the form of a mould. To keep the concrete from sticking it is coated with a rubber or plastic covering and constructed of steel or aluminium.

- Hydraulic Ram - The concrete is compressed by the hydraulic ram, which causes it to assume the mould's shape.

- Control panel - The control panel directs how the machine operates. In addition to controls for the vibration and compression levels it contains buttons for starting and halting the machine.

All things thought out, a semi-automatic double cavity concrete brick and block building machine is a fantastic choice for organizations and individuals who need to fast and efficiently make high quality blocks.

Frequently Asked Questions

There are many things to think about when selecting a semi-automatic double cavity concrete brick and block making machine including the machine’s size, capacity, features, etc.

A variety of suppliers and including online sellers, brick making machine manufacturers, and construction equipment dealers, sell semi-automatic double cavity concrete brick and block forming machines.

The main drawback of using a semi-automatic double cavity concrete brick and block making machine is the higher initial investment cost compared to a manual brick making machine. Nevertheless the machine can result in financial savings over time by increasing productivity and lowering labour costs.

A semi-automatic double cavity concrete brick and block making machine may require different types of maintenance but it is necessary to routinely clean and oil the machine to keep it in excellent operating order.

A semi-automatic double cavity concrete brick and block production machine may produce bricks and blocks using a variety of concrete types however it usually uses cement, sand, gravel and water.