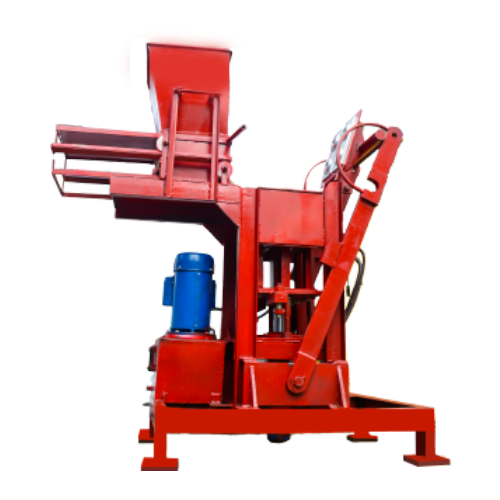

Best Pan Mixer Machine in India

Pan Mixer Machine with Blade

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

Pan mixer machine is a industrial machine used in big construction projects like Road making, Building making, Bridge making and etc

The function of this machine is to mix the concrete which is generally used in buildings and construction

Normally for a small construction project the builders can mix the concrete by traditional method as well but that way there is a high change of getting improperly mixed concrete materials. So It is always recommended to use a good Pan mixer to mix concrete for building your dream house.

FEATURES | SPECIFICATION |

|---|---|

Mixing Capacity | 380 Kg / Batch |

Total Power Required | 5 HP (Three Phase) |

Diameter | 5 ft |

Usages | Mixing Raw Material |

Process | Manual Raw Material |

Gear Oil Required | 20 Ltr |

Drive | with gearbox |

What Is a Pan Mixer Machine?

A pan mixer machine has a unique feature; while other concrete mixers may use a hopper or a mixing drum, it uses a rotating pan to mix the volatile ingredients. This pan is built from stainless steel and sports internal blades to perform the homogeneous mixture without breaking a sweat!

The Concrete pan mixer machine‘s various models have saturated the market, and you will come across variants ranging from small mixers to large ones that can mix concrete in bulk. Always remember that your choice of buying a pan mixer machine depends on the magnitude of your concrete requirement!

An electric motor typically represents the pan Concrete mixer machine‘s heart, although alternative power sources also exist (diesel engines). The motor lends energy to driving the pan to rotate at high speeds.

Buckle up! This article will focus on the concrete pan mixer machine‘s primary features, its advantages over traditional mixers, its how-to procedure, and its unique angle in revolutionizing the work pattern of the construction industry.

What Are the Key Features of the Pan Mixer Machine?

No product stays relevant in the market for long unless and until it brings crucial features to the discussion. The pan mixer machine is no stranger to this, as it delivers several properties in practical usage that make it a valuable commodity for construction projects.

First, the rotating pan represents the primary component of the mixer. There are blades inside this pan that assist in evenly mixing the concrete.

Some higher-end models offer the operator a heating mechanism to warm the pan. This nifty bonus is helpful in cold weather or when mixing materials that require a warm temperature.

Second, the concrete pan mixer machines pulls its operations with the inclusion of a motor that drives its core. While this motor is generally electric, there are diesel-powered variants as well.

Third, you will also come across models with a fitted water sprayer, which can add water to the concrete mixture. The sprayer can prevent the concrete from drying and cool the mixer’s temperature.

Most pan mixer Concrete machine options exist with automatic controls to regulate the mixing process while the operator can attend to other tasks. They also have transport wheels to move the mixer from location to location, effectively spreading the concrete distribution process.

Finally, all Concrete pan mixer machines have safety features to prevent mishaps or accidents. These features may vary from blade guards to emergency-stopping mechanisms and overload protection.

How Does the Pan Mixer Machine Work?

The mixing process is straightforward – it begins with loading all ingredients into the pan. Then, the operator starts the motor, which drives electrical power to the pan and rotates it with the internal blades.

When the blades work, they mix the ingredients to form the desired concrete mix. Remember that the mix’s speed and duration depend on the concrete’s quality and the project’s specific requirements.

When the mixing process is complete, the operator stops the motor, and the rotating pan halts. Operators carefully remove the readymade concrete and pour it into forms or over the desired surfaces.

Let us break down the pan mixer machine‘s how-to strategy in simple steps:

- 1. Load the ingredients (cement, sand, water, aggregates, etc.) into the pan.

- 2. Turn the motor on.

- 3. Allow the pan and blades to rotate according to site demands.

- 4. Stop the motor.

- 5. Tilt the pan to discharge the concrete onto wheelbarrows, buckets, or directly on a target surface.

While it’s relatively easy to operate a concrete pan mixer machine, there are some things you need to look out for to ensure its longevity and peak performance levels.

For example, clean the pan regularly and always use the right ingredients aligning with the mixer’s size. Avoid overloading it!

Also, avoid overmixing the concrete! You can lower its strength and make it a weak mixture, which operators must avoid while raising durable infrastructure.

Finally, operate the Concrete pan mixer machine in a well-ventilated area to avoid inhaling dust or other hazardous substances.

Where Is the Pan Mixer Machine Most Applicable?

Here’s where the pan Concrete mixer machine shines! This machine is applicable across many scenarios and has proven time and time again as a capable asset of producing fine-quality concrete without compromising on its quality and strength.

While concrete is its primary output, it can also make mortar and other materials for construction projects. It can lend assistance in composing several products like bricks, tiles, and concrete blocks.

One area where other mixers cannot lend assistance is to produce fertilizers, but the pan mixer machine is a pioneer in this process. It can prepare pesticides and other agricultural chemicals for crops and mix chemicals for several industrial applications!

It is ridiculous to assume a concrete mixer machine can assist in food processing, but this is what the pan mixer machines can do again! Bakers use this marvelous product to mix ingredients for food products, such as cakes, cookies, and bread.

Lastly, pan mixer machines are also used in laboratories to mix small quantities of materials for testing purposes.

What Are the Advantages of the Pan Mixer Machine?

The advantages of using a pan mixer machines are manifold. While traditional mixers exhibit one form of weakness over another, this machine is relentless in its operations, catapulting itself into a ‘cannot-do-without’ status in the construction industry.

Let us comprehend all its advantages in a simplified manner:

It delivers quick results and efficient mixing: The pan Concrete mixer machines never falters when the primary concern is about harvesting results on time. It’s a reliant machine for getting the work done without delay and reduces labor costs for large construction projects.

It is always consistent: Other mixers may compromise on the quality of the concrete mix, but you never have to worry if you are assigning a pan Concrete mixer machines to do your mixing process. It maintains a uniform quality to ensure the strength and durability of the newly-formed concrete.

It is relatively easy to use: It is a piece of cake operating this technical marvel! Hence, the pan Concrete mixer machines is applicable across many fields ranging from concrete sites to the agriculture sector and even bakeries,

It is robust: Manufacturers never compromise on the quality of the materials that make the pan Concrete mixer machine, so if you’re out looking for one, expect durability to come with the product!

It is cost-effective: Pan mixer machines are relatively inexpensive to purchase and operate compared to maintaining large concrete batching plants. They will save you precious money in the long run while sticking to the timeline of delivering high-quality concrete.

Overall, pan mixer machines are efficient, consistent, easy to use, built to last, and are a cost-effective alternative to other mixers. Some minor inconveniences exist, like its large and bulky frame models, while a few can also contribute to noise or dust pollution. Despite the disadvantages, construction endeavors emphasize the benefits of the concrete pan mixer machine because they far outweigh the cons.

Watch Video of our Pan Mixer Machine

Frequently Asked Questions

While other concrete mixers may use a hopper or a mixing drum, a pan mixer machine uses a rotating pan to mix the volatile ingredients. This pan is composed of stainless steel.

A pan mixer machine is efficient, consistent, relatively easy to use, durable, and resonates as a cost-effective alternative to expensive mixers!

The price ratios of pan mixer machines have a wide gap based on their make and model. Cheaper-end variants can start from around Rs. 50,000, while the higher models can go over Rs. 1,50,000.

Yes! Lotus Traders keeps an ever-full stock of all construction-related equipment, so expect to find us equipped with the best pan mixer machines available!

The mixing capacity of a pan mixer machine depends on its model, but you can expect an average of 380kg output per batch.

No, the pan mixer machine is a darling in the construction industry for its easy-to-use interface, so expect beginners to learn the working mechanism of the product in one to two hours.

Yes. The pan mixer machine is relatively easy to operate over other mixers. It has become a core equipment for other activities besides concrete mixing, like laboratory experiments, baking, pesticide production, etc.