Material testing equipment is essential for evaluating the quality, performance, and durability of substances used in road construction. These tools help engineers and quality control professionals assess critical properties such as viscosity, penetration, softening point, stability, and resistance to aging. Proper testing ensures that roads, highways, and pavements can withstand varying traffic loads, harsh weather conditions, and long-term wear and tear.

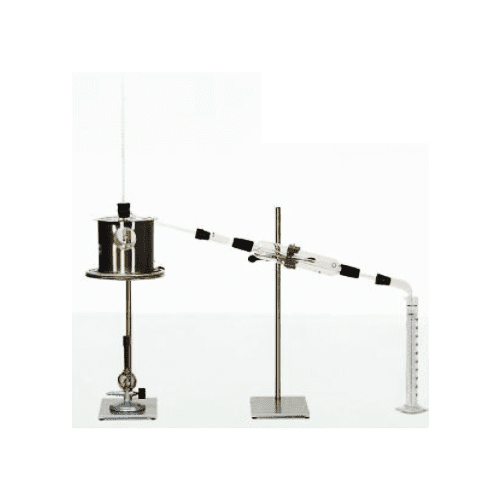

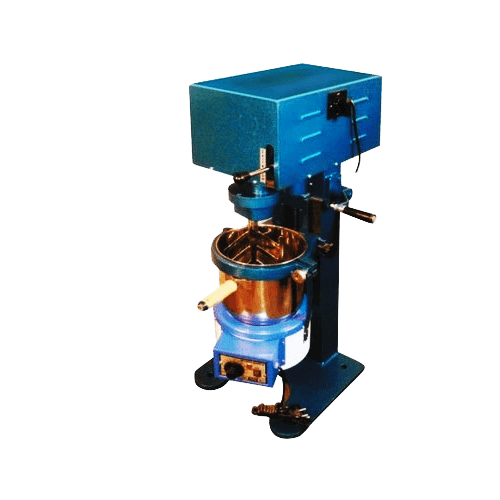

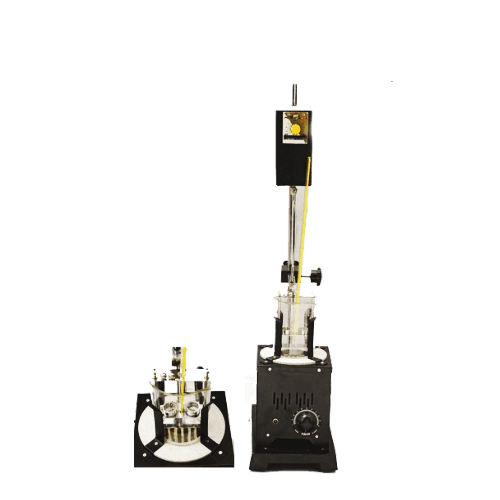

A variety of testing methods are used to analyze the physical and chemical characteristics of construction materials. For example, penetrometers measure hardness, viscometers assess flow properties, and softening point apparatus determines the temperature at which materials become pliable. Stability testing machines, such as the Marshall Stability Tester, evaluate load-bearing capacity, while aging simulators like the Rolling Thin Film Oven (RTFO) and Pressure Aging Vessel (PAV) replicate long-term environmental effects.

Conducting these assessments helps optimize mix designs, improve durability, and enhance safety by ensuring proper skid resistance and structural integrity. Additionally, high-quality materials reduce maintenance costs and extend the lifespan of infrastructure. By adhering to industry standards such as ASTM and AASHTO, construction teams can ensure compliance, leading to the development of stronger, safer, and more cost-effective road networks.

Reliable testing equipment plays a crucial role in the construction industry, ensuring the quality, durability, and performance of materials used in road projects. These tests assess the physical and chemical properties of paving materials, which are essential for roads, highways, and pavements to withstand traffic loads, environmental conditions, and long-term wear and tear.

Key Benefits of Material Testing:

Ensures Strength & Stability – Proper evaluation helps determine the structural integrity of paving materials, preventing premature failures such as cracks, potholes, and surface deformation. By analyzing strength and stability, engineers can select the best composition for high-traffic roads and highways.

Improves Safety – Roads require adequate skid resistance and load-bearing capacity to ensure vehicle and pedestrian safety. Testing processes help assess these factors, reducing risks associated with surface failures, uneven pavement, or insufficient traction.

Enhances Longevity & Reduces Maintenance Costs – High-quality materials ensure that roads remain durable for extended periods, minimizing the need for frequent repairs. Proper assessments help prevent costly infrastructure failures, ultimately saving time and money.

Ensures Compliance with Industry Standards – Government regulations and industry guidelines require specific material properties for road construction. Testing methods help ensure compliance with standards set by ASTM, AASHTO, and other regulatory bodies, preventing legal issues and ensuring high-quality construction.

Optimizes Mix Design for Different Conditions – The performance of road-building materials varies depending on factors such as temperature, traffic load, and environmental exposure. Through testing, engineers can fine-tune material composition, ensuring optimal performance under specific project conditions. This results in roads that can withstand diverse climates and heavy usage without deteriorating quickly.

In conclusion, advanced quality control methods are essential in the construction industry. They help create long-lasting, safe, and cost-effective roads by ensuring material reliability, optimizing mix design, and meeting industry standards. Investing in proper testing improves infrastructure quality, enhances public safety, and reduces maintenance costs, leading to more durable and sustainable road networks.

Key Features:

- Precision & Accuracy – Provides reliable test results for assessing material quality.

- Durability – Designed to withstand heavy-duty industrial applications.

- Automated & Digital Testing – Advanced systems offer real-time data recording and analysis.

- Wide Testing Range – Capable of measuring viscosity, penetration, softening point, stability, and aging properties.

- Compliance with Standards – Meets ASTM, AASHTO, and other global construction regulations.

- Portability – Some models are compact and easily transportable for on-site assessments.

Benefits:

- Ensures material quality by helping in selecting the best mix for road construction.

- Enhances road durability by preventing common surface issues like cracks, potholes, and early wear.

- Reduces maintenance costs as high-quality components contribute to long-lasting infrastructure.

- Increases safety by ensuring adequate skid resistance and stability under various traffic loads.

- Optimizes construction efficiency by assisting engineers in fine-tuning material composition for different environmental conditions.

By utilizing advanced testing methods, construction teams can achieve stronger, safer, and more cost-effective roadways, ensuring long-term performance and compliance with industry standards.

Recommend Products

One Bag Concrete Mixer Machine

Manual 4 Cavity Brick Machine

Egg Lying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator