New Laboratory Concrete Mixer Machine, Small but Powerful one

So many concrete mixtures exist in the modern construction industry, yet each differs from the rest with unique properties. The same reputation applies to the laboratory concrete mixer machine, which has stood its ground throughout the competition to introduce itself as one top-level equipment in construction projects for beginners and veteran customers.

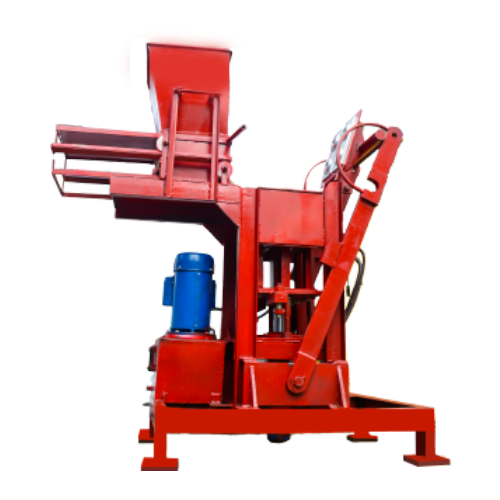

Laboratory Concrete Mixer Machine

- Factory original quality for less.

- Direct replacement.

- Installation is identical to factory unit.

- No vehicle modifications required.

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

It is a Laboratory Concrete Mixer best use in laboratory.

The function of Laboratory concrete mixer is to make fine mixer of concrete.

FEATURES | SPECIFICATION |

|---|---|

Batch Capacity | 80 Kg / Batch |

Power Motor | 0.78 KW |

Usages | Mixing Raw Material |

Driven By | Motor With Gear Box |

Packing | In Cartoon |

What is a Laboratory Concrete Mixer Machine?

The laboratory concrete mixer machine usually works best when site engineers have to mix small concrete batches strictly for evaluation or testing purposes in a sterilized laboratory environment.

Its primary function is to facilitate researchers or engineers to understand homogeneous mixing in a more elaborate process and accurately measure specific quantities of materials without any hindrance or complications. These materials are abrasive and can range from cement to aggregates and sometimes additives or admixtures.

In other words, the laboratory concrete mixer machine can assist in the simulation of concrete so that it is applicable for practical use in real-world construction projects.

While traditional industrial-scale concrete mixers occasionally take up a lot of space, the laboratory concrete mixer is a compact product, so it is rarely surprising to see these machines lined up in laboratories or research institutions for testing and development. Researchers work on exploring various factors with the aid of this concrete mixer, such as evaluating the strength, durability, workability, and setting timeline of the concrete. One simple cannot negate its scientific importance!

The laboratory concrete mixer machine usually comes equipped with a mixing drum, blades, or paddles to implement agitation and mechanisms to control the rotation speed and the mixing time.

The resulting concrete mixture is not for public use. Instead, it can support further experiments for various tests, including compression and slump tests. Thus, the laboratory concrete mixer machine helps researchers assess its suitability for specific applications and further optimize concrete mix designs.

Table of Contents

The Key Features of the Laboratory Concrete Mixer

The key features the laboratory concrete mixer machine provides for its users vary depending on the make and model. But, it is easy to distinguish them from other products because of a few standard features you will find across all their variations.

- First → their mixing capacity is severely limited! Compared to large industrial mixers, they are small, so their mixing potential is small, too. Potential customers should watch out for the overall mixing capacity of the laboratory concrete mixer if they do not want to make a hard choice!

- Second → you will find a laboratory concrete mixer equipped with mixing blades or paddles affixed to its mixing drum or container to ensure uncompromised quality in the active mixture. This precise control over the rotation speed and mixing timeline allows researchers to replicate ideal mixing conditions and further speculate their effects on the resulting concrete.

- Third → accuracy, adaptability, and durability are other prominent features the laboratory concrete mixer can boast about. Some models may allow the researcher with brilliant adaptability for testing different types of construction materials beyond just concrete, which contributes to expanding their versatility.

- Fourth → data collection is an integral asset to constant innovations in any technological industry, and the laboratory concrete mixer machine serves its dutiful purpose in this criterion. The most premium models offer advanced logging capabilities, allowing researchers to record and loop mixing parameters for enhanced laboratory analysis.

- Fiftly → there cannot be a reliable laboratory concrete mixer available if it cannot measure up to relevant industry standards! The machine must comply with all safety rules and operating regulations provided by the construction industry to ensure the accuracy and validity of testing results.

The Applicable of the Laboratory Concrete Mixer

So, where is the laboratory concrete mixer most efficient? It’s hard to read the truth, but this machine is not applicable for commercial or development-oriented usage.

It’s laboratory equipment by design, which labels it fit for applicability under the industry’s top engineers and researchers. They work with the lab mixer to fine-tune concrete quality and test different combinations of materials to achieve more robust results in speed, efficiency, and durability.

Quality control is another crucial factor supplementing the laboratory concrete mixer machine, ensuring the concrete produced on construction sites meets specific standards. Potential issues can already undergo systematic elimination before the mixed concrete is made available for site usage.

The concrete also undergoes several material testing procedures that check for its compressive strength testing, slump testing, and shrinkage testing. It becomes easier to derive data from the laboratory concrete mixer machine regarding the performance and characteristics of the concrete mixture by following up with these tests.

Admixtures and additives are a different breed! Concrete is usually a robust component, but to further solidify its rigidity, the industry makes calculated use of several abrasive materials in the mixing process. Laboratory concrete mixer machines smoothen this process by allowing controlled testing of these components to determine their impact on the final product.

One engaging area the laboratory concrete mixer machine excels at over other mixers is its ability to be a powerful tool in educational settings. Students can learn about concrete mixing designs, construction material science, and testing methodologies with the machine. Researchers may use the laboratory mixer to teach about concrete specimens for testing the structural behavior of various elements, such as beams or columns, under extremely well-supervised and controlled conditions.

Are there any lingering issues on a construction site over the quality of the concrete? Fret not; the laboratory concrete mixer immediately transforms here into a time saver! It can replicate the conditions and eliminate potential causes of problems in the concrete mix.

Advantages of the Laboratory Concrete Mixer Machine

A laboratory concrete mixer machine offers several prime advantages over other mixers, effectively enhancing the output of concrete production. Some of the key benefits from a lab mixer include:

Precise Mixing Control: The laboratory concrete mixer allows minute control over the mixing timeframe and always delivers consistent and reproducible results. This factor plays an unparalleled role in accurate testing and experimentation.

Small Batch Sizes: These mixers have undergone industrial standard procedures to usually handle smaller batch sizes, which is ideal for research and testing purposes rather than real-world construction projects.

Customization Mix Designs: Researchers can work on different proportions of materials to develop and perfect concrete mix designs in the comfort of their laboratories.

Data Accuracy: Laboratory concrete mixer machines constantly strive to bring technological advancements to the industry, and they contribute by precisely measuring and controlling mixing parameters. Tests are more conductible and results-driven as a result.

Reduction in Material Wastes: Since laboratory concrete mixer machines handle comparatively smaller batches, there is less material to waste during the experimentation and testing phases.

Time Efficiency: Researchers can conduct multiple tests and experiments within a shorter time frame, thanks to the controlled and efficient mixing process inside the laboratory concrete mixer machine.

Flexibility: Laboratory mixers are apt for several tests that may not align with concrete production. They can also withstand specialized experiments involving various materials and additives.

Overall, a laboratory concrete mixer machine‘s primary goal is to contribute to advancing construction material science, improve industrial construction practices, and develop more sustainable and efficient concrete mixtures. The benefits do not reach a blockade, for there are many more! They bring educational value to the table, mitigate risk factors, optimize the performance of other concrete mixers, and work as a cost-effective solution for research and development.

How Does the Laboratory Concrete Mixer Work?

Finally, we have reached the billion-dollar question – how does a laboratory concrete mixer machine operate? It operates by providing a stable environment for accurately mixing small concrete batches.

First, the operator must ensure the mixing drum is clean and does not contain any residue from previous fixes. Early preparation is paramount, so assorting materials like cement and additives for the upcoming mixture is necessary.

Second, after opening the mixing drum’s loading port or door, the operator adds the required materials into the container while adhering to standard safety rules.

Third, the operator activates the mechanism after loading the materials into the laboratory concrete mixer machine‘s drum. The added materials interact with blades or paddles and get smoothened into a liquid texture, giving essence to the formation of finely blended concrete. Alternating tests or mix designs may require varying mixation intensities, which is possible by increasing or reducing the velocity of the blades.

Fourth, it’s easy to think the process is over, but there’s no concrete mixture without assigning a regulated timeframe for it to occur! Hence, a mixing time gets allotted to the process occurring inside the laboratory concrete mixer machine, which can vary depending on factors such as the materials, the intended application of the concrete, and the required properties. Also, constant supervision is necessary if the operator wants a uniformly blended mixture that does not compromise consistency and homogeneity.

Fifth, after the mixing process ends, the operator shuts down the laboratory concrete mixer machine and discharges the mixed concrete into containers or molds. He does not do it manually; industries offer mechanisms for tilting or rotating the drum to complete this process.

Sixth, researchers opt for sample collection. Depending on the purpose of the test or experiment, they collect samples of the mixed concrete for further testing and analysis. These samples can contribute to assessing properties like compressive strength, force absorption, and longevity.

Seventh, it’s time to clean the mixing drum again! Overtime use of the laboratory concrete mixer machine without proper and regular maintenance can reduce its long-term performance and output quality.

A final and optional step is prevalent in the premium lab concrete mixer models, where they provide advanced logging or recording features. Data collected from these logs can vary across criteria ranging from rotation speed to mixing time.

What Makes the Laboratory Concrete Mixer Unique?

The laboratory concrete mixer machine deviates from other concrete mixers primarily in size, capacity, precision, and intended use. Its uniqueness lies in its competitive accuracy in handling small batches of concrete mixing. It also maintains a controlled mixing environment for various tests and experiments, something other concrete mixer machines lack as an advantage.

It emboldens testing and research, offers versatility for conducting other mixing processes, and becomes an educational companion for students in the related field. A simple definition underlying the laboratory concrete mixer machine‘s role is that it is an asset for researchers, scientists, and educators, a trait that other construction mixers do not inherit.

Conclusion

The laboratory concrete mixer machine has become an indispensable cornerstone within the construction industry. It does not carry the load of building infrastructure from the front-lines (we’re talking about construction sites here) but streamlines the working potential of other traditional concrete mixers by researching and improving their mixing quality. This machine serves as a testing hub where engineers, researchers, and scientists can meticulously study the properties of concrete mixtures by replicating real-world conditions and manipulating various factors. Its profound impact spans research, quality control, innovation, and education, establishing it as an instrumental force in driving the construction industry forward!

Lotus Traders deals in several products associated with construction, and we are proud to assure you we have the best laboratory concrete mixer machines your money can buy. We also deal in many other traditional cement mixers like one-bag concrete mixer machines, pan mixer machines, concrete mixer machines with lifts, color mixer machines, etc.

Visit us today to browse our catalog of the finest industrial equipment and take the first step toward making a healthy and wise decision for your upcoming construction project!

Watch Video of our Pan Mixer Machine

Frequently Asked Questions

A laboratory concrete mixer is used for educational and research purposes to better evaluate the quality of concrete through constant research and development. They are not appropriate for use in practical construction sites.

The price of a laboratory concrete mixer begins from the Rs. 28,000 mark, but higher models can charge up to more than Rs. 50,000.

Do you have laboratory concrete mixers in your shop?

While there is not much difference between the models of laboratory concrete mixers, higher variants come with premium features like advanced logging capabilities and analysis patterns.

While there is not much difference between the models of laboratory concrete mixers, higher variants come with premium features like advanced logging capabilities and analysis patterns.

A traditional laboratory concrete mixer can load eighty kilograms per batch. This ratio may vary based on make and model.

While laboratory concrete mixers are relatively easy to operate, they are not for general construction sites. Their expertise and usage are for site engineers or researchers striving to improve the concrete mixing quality.

While laboratory concrete mixers are relatively easy to operate, they are not for general construction sites. Their expertise and usage are for site engineers or researchers striving to improve the concrete mixing quality.

While laboratory concrete mixers are relatively easy to operate, they are not for general construction sites. Their expertise and usage are for site engineers or researchers striving to improve the concrete mixing quality.