Best Double Beam Surface Vibrator in India

The double-beam surface vibrator’s compaction level is top-notch, leaving projects with little room for imperfections or errors!

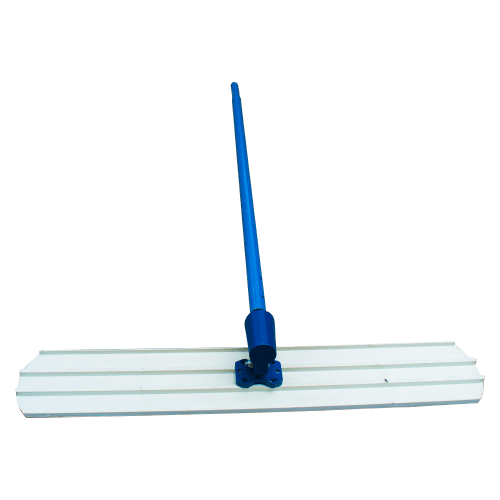

Double Beam Surface Vibrator

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Beam Spacing Bsp | 300 mm |

Height of Beam | 100 mm |

Standard Lengths | 4.5 m |

Weight Of The Beam | 55 & 60 KG |

Motor | 1.56 kw / 440volt |

Motor Speed | 2900 RPM |

What Is a Double Beam Surface Vibrator?

The double-beam surface vibrator has reached an unprecedented cornerstone of excellence; it is the industrial pick for civil engineering and construction sites to ensure perfect concrete compaction. Large concrete structures such as bridges, highways, and buildings simply cannot exist without the vibrator!

Two parallel steel beams adorn the frame of the vibrator and remain attached to an engine. These beams contain vibrating units or eccentric weights for generating high-frequency vibrations.

This article will explain why experts prefer the double-beam surface vibrator for uncompromising compaction and their overall contribution to improving the strength and longevity of concrete structures. Let us go through all the details!

Table of Contents

What Are the Key Features of the Double Beam Surface Vibrator?

The double-beam surface vibrator exhibits many features to propel itself into an elite status in the construction industry. Its most typical characteristics across all its models are:

The dual beams: The ‘double’ in the equipment’s name stands for two parallel beams to distribute even vibrations across the concrete surface. Manufacturers have built it in this method to ensure uniform compaction.

The high-frequency vibrations: These frequencies are not trivial; they exhibit high frequency, typically ranging between 9,000 to 12,000 per minute (VPM). These frequencies play an undisputed role in removing air bubbles from the concrete.

The adjustable settings: Modern models offer adjustable settings to tweak the vibration intensity and frequency. This benefit is crucial for the double-beam surface vibrator to suit different project requirements.

The various engine options: Different engine models exist for the double-beam surface vibrator; they run on electricity, gasoline, or diesel. The wise choice of selecting one engine depends on the availability of the power source and the mobility applicable to the project.

The ergonomic designs: Modern models have undergone specific manufacturing protocols to focus on comfort and safety for operators. You will find today’s offerings with ergonomic handles and vibration-dampening technology to reduce fatigue during extended use.

If this isn’t enough, you will find a host of additional features in the double-beam surface vibrator ranging from portability to optional attachments and world-class safety features. Overall, all these qualities make the machine appropriate for achieving high-quality concrete surfaces!

How Does the Double Beam Surface Vibrator Work?

The double-beam surface vibrator is a widely versatile tool, offering its capabilities to a host of construction projects. Its high-frequency vibrations are ideal for settling concrete, making it the undisputed tool for installing robust foundations for aspiring architecture.

Here’s a streamlined process explaining how the machine works:

First, it’s essential to correct the positioning: The initial step is to place the double beam surface delicately over the freshly poured concrete. Operators do this typically on top of formwork or a framework that defines the shape and dimensions of the concrete structure.

Second, start the engine: The operator brings the vibrator to life by turning on the engine. Note that the engine’s power source can vary – it runs on electricity, gasoline, or diesel fuel. Electric vibrators are paramount when the power source is abundant, but diesel-powered models offer mobility in remote or outdoor construction sites.

Third, the machine generates vibrations: The eccentric weights comprise the heart of the double-beam surface vibrator! These weights are deliberately unbalanced, causing the beams to vibrate rapidly when the engine is on. As these weights rotate, they give rise to centrifugal force, resulting in high-frequency vibrations.

Fourth, the vibrations get transmitted: The vibrations from the eccentric weights get transmitted through the beams to the concrete surface. The operator has to hold onto the handles to guide it smoothly across the concrete. As the vibrator moves, the vibrations penetrate through the concrete, causing it to settle and compact.

Fifth, the compaction takes place: This is the role for which the double-beam surface vibrator exists! As the high-frequency vibrations continue to eliminate air voids, the compaction delivers unparalleled structural integrity and strength to the finished concrete structure.

Sixth, additional smoothing happens: Besides compaction, the regular vibrations also assist in smoothing the concrete surface. Level and even finishes are necessary to indulge pleasing aesthetics and reduce further construction work like flooring or laying tiles.

Seventh, the operator needs to move the machine: To ensure an even finish across the entire surface, the operator has to move the double-beam surface vibrator from one end to another. It is worth noting that the movement speed and time spent over one area can yield different target results.

Finally, it’s time to pack up: Once the entire surface has undergone compaction, the operator turns off the vibrator!

Where Is the Double Beam Surface Vibrator Applicable?

The double-beam surface vibrator has provided its usefulness in several complimentary scenarios that demand critical surface finishing. Modern architecture cannot exist without its effectiveness, as it offers unparalleled efficiency in making:

Slabs and floors: The machine creates finely compacted concrete slabs and floors in buildings, industrial facilities, and residential structures. These smooth surfaces provide aesthetically pleasing designs for the naked eye to observe and enjoy!

Roads and highways: Even roads and highways are the beacon of a country’s productivity. It is crucial to deliver proper compaction to increase the longevity and load-bearing capacity of the road surface.

Bridges and overpasses: The double-beam surface vibrator is essential for compacting the concrete into various structural components, including bridge decks and supports, to ensure the structural integrity and durability of the critical transportation structures.

Tunnels: Tunnels take advantage of the vibrator to compact concrete linings and walls.

Dams and embankments: The concrete inside the dam’s infrastructure has to be compact because it must be able to solidify the dam’s stability and water containment capabilities.

This list is not the end of things; the double-beam surface vibrator is also crucial for holding retaining walls, constructing sleek airport runways, erecting robust foundations, raising culverts, drainage channels, and stormwater management systems, etc. Overall, it’s construction equipment that aligns with contrasting needs!

What Are the Advantages of the Double Beam Surface Vibrator?

The advantages typically outline the importance of a product, and in this case, the double-beam surface vibrator is no different matter. Its prime benefits are manifold, making it a popular choice among construction enthusiasts for applying the machine’s capabilities to their projects.

Here are the advantages all double-beam surface vibrator models provide without discrimination:

Improved concrete compaction: The machine is highly proficient at compacting concrete, eliminating air voids, and ensuring the mixture has undergone dense packaging.

Uniform compaction: Consistent compaction is another benefit it brings to the discussion table, as the dual-beam design of the vibrator epitomizes even uniformity throughout the entire surface area.

It saves time: Using the double-beam surface vibrator reduced the time required to complete complex compaction and finishing tasks, allowing for faster project completion.

It provides smooth surface finishes: Smooth and even concrete surfaces make for the undisputable aesthetic appeal and the conventional luxury of applying additional finishes or flooring materials.

It reduces manual labor: The proficiency of the double-beam surface vibrator reduces the need for extensive manual effort, thereby reducing labor costs and improving worker safety.

Other advantages lining up to justify the double-beam surface vibrator’s existence are the inclusion of higher productivity, versatility, enhanced durability, improved structural integrity, consistent quality, etc.

In the modern industry, the double-beam surface vibrator has taken the role of a pivotal tool to deliver complete construction and concrete work, offering profound importance in achieving superior concrete quality and structural integrity. If you’re looking for one that aligns with your next project’s goals, we have the best double-beam surface vibrator models available which will comply with all your requirements!

Lotus Traders has contributed to the construction industry for a long time and will continue to do so because of our goal to change the economic landscape of India. Visit us today to browse through our most exclusive products and take advantage of our mind-blowing offers!

Frequently Asked Questions

The double-beam surface vibrator’s prime purpose is to ensure perfect concrete compaction. Large concrete structures such as bridges, highways, and buildings simply cannot exist without the vibrator!

The double-beam surface vibrator’s price range typically hovers between Rs. 14,000 to Rs. 45,000, with the exquisite variants demanding prices reaching the higher spectrum.

Lotus Traders has all the models related to the double-beam surface vibrator, so if you’re looking to buy one, visit our shop today for a personal browsing experience!

Yes, we have the double-beam surface vibrator, ranging from the budget-oriented variants to the highly sophisticated ones.

The double-beam surface vibrator improves concrete compaction, saves time, provides smooth surface finishes, reduces manual labor, etc. Avail all these benefits in one product!

While it is relatively not rocket science, the double-beam surface vibrator demands proper industrial training, so operators have to follow up with the preset guidelines before using it.

Concrete Mixer Machine With Lift

Manual 4 Cavity Brick Machine

Egg Laying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator