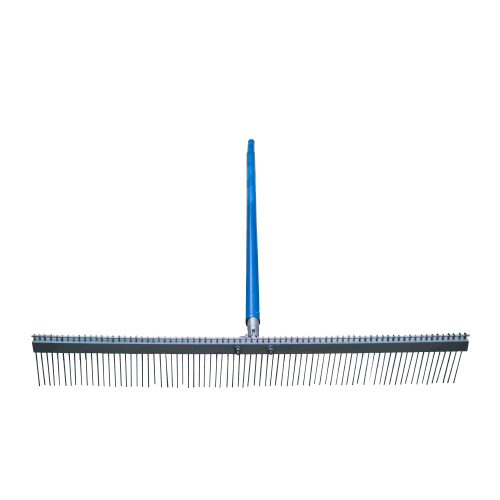

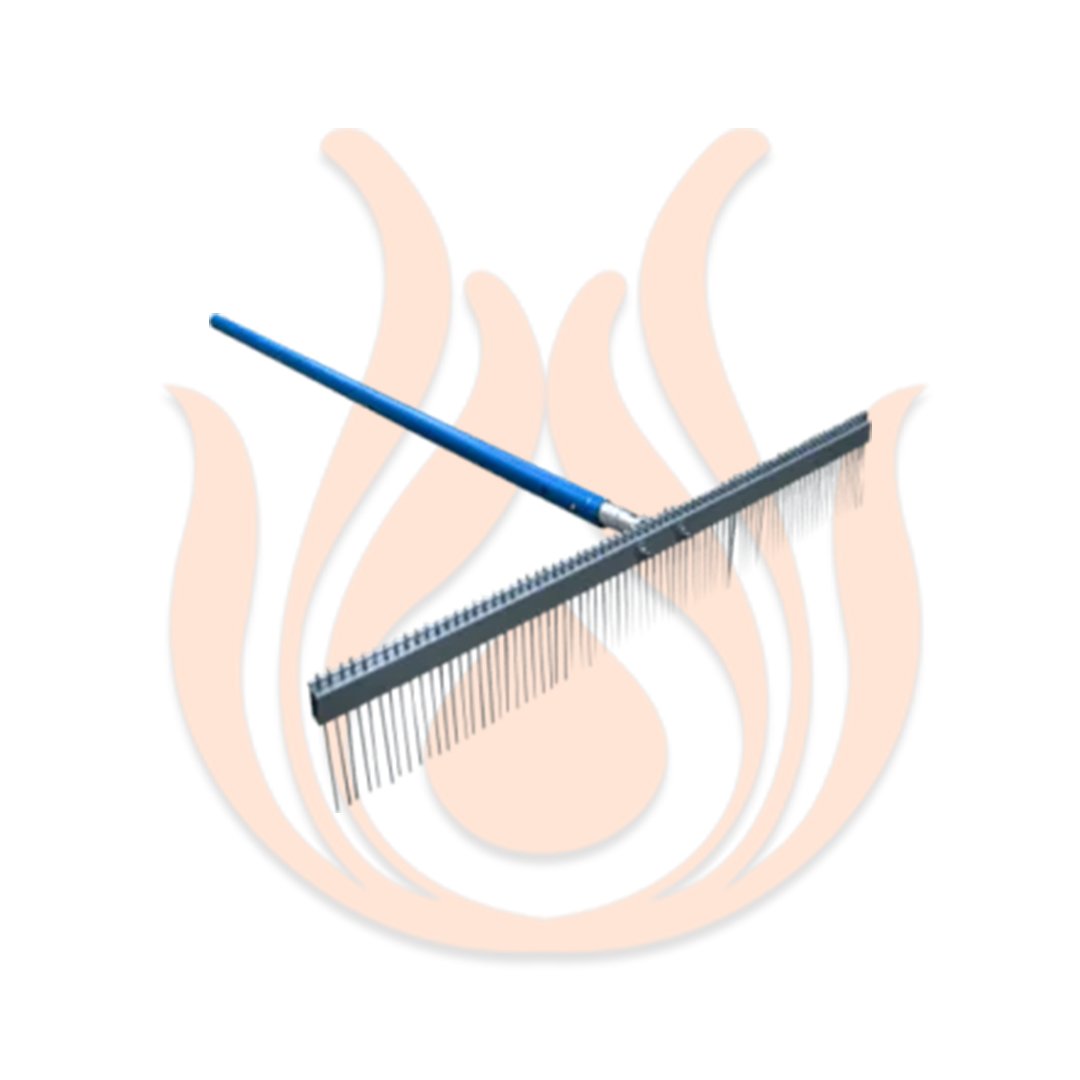

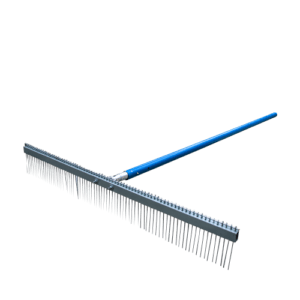

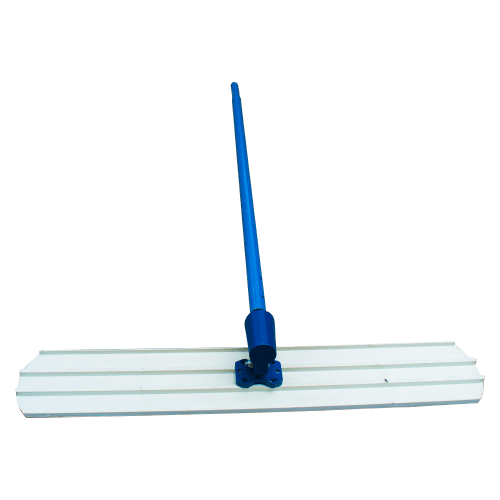

Texture Brush

Texture Brush

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURES | SPECIFICATION |

Size | 1 mtr |

Distance Between Strings | 15 mm |

Handle | 9 mtr |

Process | Manual Hand |

What Is a Texture Brush?

In the construction industry, the texture brush has become indispensable for applying desired texture to surfaces like walls and ceilings to alleviate the finishing process. This brush typically dominates in drywall and plastering work and is often combined with texture compounds or materials to achieve different surface finishes and patterns.

The texture brush epitomizes the durability of a project, but it also raises its aesthetic bar for onlookers to appreciate the finished product. While there are many decorative tools for efficient use in the construction industry, skilled workers prioritize the brush to add character and style to interior and exterior spaces.

This article aims to elevate the texture brush‘s distinct features, its advantages in complex projects, and its paramount importance in grand construction endeavors. Hop on as we will go through the most acute details!

Table of Contents

What Are the Key Features of the Texture Brush?

The texture brush has many models – expect them to vary by make and design and witness their dependence according to the texture application and the desired finish. However, some identical features are prevalent, such as:

Contrasting brush designs: These designs are different and unique, like various bristle patterns, shapes, and sizes. The most common variants include bristle clusters, stippling patterns, or irregular bristle shapes.

The dedicated bristle material: The bristle cannot be delicate; it has to be resilient and durable, so expect its composition to be of synthetic fibers or natural materials like horsehair. The choice of the bristle can affect the brush’s long-term life!

The sturdy handle: The texture brush needs the support of a handle to provide a comfortable grip and precise control during application. These handles vary; the material constitutes wood, plastic, or metal.

The bristle length: The bristles are long or short depending on the requirement of the texture pattern. The longer ones create deeper, in-flow strokes, while shorter ones assist in finer finishes.

The proper weight ratio: The texture brush must avoid being overweight; they must be balanced enough to facilitate ease of use and reduce fatigue if depended upon for extended periods.

Compatibility with textures: There are varying models of the texture brush because it needs to provide versatility for alternating texture models, such as plaster, stucco, or ceiling texture compounds.

The list of models that have saturated the market is overwhelming! However, check firsthand which brush will be compatible with the material you intend to use it on!

How Does the Texture Brush Work?

The texture brush follows a streamlined operation process that is convenient to understand but requires dedication and patience to master the desired surface area. Here is the most effective how-to extract to getting the best out of this nifty product:

First, the surface needs preparation. It is imperative to clean the surface before working on it! Unwanted dirt, dust, or debris can prevent the texture brush from applying a suitable primer or base coat, specifically for drywall or other porous surfaces.

Second, the texture material needs preparation. Manufacturers prepare well-established guidelines to prepare the texture material beforehand. Various procedures may follow, such as mixing the required material with water or other additives to achieve the desired consistency.

Third, it’s time to load the brush. The operator loads the texture brush with the prepared text material. This step is a simple process; it involves dipping the brush into the bucket holding the texture or using a separate tool (trowel) to apply the material over the brush’s bristles.

Fourth, the application occurs. Here comes the most crucial part – applying the texture over the surface according to the desired texture pattern! The most common methods include poking the surface with the brush, creating circular or wavy patterns, dragging the brush across the surface, etc.

Fifth, follow up on any required texture adjustments. If there are target requirements, the operator may need to adjust the depth and appearance of the texture by altering the pressure, angle, or external factors.

Sixth, maintain blending and consistency. It is crucial to blend the texture patterns if the end goal is to create seamless or consistent textures across larger surfaces. How is this achievable? The brush needs constant overlapping, or a trowel or roller can assist in evening out the texture.

Seventh, it’s drying time! Once the applying procedure halts, the texture needs sufficient time to dry or set. Do not touch or disturb the texture surface during the drying time.

Finally, remember to clean. Many texture brush owners consider this an optional step, but it’s the most underrated one! If the brush is not cleaned regularly through thorough rinsing, the residue material can cause the bristles to harden and impact future performances.

Where Is the Texture Brush Applicable?

You cannot underestimate the applicable strengths of the texture brush; it is essential in many contexts where site supervisors focus on unparalleled texture finishes. These brushes bring architecture to life by adding visual interest and alleviating the depth and texture of walls, ceilings, and other surfaces!

Here are the most common usage-case scenarios for the texture brush:

Interior wall finishes: Walls look bland if they do not adhere to an aesthetic standard. The texture eliminates this ugliness by executing well-crafted texture finishes resonating with different styles and patterns.

Ceiling texturing: Many ceilings need texturing to hide spots or imperfections and to create a distinctive look. Texture brushes can create unique ceiling textures, like popcorn, knockdown, or stippled finishes.

Repairing drywalls: It’s natural to expect walls to dry out over time. The texture brush can add life to the dry spots by seamlessly blending the old and new textures.

Finishing exterior stuccos: Exterior walls or facades can use the brush to apply stylized plaster or other robust finishes to enhance the durability and appearance of buildings.

Decorative finishes: There are infinite areas in the construction industry that require decorative finishes! Some examples of stylized techniques include faux painting, fresco-style textures, or textured patterns for piquing visual interest.

Restoration of historical works: Tourism plays a huge part in boosting a nation’s economy, so prioritizing the preservation of cultural buildings is crucial to maintaining historical accuracy.

These usage-case scenarios are not the end of the list; other areas where the texture brush is a dependable tool are in creating attractive interior designs for commercial spaces, children’s bedrooms, exterior landscaping features, artistic and custom projects, etc.

What Are the Advantages of the Texture Brush?

The texture brush has been in the construction business for a long time. It has undergone wide adoption by contrasting cultures to achieve peak infrastructure visuality while providing uncompromised rigidity to them. Let us extrapolate all the advantages most concisely by preparing a streamlined list below:

It enhances surfaces: Textured finishes alleviate the dull look of a wall or ceiling into a vibrant one. They can also hide imperfections, such as visually unattractive cracks or blemishes.

It provides pleasing varieties: The texture brush has many models to accommodate flexibility and provide contrasting textures. No two surface areas will ever look the same!

It enhances visual interest: Specially-textured surfaces add depth and accelerate visual integrity to interior and exterior spaces. Expect them to break up monotonous flat surfaces, making rooms and facades more engaging and dynamic!

It promises durability: It may look like the texture brush prioritizes physical appearance, but it also makes finishes more durable and resistant to wear and tear.

It absorbs sound: Particular texture patterns exist to improve acoustic properties by reducing sound reverberation and echo. This factor is often beneficial in commercial spaces or rooms where efficient sound control is paramount.

Many other benefits are entailing the texture brush, such as matching existing textures by overlapping them, providing creativity for artistic expressions and thoughts, and increasing overall property value by enhancing their appeal factor!

While the texture brush is indispensable to visually ambitious endeavors, one should use it skillfully and appropriately, as improper application can lead to uneven or undesirable results. Fret not; the industry’s experienced professionals understand the nuances of using texture brushes to achieve the desired outcome and maximize the benefits they offer!

Do you want to buy a texture brush? Lotus Traders has a catalog of the finest models. We aim to satisfy your artistic needs while maintaining the structural integrity of your project. Besides the texture brush, we have other construction-related equipment like earth compactors, groove-cutting machines, vacuum dewatering pumps, etc.

Visit our shop today to have a more in-hand experience!

Concrete Mixer Machine With Lift

Manual 4 Cavity Brick Machine

Egg Laying Type Block Making Machine

Double Wheel Trolley

Needle Vibrator