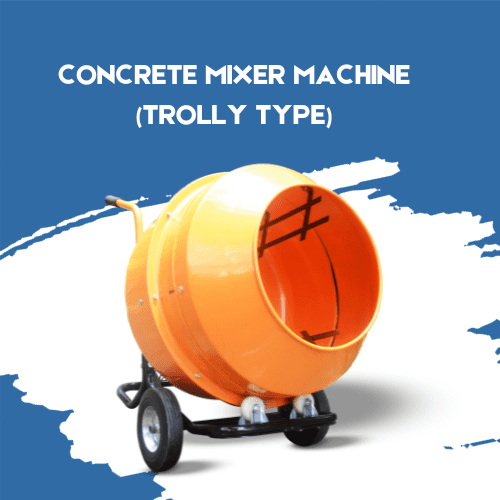

New Trolley Type Concrete Mixer Machine at an affordable price

Trolley Type Concrete Mixer Machine

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

What is the Trolley-Type Concrete Mixer Machine?

The trolley-type concrete mixer has made industrial waves for all the right reasons; it is a nifty concrete mixing machine typically applicable for small to medium-sized construction projects. There is a drum or a container of sorts that thoroughly mixes the concrete. This drum stays affixed atop a wheeled frame or trolley.

The trolley is the most conventional part of this unique mixer, allowing easy transportation to locations from one corner of a construction site to another.

Expect convenience for complicated tasks like preparing small concrete batches or pouring concrete footings with the help of the trolley-type concrete mixer!

Table of Contents

What Are the Key Features of the Trolley-Type Concrete Mixer?

The key features of a trolley-type concrete mixer machine vary by make and model, but most variants come with the same features that distinguish them from other traditional mixers. These features include, but are not limited to:

Uncompromising Portability: It’s got wheels! The trolley design accelerates the transportation time in the blink of an eye, leaving you to focus on other aspects of the project. The wheel or trolley frame must be strong enough to carry the mixing drum’s weight.

Electric or Gasoline-Powered Engine: There are typically two power sources running the heart of the trolley-type concrete mixer machine – it either runs on electricity or gasoline, leaving you with flexible options.

Variable Mixing Drum Capacity: No two mixers exhibit the same properties, so expect the mixing drum’s capacity to have different values. Small models support DIY projects, while larger ones contribute to more extensive concrete mixing tasks.

Prime Durability: The construction landscape demands a straining toll. Thus, manufacturers make the trolley-type concrete mixer machine robust enough to survive all rigors while delivering non-stop high-quality concrete batches. The mixer comprises sturdy materials, ensuring longevity and peak efficiency.

Various external factors make for features relating to the trolley-type concrete mixer machine, including the volume of concrete required and the power source available to maintain a high-functioning state. Proper maintenance and safe operation procedures also matter!

How Does the Trolley Type Concrete Mixer Work?

A trolley-type concrete mixer follows a streamlined process of creating homogeneous continuous concrete batches. Let us understand how it works by layering out a step-by-step overview:

First, the operator loads the ingredients. The required materials for the concrete mix inside the drum usually include cement, water, sand, and aggregates. Their exact proportions always depend on the assigned project’s specific mix design.

Second, start the mixer. Turning the trolley-type concrete mixer machine on varies based on its power source. The operator can switch the electric motor on or start the gasoline engine.

Third, the rotating drum undergoes its procedure. The heart of the mixer is the rotating drum, without which no concrete mixer will work. A few blades or paddles exist inside this drum that assist in agitating the materials and promote concise mixing.

Fourth, the mixing process occurs. The drum’s consistent rotation causes the ingredients to tumble and combine. A fine concrete paste comes to life as the cement’s raw particles blend with the water.

Fifth, adjust the mixing speed according to project requirements. The fancier trolley type concrete mixer models allow the operators to adjust the mixing speed and achieve site-specific quality. Slower speeds produce wetter mixes, while higher velocities deliver drier mixes.

Sixth, it’s crucial to monitor the mixing process! Operators must ensure consistency and quality by observing the mixing process. They may need to make certain adjustments by adding more water, tweak material ratios, etc.

Seventh, it’s time to discharge the concrete. After the mixing process ends, the operator stops the drum and ports the trolley type concrete mixer machine near the target area. The drum undergoes careful tilting with the help of a handle or lever so that the concrete flows out of the drum and falls onto the desired location.

Eight, you can also transport the concrete mix. Since there’s a trolley frame for moving the mixer around, use it to apply the concrete over different locations, all within a single time frame!

Finally, cleaning and maintenance are paramount! After each use, operators should thoroughly clean the trolley-type concrete mixer machine to prevent unnecessary residue, which can affect future concrete batches.

Along with the mentioned steps, it is crucial to follow safety guidelines and wear appropriate personal protective equipment when using the trolley-type concrete mixer machine.

Where Is the Trolley Type Concrete Mixer Most Applicable?

The trolley type concrete mixer machine has become an indispensable tool in those scenarios that focus on portability, mobility, and the need for small to medium-sized concrete batches.

Here are the most prominent usage-case scenarios of this fascinating product:

It’s a game-changer for small construction sites: Minute sites make great use of the trolley type concrete mixer machine because of limited space and low requirement of the volume of concrete.

It can help remote locations: This technical marvel goes places where traditional batching plants cannot! They are the go-to solution for hard-to-reach areas.

It can assist in renovation and repair work: The trolley type concrete mixer machine can patch concrete surfaces or pour small foundations, making it a primary tool for renovation.

It can contribute to landscaping projects: The mixer is indispensable for landscaping tasks such as creating pathways, garden borders, or decorative concrete features.

It assists DIY projects: The trolley type concrete mixer machine is crucial for homeowners carrying out small-scale concrete work, such as creating stepping stones in the backyard or pouring footings for sheds.

It also performs the role of an on-site tester: Some sites require specific concrete, which is impossible to forge on the go if concrete comes from a batching plant. The machine is a revolutionary asset in this field as it can conduct efficient on-site testing with trial batches!

Note: Never use the trolley type concrete mixer machine for high-volume concrete production or large-scale construction projects! In such cases, stationary batching plants or larger concrete mixers are the appropriate solutions.

What Are the Advantages of the Trolley Type Concrete Mixer?

The trolley-type concrete mixer machine is a beneficial champ! It offers many advantages over its traditional competitors, making it an ever-relevant product for endeavors in the construction industry. They are a practical choice for specific construction scenarios, primarily focusing on small-scale projects.

First, the machine reduces transportation costs! Since it comes with wheels, the trolley type concrete mixer machine removes the need for excess manual labor and speeds up the mixing process.

Second, it’s space-efficient by design. If a construction site is suffering from a lack of space or has tight access points like interior areas or narrow alleys, the machine can reach these areas because of its compact design.

Third, it’s a versatile product. The trolley mixer is not limited to one task; it can assist in construction projects and DIY endeavors focusing on light construction work. It also works as an experimental tool for trial batches!

Fourth, the trolley type concrete mixer machine is cost-effective. The mixer is cheaper than larger concrete batching plants or truck-mounted mixers. And because of its efficiency, it also reduces material waste, thereby reducing environmental impact.

Fifth, it is easy to use. The trolley type concrete mixer machine is relatively easy to operate, so expect its accessibility to attract a wide range of users, including homeowners and small contractors.

Finally, it is easy to maintain. The machine is not a hassle to repair or clean, but you must keep the maintenance cycle in regular flow, or it will stop performing according to its best results

As India continues to ride the upward momentum, different projects have come to the fore, asking for varying product specifications to raise ideal infrastructure. But, the trolley type concrete mixer machine is a hero that seeks to eliminate this need by acting as the go-to product across several scenarios!

It rocks mobility, efficiency, and versatility, making it a paramount machine in lending supreme-quality concrete for small-scale DIY projects or light commercial construction work. If you’re looking for a trolley type concrete mixer machine, relax! We’ve got the best ones available!

Lotus Traders boasts a healthy catalog of the finest industrial equipment, such as premium trimix systems, brick molding machines, and all types of concrete mixers. Hop over by our shop today to find the ideal product of your dreams!

Frequently Asked Questions

A trolley-type concrete mixer machine has a unique trolley mechanism that accelerates portability and reduces the need for manual transportation of concrete from one area to another.

A trolley-type concrete mixer machine reduces transportation costs, provides space efficiency, and is cost-effective in maintenance, making it a popular choice compared to other mixers.

Traditional trolley-type concrete mixer machines can mix 63 to 68kg per batch, but this mixing capacity may vary by make and model.

Yes! Trolley-type concrete mixer machines are the ideal choice for DIY and small-scale projects.

Yes, a trolley-type concrete mixer machine is applicable for constructional repairs and patching minute work.

Yes! The trolley-type concrete mixer machine reaches places where conventional batching plants or large truck mixers cannot, making it the ideal choice for remote areas.

A traditional trolley-type concrete mixer machine can start from Rs. 20,000, but the higher-end variants can go beyond Rs. 85,000.

Yes, the trolley-type concrete mixer machine is relatively easy to operate, but it helps to understand proper manufacturing guidelines before using one.