Best Groove Cutting Machine in India

The groove cutting machine‘s 14-20-inch blades make it the primary choice for delivering finishing touches to several materials!

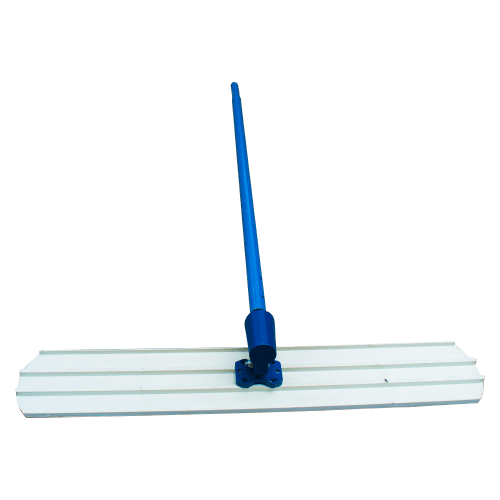

Groove Cutting Machine

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURES | SPECIFICATION |

Blade Size | 14 to 20 Inch |

Speed | 4200 RPM |

Weight | 85 KG |

Width | 15 Inch |

Driven By | Engine / Motor |

Power Required | 7.5 Hp / 10 Hp / 15 Hp |

What is a Groove-Cutting Machine?

The groove-cutting machine can cut grooves for contrasting materials like concrete, asphalt, wood, and metal. It is the ideal go-to choice in the construction and manufacturing industries but is also a popular bet for home improvement projects.

Most groove-cutting machines have a rotating blade, but newer, sophisticated models have integrated the technology of a laser guide to ensure a straight cut. They also come in different variants; concrete cutters are efficient in trimming concrete and asphalt, wall chasers are for brick and masonry, wood groovers are for joining wood, and metal groovers assist in metallic fabrication and assembly.

This article will touch on the primary aspects of a groove-cutting machine, its advantages over other construction equipment, and its unparalleled importance to the construction industry. Here we go!

Table of Contents

What Are the Key Features of the Groove-Cutting Machine?

Expect the groove-cutting machine to present many distinct features that make it a force to comprehend in raising supreme architecture towards the skies! While these features can make a lengthy list, let us narrow it down to the specifics:

The dedicated power source: This machine runs on an electricity or a gasoline-powered engine. A few variants run on compressed air! The type of power source needed usually depends on the material that needs cutting.

There are different blades for cutting: Different materials require separate blades for groove-cutting, such as diamond blades for concrete and asphalt, while carbide variants for wood and metal.

The cutting depth and width adjustment: No innovative product can live long in the market if it cannot promise versatility! Since a groove-cutting machine can change its cutting depth and width, it is compatible with alternating projects.

The integrated safety features: If you want to own a groove-cutting machine, always choose one with top-notch safety features, such as a blade guard and a dust collection system.

Additional features you will come across in the most sophisticated models are a laser guide to ensure a straight cut, a water cooling system to prevent the blades from overheating, and variable cutting speeds to comply with many materials!

How Does the Groove-Cutting Machine Work?

The million-dollar question is here – how does a groove cutting machine work? It’s not rocket science, per se, but a fascinating device to work with!

The machine uses a rotating blade to cut a groove into a material under the power that comes from an electric motor or a gasoline engine. The operator can adjust the groove’s depth and width by changing the blade’s position.

First, once the desired location gets marked on the material, the blade is lowered into it. The operator slowly guides the machine along the marked line to cut the groove. Once the material reaches the desired cut, it becomes compulsory to remove the groove cutter.

In case we did not make the process blunt, here’s a simple list underlining the steps:

- The user turns the machine on and sets the required cutting depth and width.

- The user positions the groove-cutter over the desired location.

- The user lowers the machine’s blade into the material.

- The user slowly guides the groove-cutter along the groove’s ideally required path.

- Once the cutting process is over, the user removes the groove-cutter!

Please remember that the groove cutting machine is not a playtoy; it can be dangerous if operated without proper inspection. One should wear appropriate safety gear and comply with the manufacturer’s instructions before working with this machine.

Where Is the Groove Cutting Machine Applicable?

The groove-cutting machine is a highly compatible device for several usage-case scenarios. It has become an asset for different projects that prioritize aesthetics with durability.

Here are a few applicable areas where the groove cutting machine excels, although the list is not exhaustive:

Construction endeavors: The construction industry needs this machine to cut grooves for electrical wiring, plumbing pipes, and expansion joints.

Manufacturing processes: Several manufacturing industries require cutting grooves in wood, metal, and plastic for joinery, fabrication, and assembly.

Road maintenance: Roads need grooves in the asphalt and concrete to improve drainage and traction and to prevent waterlogging.

Floor preparation: The floor preparation industry uses the groove cutting machine to create a level surface for flooring materials.

Home improvement: To improve the aesthetics of a home, homeowners can use the machine to cut grooves for electric wiring or plumbing pipes!

What Are the Advantages of the Groove-Cutting Machine?

One can expect many distinct advantages from a groove cutting machine while building stable architecture. We will seek to extrapolate all those benefits in concise terms below:

It offers aggressive precision. The machine does not compromise in terms of accuracy! This peak calculation for delivering finely cut grooves is beneficial for adjusting electrical wiring and plumbing pipes.

It is ruthlessly efficient! The machine is quick to advocate for efficiency. This reliability makes it a crucial factor for high-volume applications, such as providing grooves in concrete for expansion joints.

It is massively versatile. Not only concrete but even other materials like asphalt, wood, and metal depend on the capabilities of the groove cutting machine.

It reduces labor costs by competitive margins. A machine exists to elevate the hardships of manual labor, and the groove cutter aspires to do so by automating the cutting process and reducing labor costs.

It improves a project’s quality and productivity: The machine delivers high-quality grooves with a consistent depth and width. It also increases productivity by reducing the time required to cut grooves!

Overall, groove cutting machines win the game of efficiency over traditional methods of cutting grooves. They offer precision, efficiency, versatility, and a safe working environment!

What Makes the Groove Cutting Machine Unique?

The unique properties of the groove-cutting machine stand tall because they carry out distinct work that other construction equipment may not be capable of doing.

Precise grooving is the primary trait of why this machine holds its ground, and adding specific depth and width to the process while adhering to project requirements is the icing on the cake!

Modern models have knocked the ball out of the park with state-of-the-art technological features like sharp laser guides to assist in the cutting, convenient water cooling systems to prevent the blades from overheating, and variable speed to control the cutting speed flow. It is better to opt for the higher-end variants when making a purchase choice because the extra features alleviate the worthiness of the final package!

Therefore, if you need to cut a groove in a material, our industrial experts recommend the groove cutting machine as the best tool for completing the job. It is valuably versatile and will never compromise on your grooving needs while consciously attempting to avoid repair and maintenance costs along the way!

Are you in need of a groove cutting machine? Do you aspire to buy or rent one for your next project? Are you looking to make aesthetically pleasing surface designs without compromising their quality and reliability? Do you want your next project to stand out with finely trimmed grooves on your walls and floors? Lotus Traders has all the answers!

We own the finest groove-cutting machine models the construction industry has produced, ranging from the lower-end models to the most sophisticated variants. Besides groove cutters, we also deal in other construction-related equipment like premium trimix systems, vibrator machines, earth compactors, concrete mixer machines, etc.

If you’re searching in the saturated market for the ideal products to assist your construction endeavors, visit Lotus Traders today for many exclusive deals!

Frequently Asked Questions

The groove-cutting machine can cut grooves for contrasting materials like concrete, asphalt, wood, and metal. According to experts, it is the ideal go-to choice in the construction and manufacturing industries but is also a popular option for home improvement projects.

A traditional miniature variant may start from Rs. 9,000, but the higher models can exceed Rs. 1,00,000!

Lotus Traders owns the finest groove-cutting machine models the construction industry offers, ranging from the lower-end models to the most sophisticated variants. Besides groove