Best Plate Vibrator in India

Experience the unparalleled power of the plate vibrator with its 5200 RPM compensating for your compaction needs!

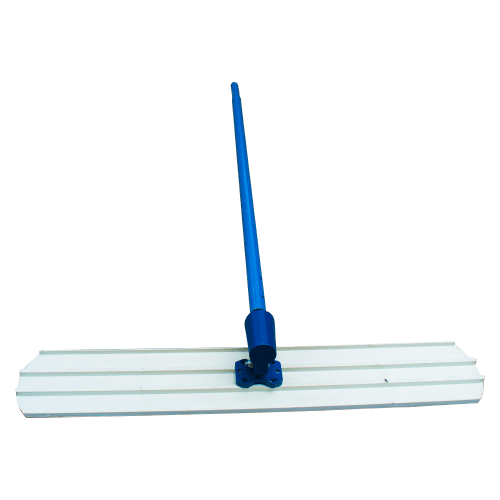

Plate Vibrator

- High quality materials

- Compliance with Standards

- Clear Product Information

- Warranty & Support

- Product Testing & Certification

- Delivery & Policy

- Ask a Question

- Estimated Delivery: 5 Days – 10 Days

- DESCRIPTION

FEATURE | SPECIFICATION |

Material | Stainless Steel |

Speed | 1500 RPM |

Motor | 1.6 HP |

Engine Power | 1 HP |

Weight | 25 KGS – 35 KGS |

Fuel Tank Capacity | 0.65L |

What Is a Plate Vibrator?

The plate vibrator is a reliable construction machine for compacting soil, gravel, asphalt, or other materials to achieve a denser and more stable surface. It is the practical choice for large-scale construction projects to prepare stable ground for foundations, road surfaces, walkways, and other structures.

This plate compactor is not a small product; it has a gigantic steel plate mounted on a vibrating mechanism that transmits waves to the ground through the plate’s base. This procedure compresses the loose materials and eliminates air voids to increase material density.

We have brought forward this article for the general audience to understand the primary aspects of the surface vibrator, its applicable scenarios, and its dependent efficiency in the construction industry. Have a read

Table of Contents

What Are the Key Features of the Plate Vibrator?

The plate-vibrator has other names – it also identifies as a plate compactor or a vibratory plate compactor. The most typical features you will come across all plate vibrators in the market are as follows:

The existent vibrating plate: This plate is the primary component of the machine! It makes direct contact with the material to carry out compaction. It’s also built robust enough to withstand the forces generated during the process.

The vibrating component: The vibrating equipment is necessary to generate rapid vibrations in the plate. It depends on an internal combustion engine to carry out the process.

The handlebar: All plate vibrators have a handlebar to allow the operator proper control over the machine. This bar is adjustable and sometimes foldable, allowing for convenient transport and storage.

The dedicated throttle or engine controls: The plate compactor has specific engine controls for the operator to tinker with the machine’s speed and start-stop applications.

The centrifugal force: Centrifugal force is the physical drive spurning the plate to cause upward and downward movement.

The transport wheels: Since the plate compactor models are tedious in portability, manufacturers integrate them into adjustable wheels to make the transportation process more convenient.

Other aspects you will never miss on a surface vibrator are greater directional control, a water system to wet the material, sophisticated safety features, etc.

How Does the Plate Vibrator Work?

The plate vibrators working structure is straightforward, as it generates vibrations to compact soil, and the operator has to control the machine to achieve the desired target results. We have extrapolated a step-by-step explanation of how this technical marvel works:

First, turn on the power source. The initial step is to start the engine and apply a preset level to adjust the throttle or speed control to the desired level.

Second, the plate has to make contact. The heavy steel plate attached to the machine’s base makes contact with the material that needs compaction. This material can vary; it might be soil for a foundation, loose gravel for a driveway, freshly laid asphalt for a road, etc.

Third, the vibration begins. Once the engine starts, the vibrating component generates rapid vertical shuddering, causing the plate to move up and down very quickly.

Fourth, the centrifugal force comes into play. The plate’s rapid movement generates centrifugal force, which gets directed downward. This force assists in pushing the plate further deep into the material, effectively compacting it.

Fifth, the operator needs to maintain control. The operator has to guide the handlebar during the operation to control its movement and direction. They can walk behind the machine and usher it towards the desired areas, ensuring even compaction.

Sixth, there’s a forward and reverse design! Today, most plate vibrators facilitate moving in both forward and reverse directions, allowing the operator to move the machine swiftly toward all corners.

Seventh, it’s crucial to carry out multiple passes. This step is paramount to achieve the desired compaction level. Different materials require varying numbers, and the compaction specifications of the project equally matter.

Eight, there’s an optional step! In specific cases, the surface vibrator may boast a water tank or a sprinkler system to wet the material while it undergoes compaction.

Finally, it is imperative to understand and observe all safety precautions before putting the plate compactor to work. Site experts wear appropriate personal protective equipment (PPE) and maintain proper footing to ensure uncompromised safety.

Where Is the Plate Vibrator Applicable?

The plate vibrator is a massively versatile tool, making it the primary choice for numerous construction projects. Here is an extensive list expressing the machine’s usage-case scenarios:

It is for preparing foundations: The surface plate vibrator is essential for preparing the ground before pouring concrete foundations for buildings, retaining walls, or other structures. Weak soil will lead to unspeakable mishaps!

It’s crucial for constructing roads: Roads, highways, driveways, and parking lots need well-compacted sub-bases to ensure durable and smooth surfaces.

It is for paving projects: The plate compactor is handy for compacting crushed stone or gravel before laying asphalt or concrete over it.

It assists landscaping: Landscaping projects need the plate compactor to create level surfaces for patios, walkways, and garden paths. It also compresses the ground around plantings or retaining walls.

It helps during trench backfilling: Water and sewer lines need adequately dug trenches with properly compacted backfill material. This benefit is to ensure the backfilling is well-settled.

It’s essential for repair and maintenance: Not only does the surface vibrator create, but it also amends! This machine can repair already-built paved surfaces, such as filling potholes and compacting asphalt patching materials.

It solidifies sports fields: Prepping the ground for sports fields and arenas is necessary to ensure firm and level playing surfaces.

This list is not a roundup; the plate compactor has so many more applicable situations we will get exhausted talking about them! It is crucial for other scenarios like brick and paver installation, constructing burial plots and pathways within cemeteries, creating paths in agricultural settings, etc.

Let us round off by saying the specific application of a plate vibrator will always depend on the project’s requirements!

What Are the Advantages of the Plate Vibrator?

Many advantages underline the proficiency of the plate vibrator across several fields, such as construction, landscaping, filling, etc. A few benefits propelling its efficiency to god-tier status are:

It promises efficient compaction: The surface vibrator will not compromise your construction needs! It can finely compact the material and present you with stable, load-bearing surfaces.

It spurns versatility: The machine works to compact different materials, including soil, gravel, sand, asphalts, and pavers, making it a versatile tool across landscaping projects.

It delivers quick results: The plate compactor is a quick-operation tool. It reduces the time and labor for many compaction tasks and increases productivity.

It promises uniform compaction: Variations in material density may occur under manual labor, but the surface vibrator leaves no margin for such errors.

It reduces air voids: The vibrations are a medium to eliminate air voids in the material, thereby increasing its density and strength.

Other offerings the plate vibrator brings to the discussion are easy maneuverability, reduced labor costs, low maintenance, and world-class safety features!

In essence, the plate vibrator embodies a cornerstone of modern construction practices, offering a combination of efficiency, versatility, and reliability that is indispensable for building solid foundations and long-lasting structures, making them a linchpin in the construction industry. If you want to buy a plate surface vibrator for your next project, we might have the best deals available!

Lotus Traders has embraced the ins and outs of the construction industry since 2009 and has become the number one player in dealing with the best construction-related equipment available.

Besides plate vibrators, we maintain stock of other equipment like concrete mixers, brick molding machines, premium trimix systems, etc. Visit our shop today to engage with our catalog’s finest offerings!

Frequently Asked Questions

The plate vibrator is practical for compacting soil, gravel, asphalt, or other materials to achieve a denser and more stable surface. It is the go-to choice for large-scale construction projects to prepare stable ground for foundations, road surfaces, walkways, and other structures.

Cheaper variants of the plate vibrator can start around Rs. 12,000, but expect the higher-end models to exceed Rs. 40,000!

The plate vibrator promises efficient compaction, encompasses versatility, accelerates project timelines, and reduces air voids on surfaces!

Lotus Traders has the finest plate vibrator models available! Visit us today for a personal browsing experience that aligns with your needs.

Yes! We own the plate vibrator and will gladly provide a personal walkthrough of its variants!

A plate vibrator is highly technological. Therefore, expect veteran expertise to propel it to maximum efficiency. However, a little bit of practice will turn your fortunes inside out!

A plate vibrator is highly sophisticated, so it is best left to the industrial experts to operate it. However, proper training and following manufacturer protocols will alleviate the learning experience for beginners!